Weight compensation device on underframe of elevator carriage

The technology of a compensation device and a car bottom frame is applied in elevators, transportation and packaging, elevators and other directions in buildings, which can solve the problems of inability to apply balance iron or counterweight block installation and fixation, and limited range of car weight compensation. To achieve the effect of convenient installation and fixation, reducing wear and tear, and large compensation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

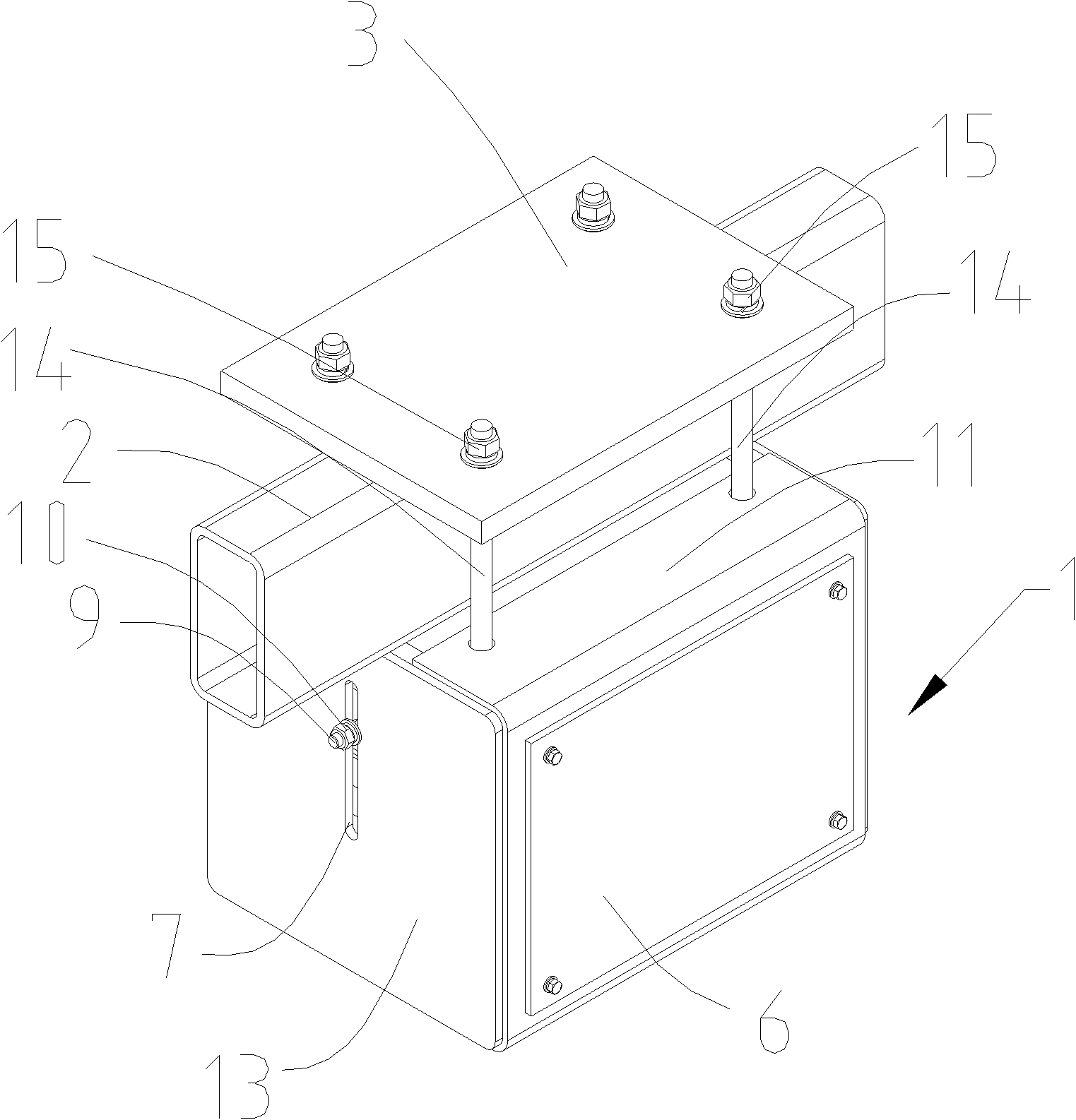

[0017] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

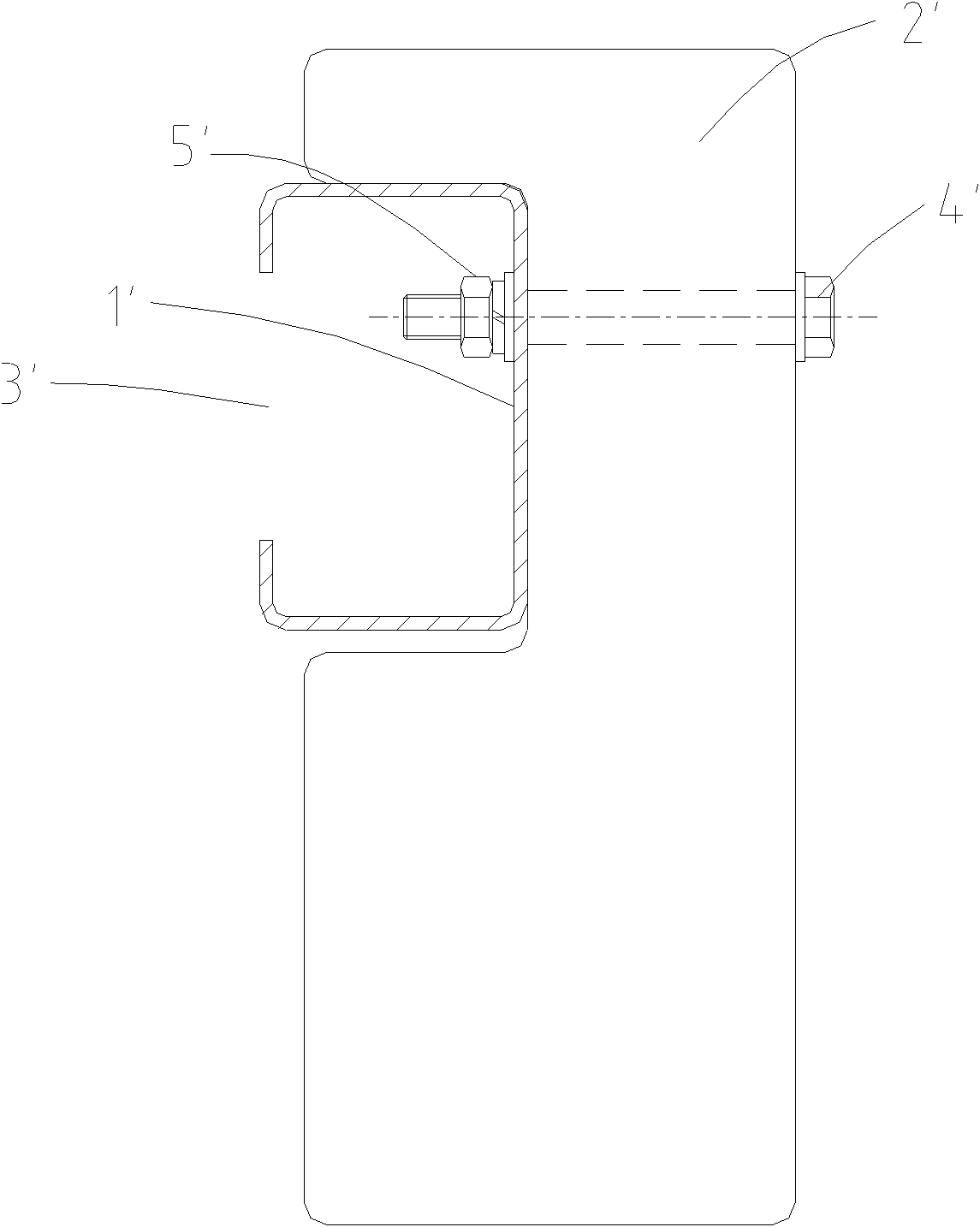

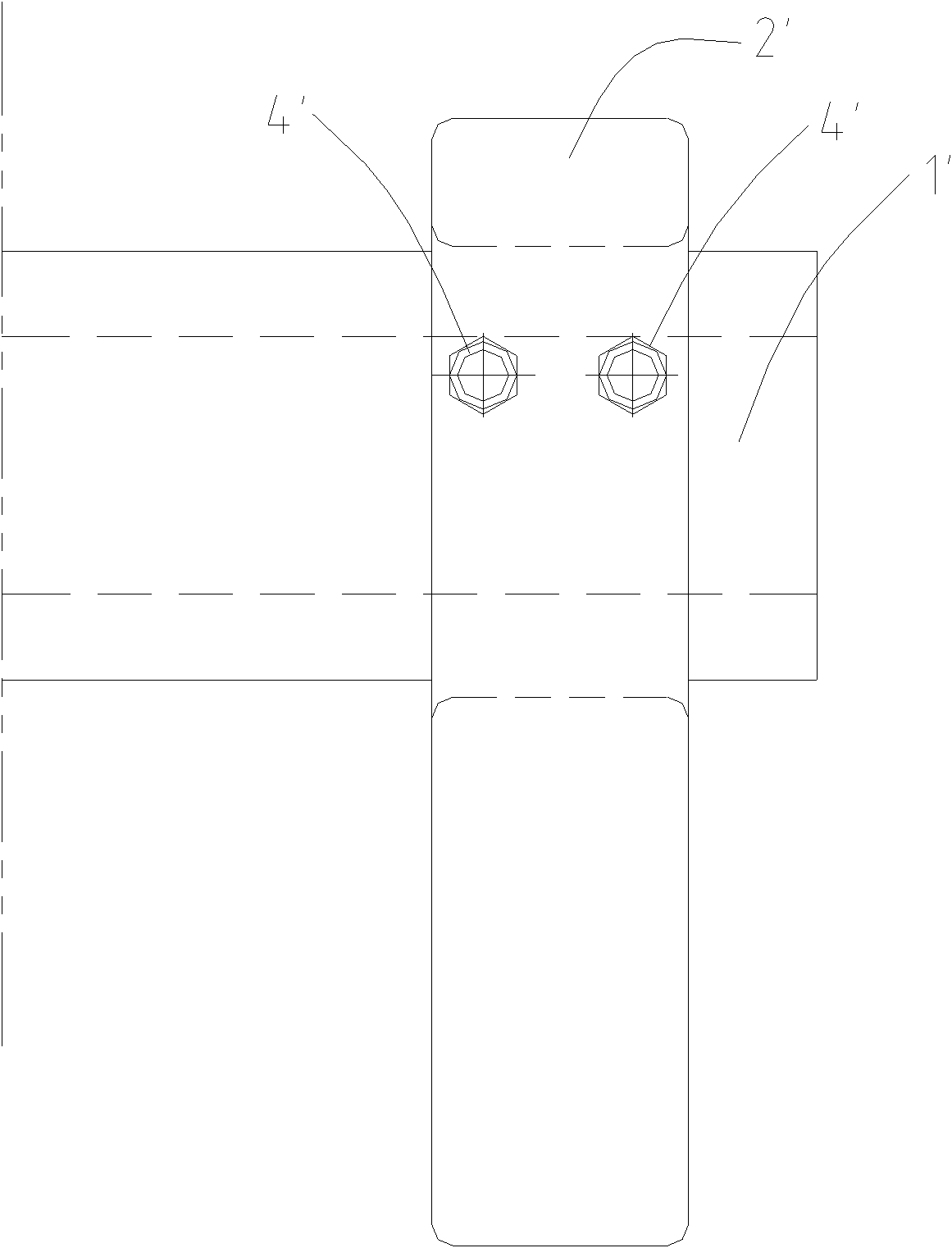

[0018] see Figure 3-4 As shown, the weight compensating device on the elevator car chassis includes a car chassis 2, a box body 1 with an inner cavity 16, an opening 5 communicated with the inner cavity 16 provided on the box body 1, and the opening 5 can be detachably covered. The cover plate 6, the counterweight 4 can be placed in the inner cavity 16 of the box body 1, the size of the opening 5 should be able to allow the counterweight 4 to pass through, and the box body 1 can clamp the car floor separately by cooperating with the connecting plate 3 Rack 2. Place a plurality of counterweights 4 in the box body 1, and the box body 1 and the connecting plate 3 cooperate to clamp the car frame 2, so as to realize the connection of the box body 1 equipped with a plurality of counterweights 4 on the car bottom frame 2 fixed, so that the weight of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com