Welding device capable of being overturned automatically

An automatic flipping and welding device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high labor intensity of workers, achieve the effects of saving manpower and operating time, beautiful products, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

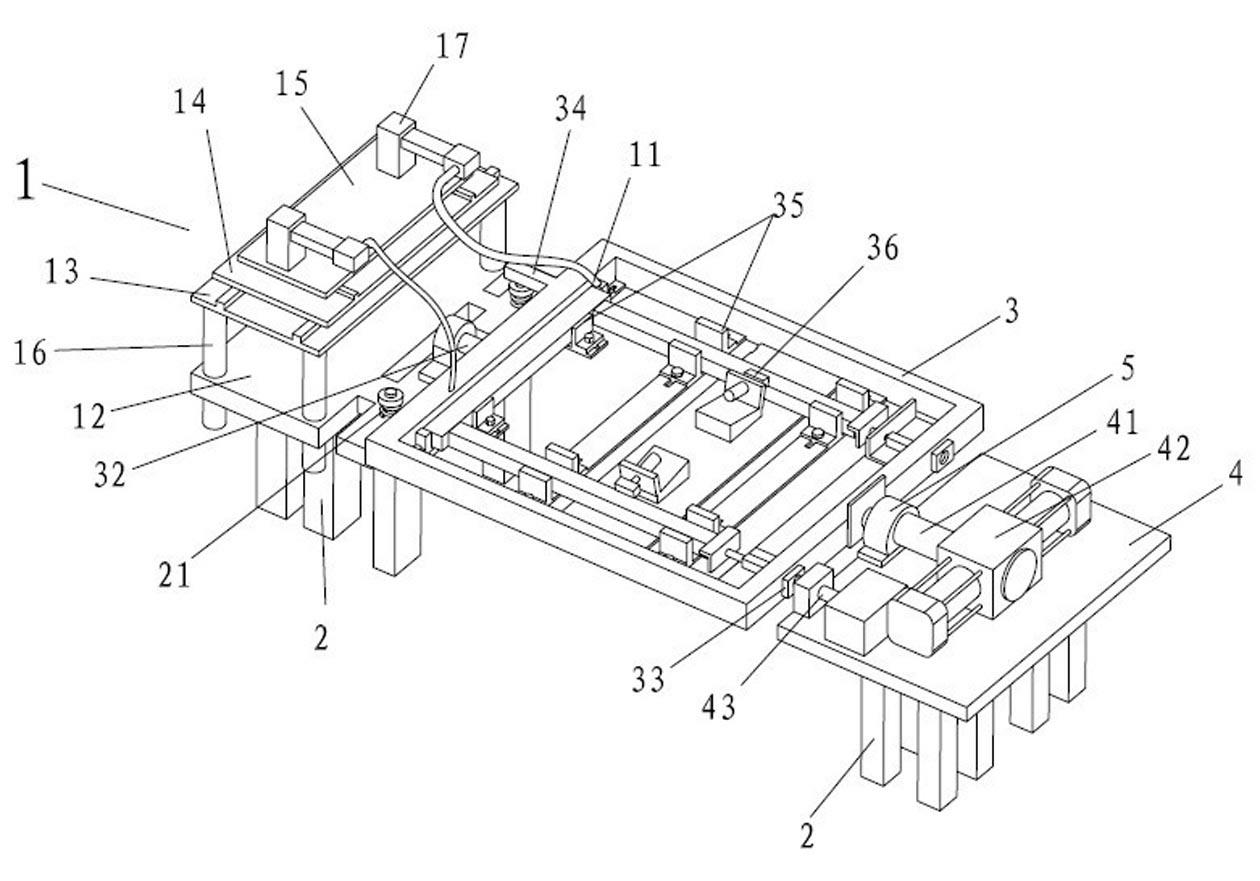

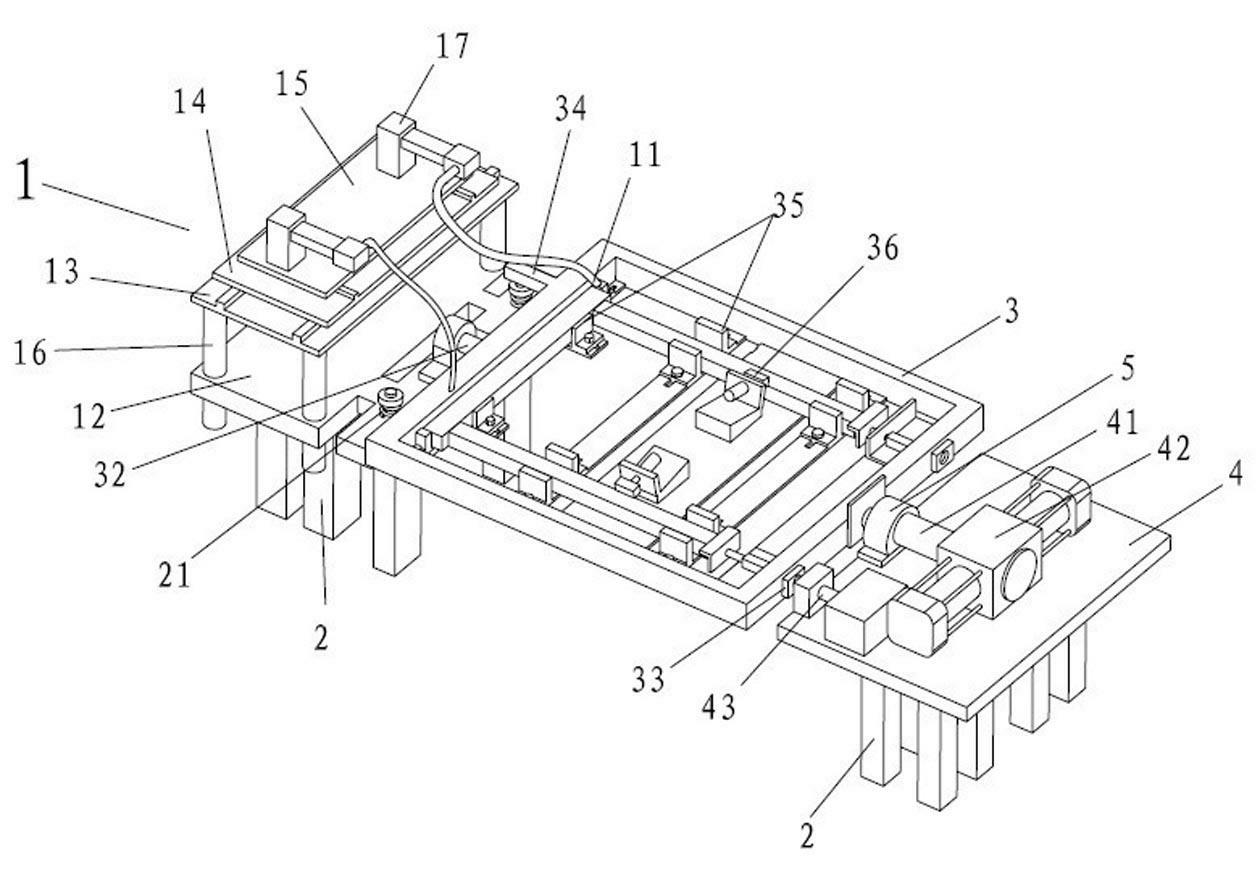

[0020] As shown in the accompanying drawings, a kind of automatic turning welding device comprises welding assembly 1, automatic turning assembly and support 2, and welding assembly 1 and automatic turning assembly are arranged on the support 2, and welding assembly comprises movable welding torch 11; Automatic turning assembly comprises The turning platform 3 and the driving platform 4; the turning platform 3 is provided with a positioning system for fixing steel parts; the turning platform 3 is provided with a rotating shaft 32 at both ends, and the driving platform is provided with a driving system connected with the rotating shaft 32; it also includes Locking system for securing the flip platform 3.

[0021] The driving platform 4 and the bracket 2 are provided with a bearing seat 5, and the rotating shaft 32 is connected with the bearing seat 5; the driving system includes an electric shaft 41 and a turning cylinder 42 connected to the electric shaft 41, and the electric s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com