Degassing device for liquid-filled chambers with rotating components

A technology of exhaust device and rotating component, which is applied to components of pumping device for elastic fluid, liquid fuel engine, pump element, etc. gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

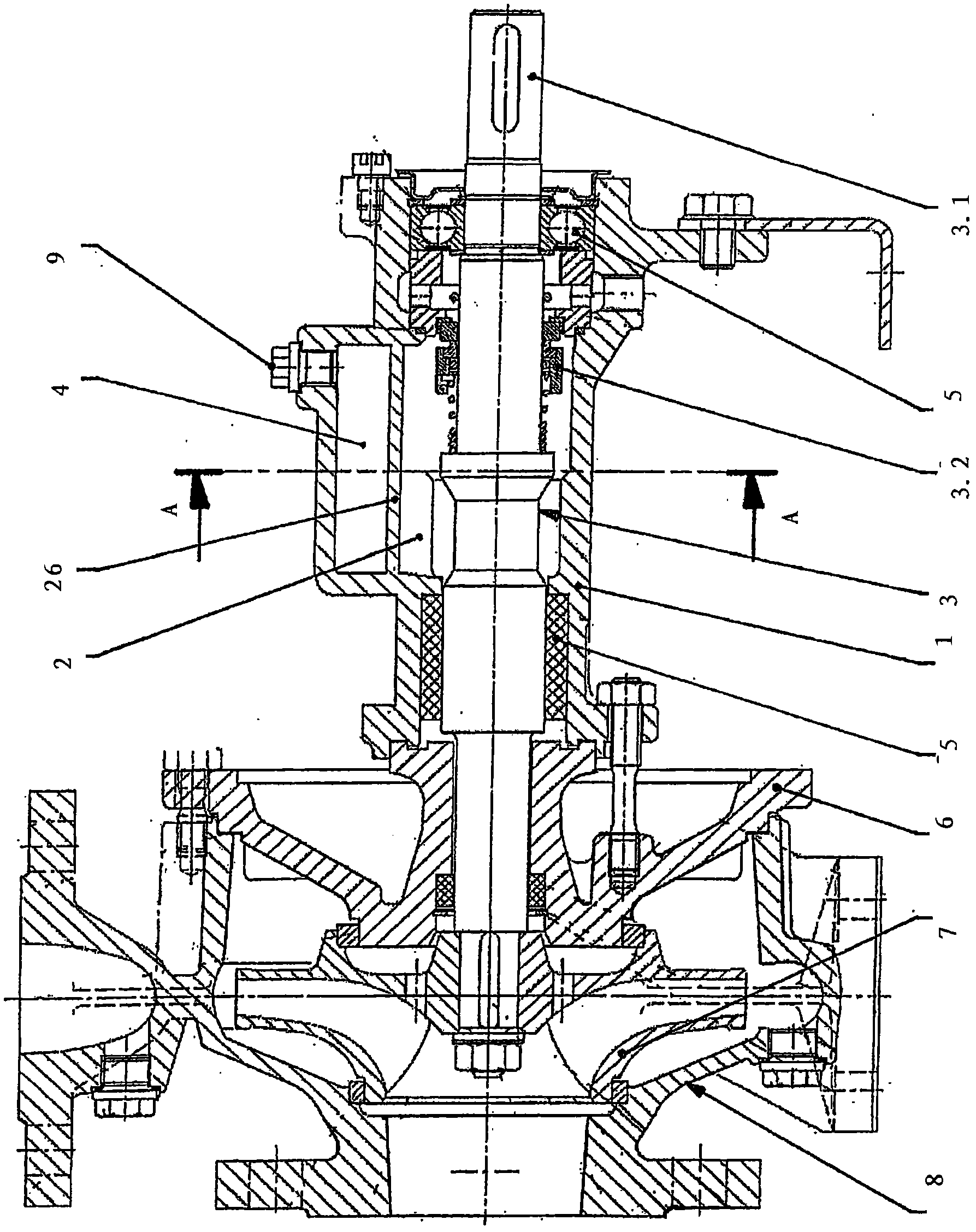

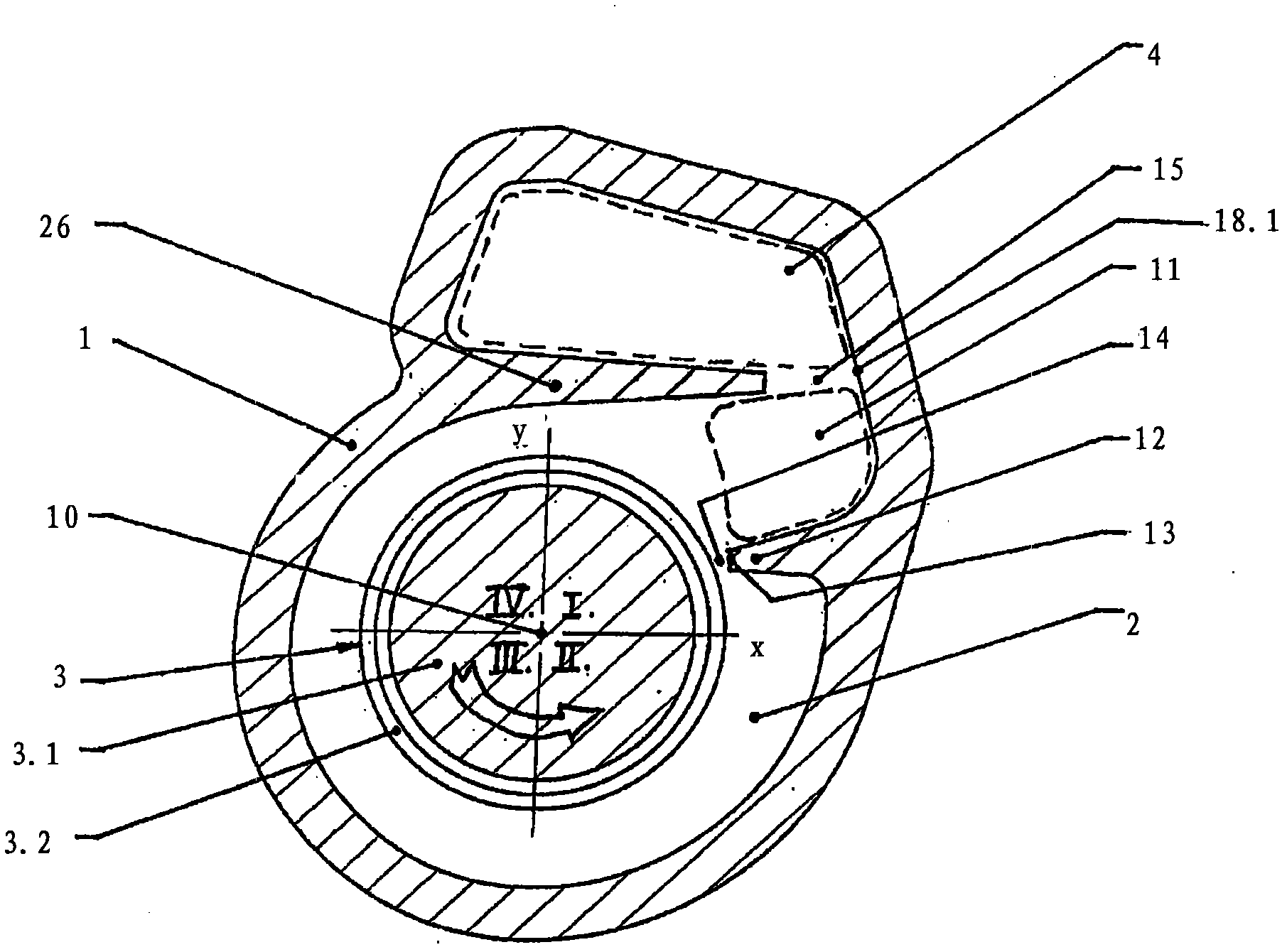

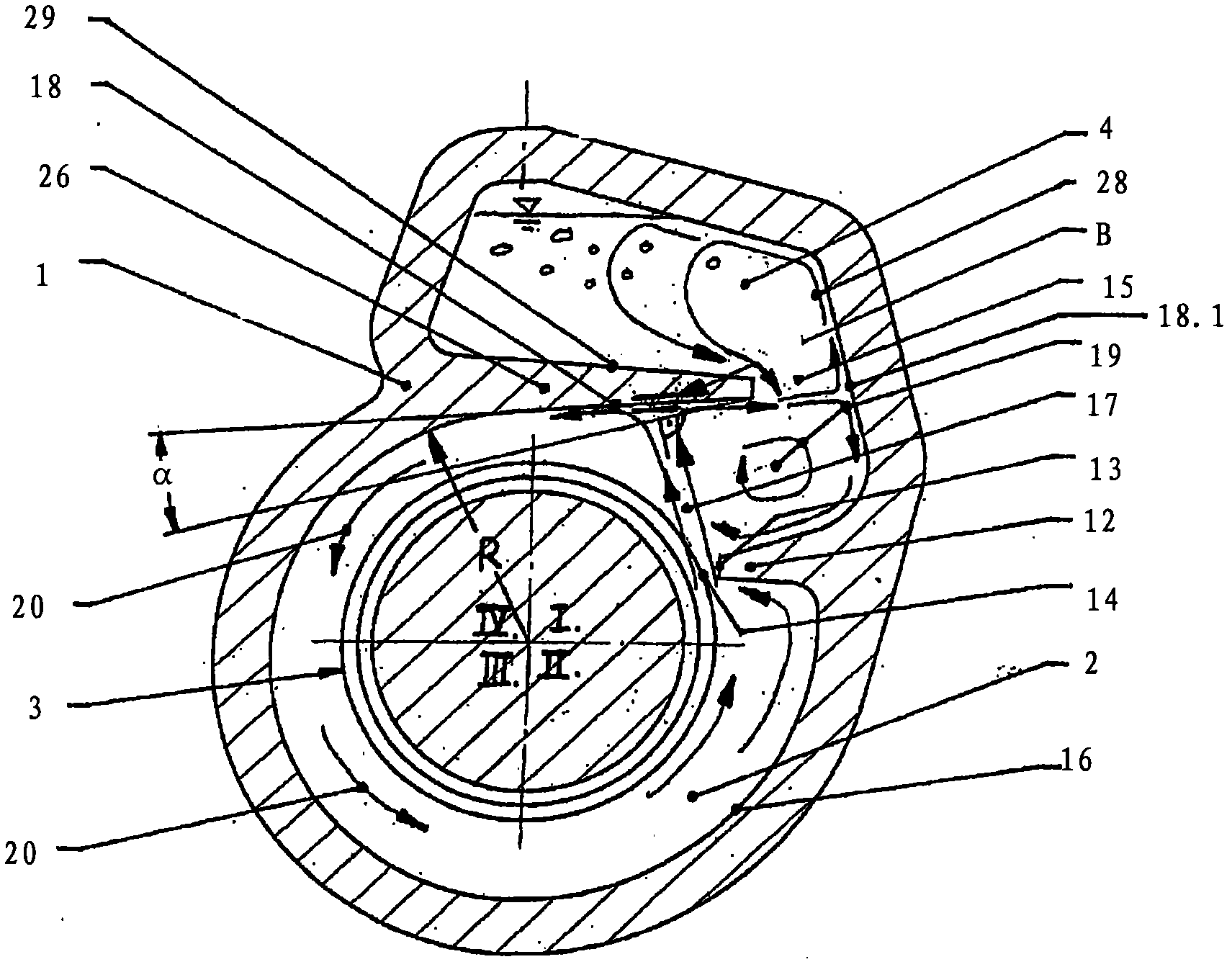

[0022] exist figure 1 The exhaust device for a centrifugal pump is shown in the example of a drive shaft. The exhaust device is arranged in a housing 1 and has a chamber 2 with a rotating component 3 arranged therein. This is a shaft 3.1 and a shaft seal 3.2 mounted thereon, which is formed as part of a slip ring seal. In this sectional depiction can be seen the exhaust chamber 4 mounted on the upper part of the shaft 3.1, delimited from the chamber 2 by the element 6 explained below. The shaft 3 . 1 held in the bearing 5 passes through the pump cover 6 and carries the impeller 8 of the centrifugal pump 8 . The liquid located in the centrifugal pump flows along the axis 3.1 into the chamber 2 of the exhaust device.

[0023] If there is no exhaust and there is gas in the chamber 2 or inside the liquid, the gas will collect directly on the rotating member 3 due to the difference in density and under the influence of centrifugal force. In contrast, the liquid rotates around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com