Medium-temperature and high-temperature solar heat collector tube exhaust method and device

A technology of solar heat collecting tubes and exhaust devices, which is applied in the direction of solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problem that the vacuum life and product quality cannot be further improved, the vacuum degree of medium and high temperature solar heat collecting tubes cannot be improved, and the vacuum degree cannot be fully Exhaust gas and other problems to achieve the effect of shortening the cooling time, exhausting thoroughly, and quickly exhausting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

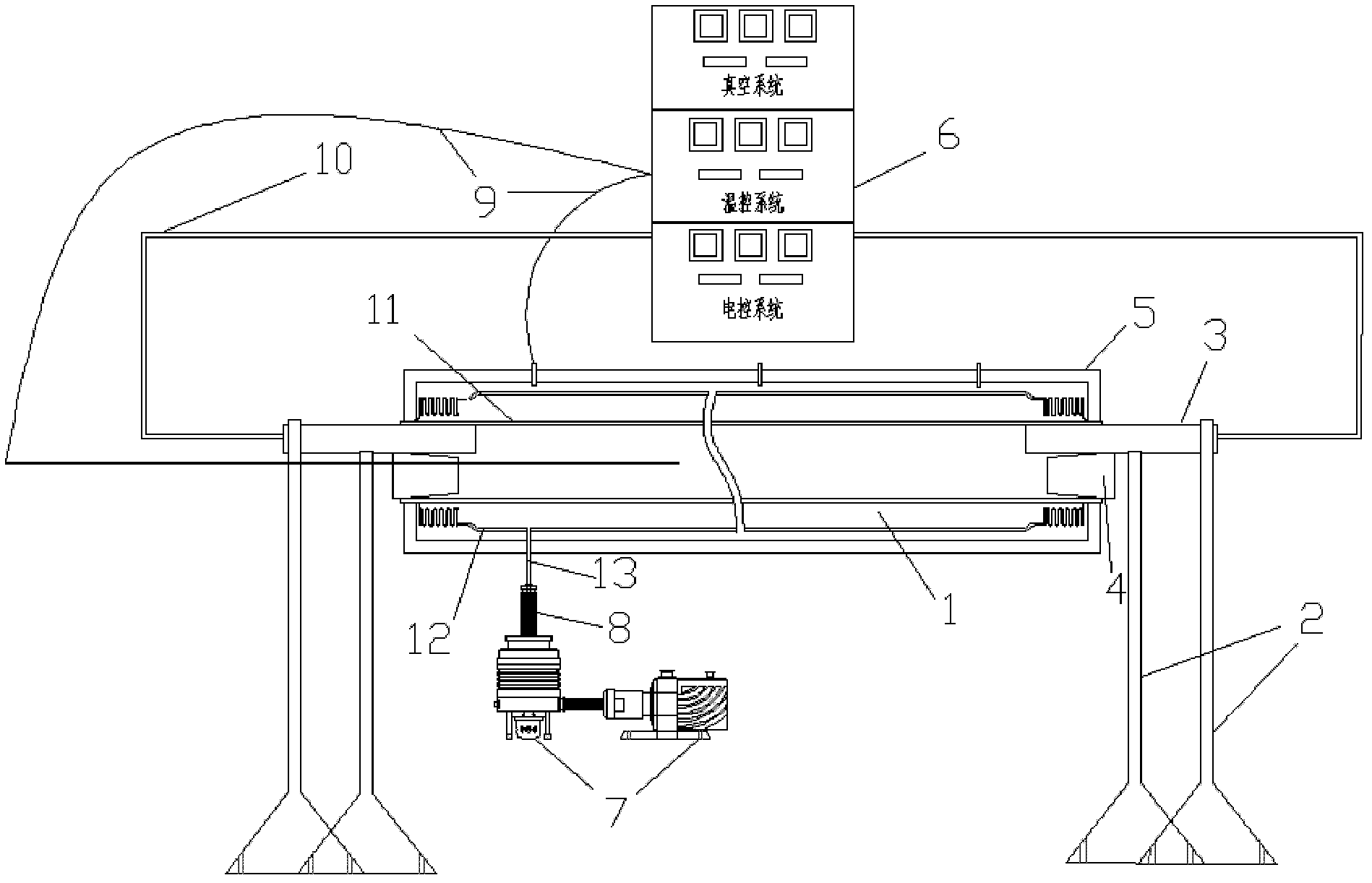

[0040] like figure 1 , 3 , 4, the connecting conductive tooling 3 is horizontally fixed on the bracket 2, the connecting conductive tooling 3 is a semi-cylindrical body, and the outer radius is equal to the inner radius of the metal inner tube 11 (such as image 3 , 4 shown), the surface is flat without pits, made of stainless steel, which is the same material as the metal inner tube 11; the main body of the bracket 2 is made of stainless steel, and the insulating part is ceramic to ensure the rigidity and insulation of the bracket 2; On the bracket 2, the connecting conductive tooling 3 is fixed in close contact with the inner wall of the metal inner tube 11, and the position is adjusted to ensure that the tail pipe 13 is vertically downward; the wire 10 is embedded in the connecting conductive tooling 3 and fixed with bolts, and the wire 10 is made of copper tape Or copper rods, plug both ends of the medium-high temperature solar collector tube 1 with asbestos plugs 4, wra...

Embodiment 2

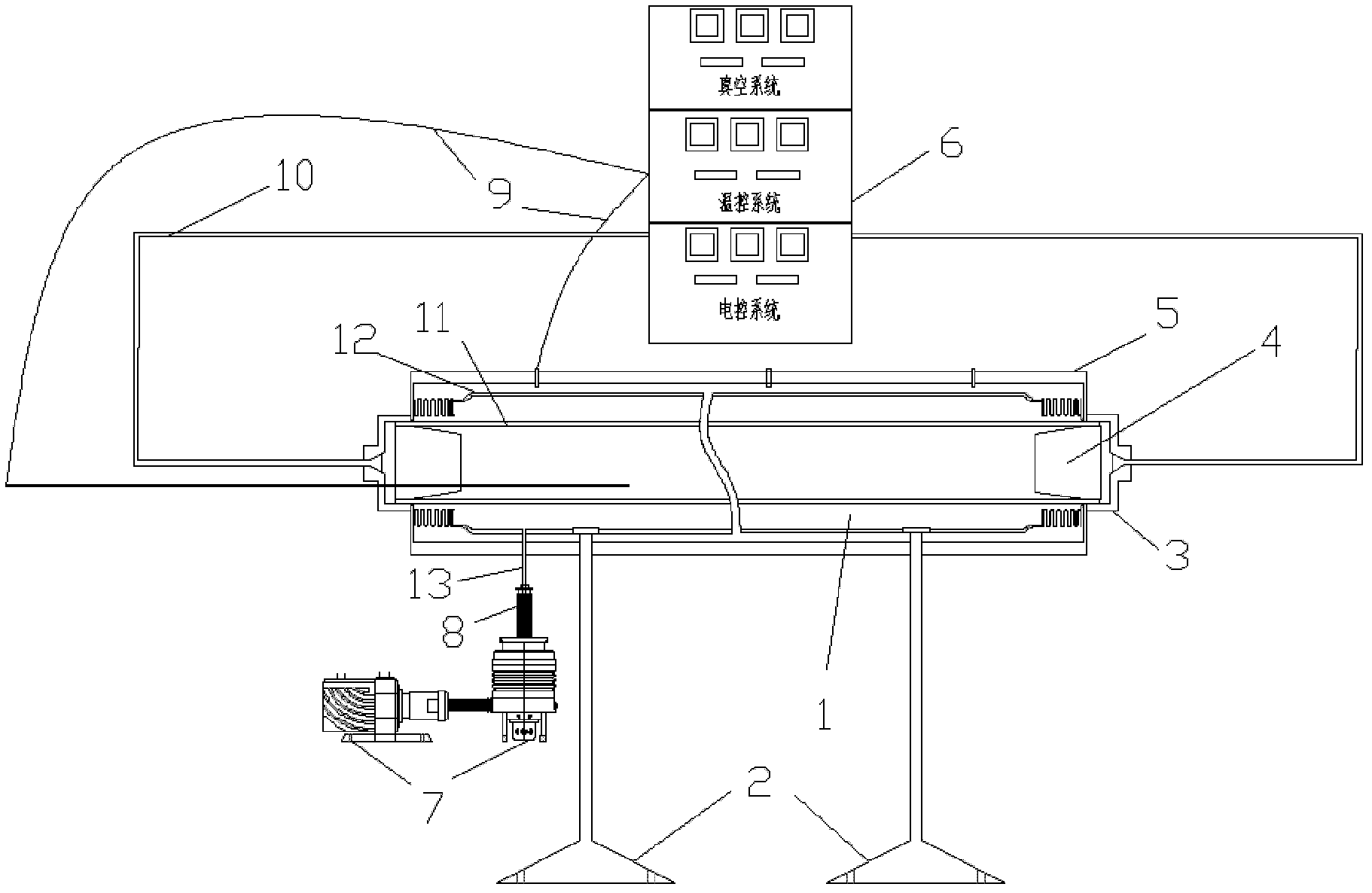

[0042] like figure 2 , 5 As shown, the thermal insulation tooling 5 is fixed on the bracket 2. The thermal insulation tooling 5 is made of a high temperature resistant mica board and filled with 10mm thick thermal insulation cotton. The main material of the bracket 2 is stainless steel, and the contact between the bracket 2 and the glass outer tube 12 is wrapped with asbestos tape wrapping; install the medium and high temperature solar collector tube on the bracket 2, adjust the position to ensure that the tail pipe 13 is vertically downward; plug the two ends of the medium and high temperature solar collector tube 1 with asbestos plugs 4, and use the thermal insulation tool 5 to cover the medium and high temperature solar collector The collector tube 1 is wrapped; one side of the connecting conductive tooling 3 is in close contact with the outer wall of the metal inner tube 11, and the other side is connected to the wire 10, and the connecting conductive tooling 3 is two sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com