Cylinder series connection elastic driver

A series of elastic and drive technology, applied in the field of drives, can solve the problems of difficulty, increase of drive processing and manufacturing, etc., and achieve the effect of small size, reliable performance and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

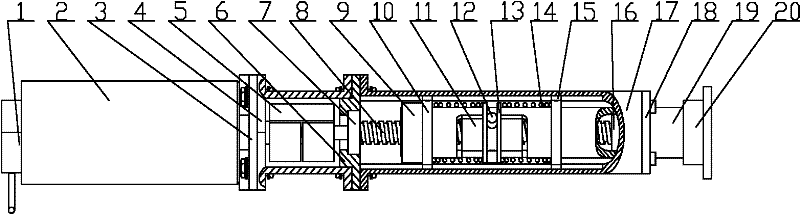

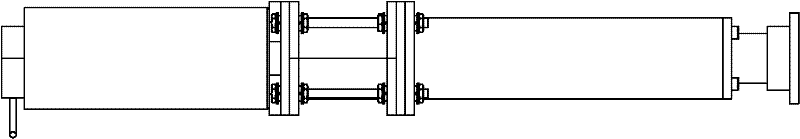

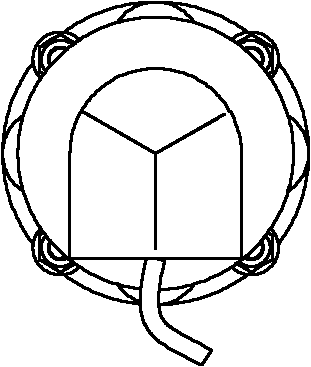

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0018] combine Figure 1~5 , the present invention is a motor-driven elastic driver, the end of the servo motor 2 is fixedly connected to the encoder 1, the other end of the servo motor 2 is fixedly connected to the motor support plate 3 through four screws, and the motor support plate 3 is fixed to the connecting cylinder 4 Connected, the connecting cylinder 4 is fixedly connected with the bearing seat 6, the bearing seat 6 is fixedly connected with the shell 17, the other end of the shell 17 is fixedly connected with the end cover 18, and the output shaft of the servo motor 2 is installed from the inside to the outside. Groove ball bearing 7, leading screw 8, support block 16, nut 11, thrust cylinder 12. The two sides of the thrust cylinder 12 connected with the nut 11 are two spring driving plates 13, and the two sides of the spring driving plate 13 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com