Forming mould for flue gas exhausting pipeline

A technology for forming molds and air pipes, which is applied in the direction of molds, vertical pipes, ceramic molding machines, etc., and can solve the problems of low product strength, low production efficiency, and easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

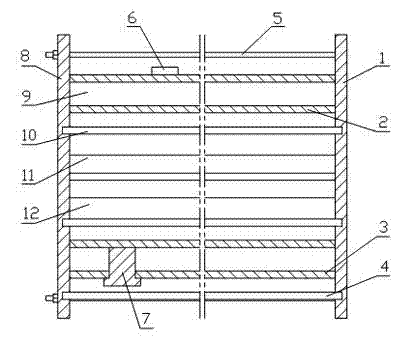

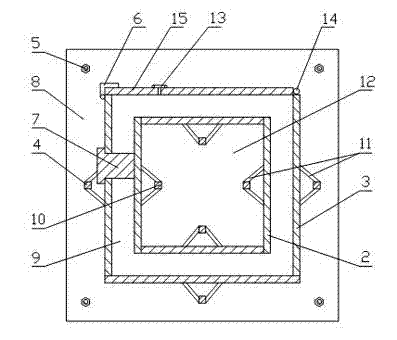

[0022] Example 1, such as figure 1 , figure 2 As shown, the exhaust gas duct forming mold includes a left frame 1 and a right frame 8, and a plurality of detachable outer templates 3 and inner templates 2 are arranged between the left frame 1 and the right frame 8. The detachable means: multiple outer templates 3 are respectively connected to the left frame 1 and the right frame 8 through fixing and limiting devices; multiple inner templates 2 are respectively connected to the left frame 1 through fixing and limiting devices with box 8 on the right. A plurality of outer templates 3 form an outer mold cavity, and a plurality of inner templates 2 form an inner mold cavity 12 in the outer mold cavity. A molding cavity 9 is formed between the inner and outer templates. The inner and outer contours of the cross-section of the molding cavity 9 are Square, at least one of the outer templates 3 is provided with a feed inlet 15, and the feed inlet 15 is provided with a door that can...

Embodiment 2

[0026] Example 2, such as image 3 , Figure 4 As shown, the exhaust gas duct forming mold includes a left frame 1 and a right frame 8, and a plurality of detachable outer templates 3 and inner templates 2 are arranged between the left frame 1 and the right frame 8. The detachable means: multiple outer templates 3 are respectively connected to the left frame 1 and the right frame 8 through fixing and limiting devices; multiple inner templates 2 are respectively connected to the left frame 1 through fixing and limiting devices with box 8 on the right. A plurality of outer templates 3 form an outer mold cavity, and a plurality of inner templates 2 form an inner mold cavity 12 in the outer mold cavity. A molding cavity 9 is formed between the inner and outer templates. The inner and outer contours of the cross-section of the molding cavity 9 are Square, at least one of the outer templates 3 is provided with a feed inlet 15, and the feed inlet 15 is provided with a door that can...

Embodiment 3

[0029] Example 3, such as Figure 5 As shown, the disassembly structure between the multiple inner and outer templates between the left frame 1 and the right frame 8 of the exhaust gas duct forming mold and the left frame 1 and the right frame 8, that is, the multiple inner and outer templates and the The fixing and limiting devices between the left side frame 1 and the right side frame 8 are the same as the aforementioned structures. The difference is that two inner mold cavities 12 are arranged in the outer mold cavity surrounded by a plurality of outer formworks 3. Of course, there can be more than two inner mold cavities 12 to form a conjoined smoke exhaust duct, and each inner mold cavity The shapes and sizes of the cavities 12 may be the same or different.

[0030] Such as Figure 6 The flue gas duct forming mold shown is provided with inner template grooves 20 and outer template grooves 19 for inserting multiple inner templates 2 and multiple outer templates 3 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com