Main platform splicing and constructing pneumatic tool assembly

A technology of pneumatic tooling and main platform, applied in the field of machining, can solve the problems of difficulty in ensuring the verticality of the side plate and the bottom plate, difficult welding quality, large weight and volume, etc. The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

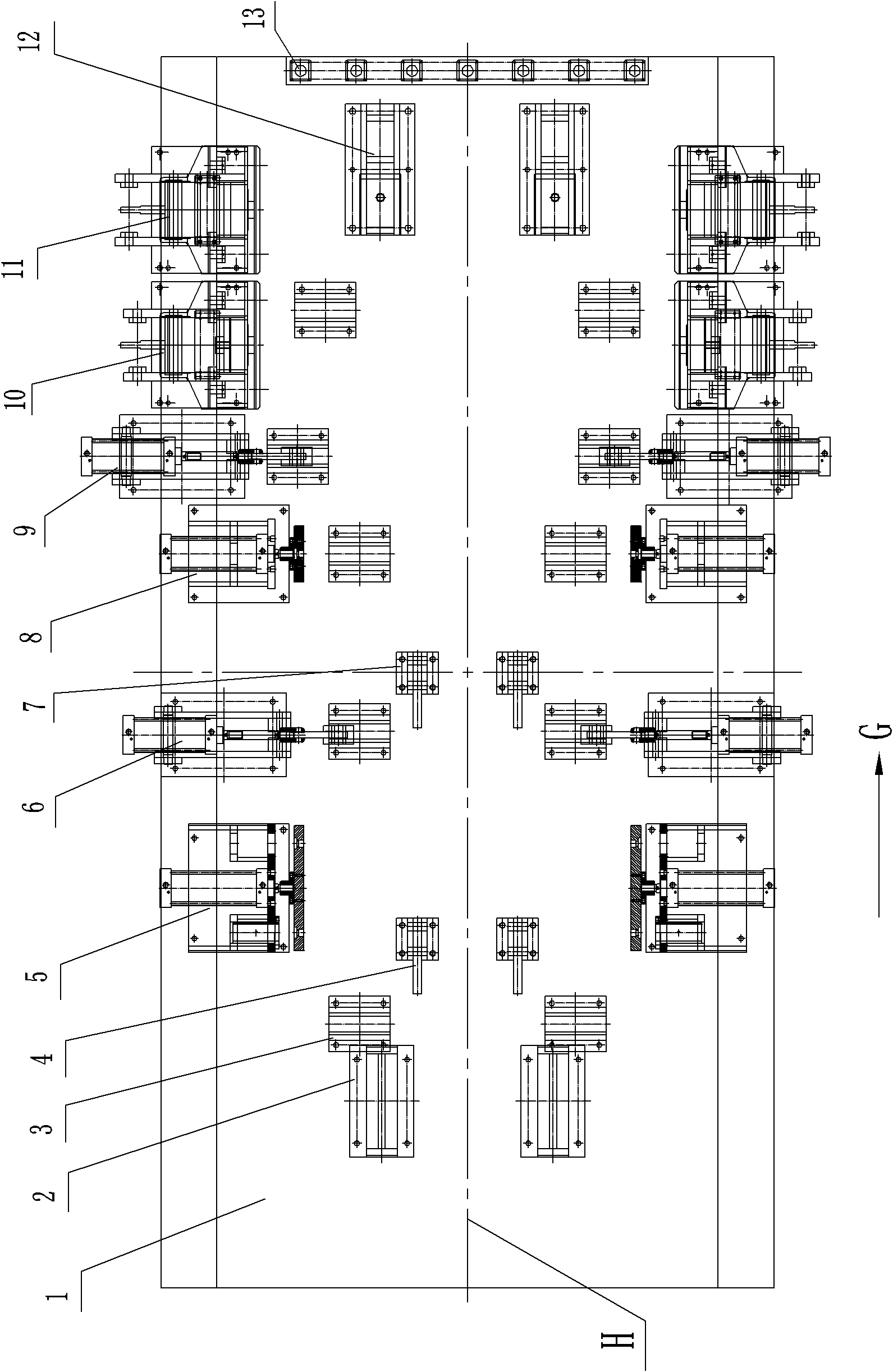

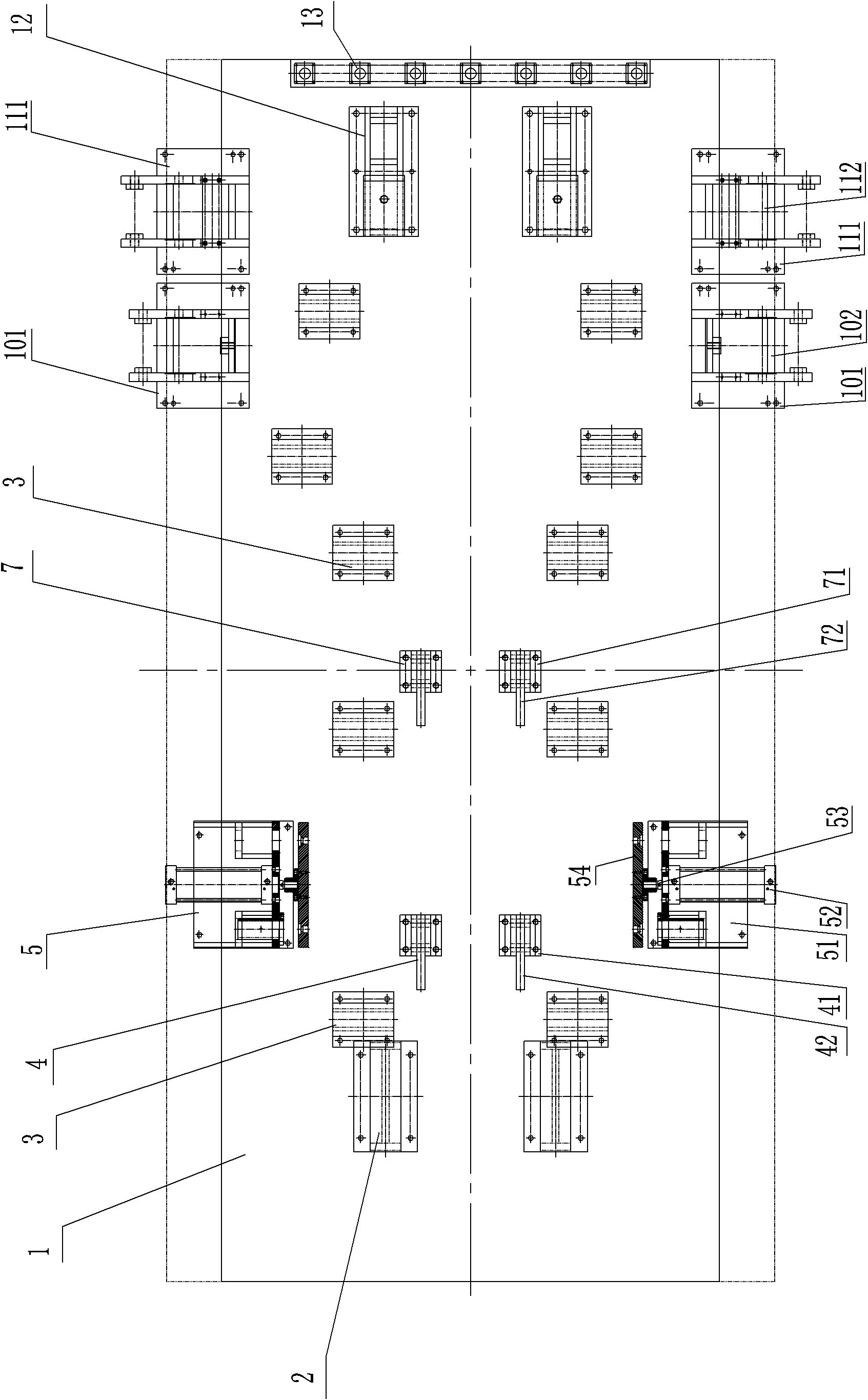

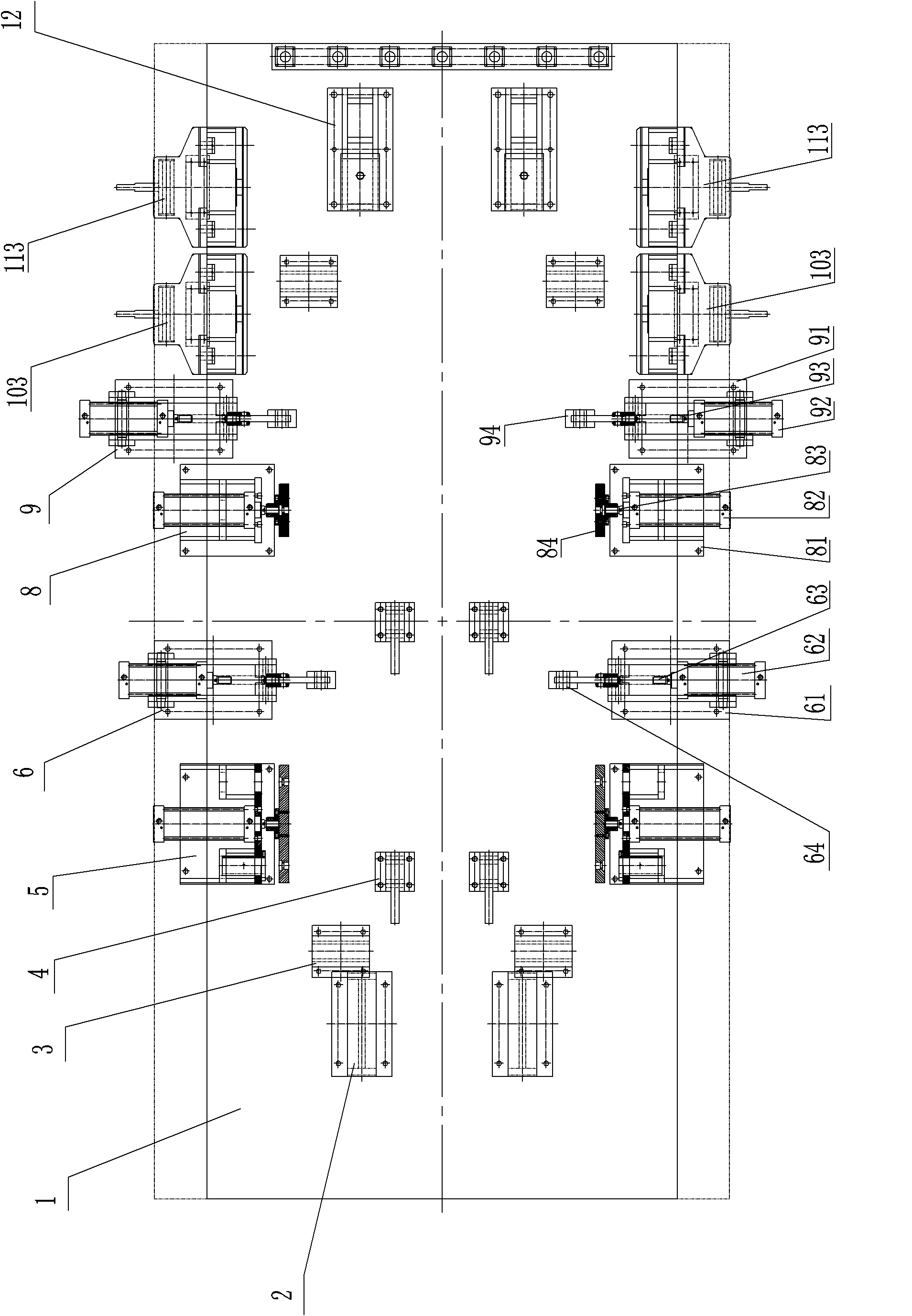

[0033] Such as Figure 1 to Figure 11 As shown, the main platform of the present invention builds a pneumatic tooling assembly. The pneumatic tooling includes a base 1 and a base plate seat 3 fixedly connected to the base 1, a counterweight support seat 2, a rear positioning seat 5, and a rear floor press. Seat 6, middle side positioning seat 8, front floor pressing seat 9, oil cylinder positioning seat 10 on the side plate, oil cylinder positioning seat 11 under the side plate, rear connecting plate positioning seat 4 and middle connecting plate positioning seat 7. figure 1 The direction indicated by the middle arrow G is the forward direction, and the direction opposite to the arrow G is the backward direction.

[0034] Base plate pedestals 3 are symmetrically arranged on both sides of base 1. Base plate pedestals 3 are used to support the main platform base plate A to ensure the flatness of the main platform base plate A. Since the base 1 is large, it is difficult to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com