Cage and method for closing closure gap by combining cage with filler

A filling and cage technology, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of high flow velocity, large tidal capacity, and increased investment in dikes at the mouth of the mouth, so as to reduce the width of the mouth of the mouth, save investment, shorten the The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 of the cage body: trapezoidal section, steel structure skeleton

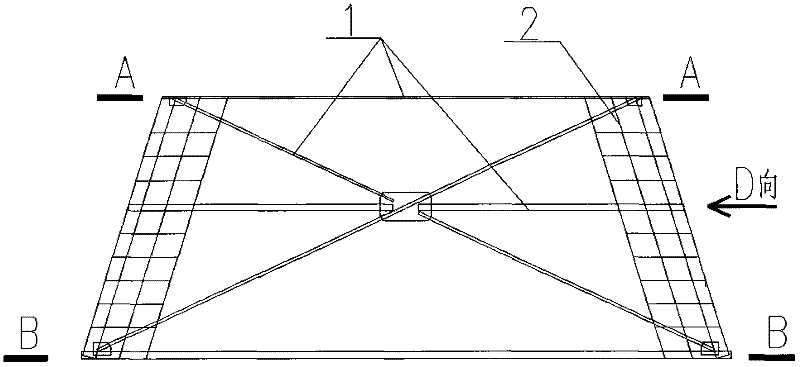

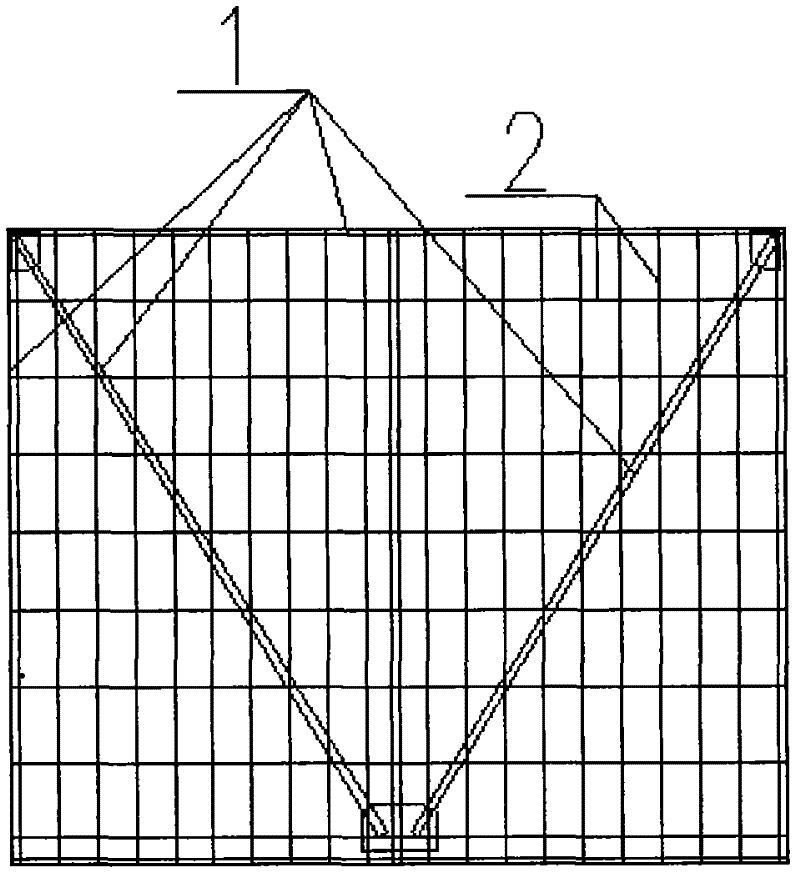

[0044] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , the cage body 3 is a space hexahedron cage structure, which is formed by connecting the space frame and the planar network structure 2, and the space frame is formed by connecting the planar truss or planar rigid frame 1 on the horizontal side, the longitudinal side, the bottom and the top, and the longitudinal direction can be set as required The planar truss or planar rigid frame of the diaphragm1.

[0045] In the height direction of the Longkou 5, the height of the cage body 3 is determined according to the elevation of the bottom of the installation and the interception elevation, generally 3m to 30m; in the transverse direction of the Longkou 5, the cage body 3 is trapezoidal, that is, the water facing surface on both sides of the horizontal direction adopts a slope type, The slope is 1∶0.2~1∶1.5, generally ...

Embodiment 2

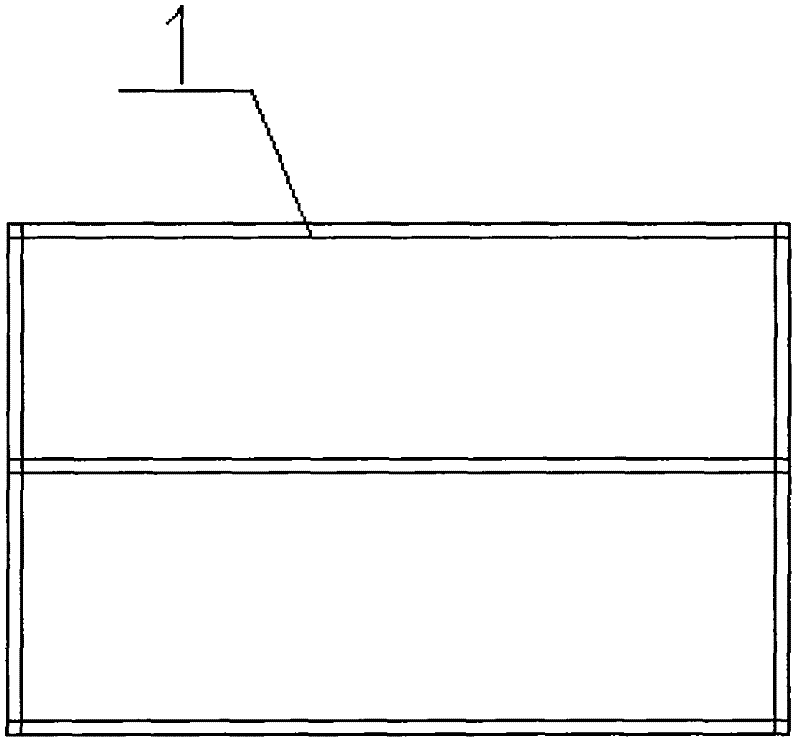

[0049] Cage embodiment two: rectangular section, steel structure skeleton

[0050] see Figure 7 , in the transverse direction of Longkou 5, the cage body 3 is rectangular, that is, the water-facing surfaces on both lateral sides are upright, and the width is generally 3m to 30m, which is determined by the overall stability calculation of the cage body according to the design conditions, and the rest are the same as the cage body embodiment 1. .

[0051] The actual size of a cage: In the transverse direction of Longkou 5, the cage 3 is rectangular, the upper and lower bottoms are 15m wide, the height is 8.9m, and the length of a single cage 3 is 10m. The plane truss or plane rigid frame 1 of the cage body 3 is formed by combined welding of section steel and flat steel, the plane mesh structure 2 adopts steel mesh, and the weight of a single cage body 3 is 28 tons.

Embodiment 3

[0052] Cage Example 3: Trapezoidal Section, Reinforced Concrete Skeleton

[0053] see Figure 8 , Figure 9 , Figure 10 The planar truss or planar rigid frame 1 is a reinforced concrete structure, and the planar mesh structure 2 adopts one or more combinations of steel mesh, steel mesh, steel mesh, and nylon mesh, and the rest are the same as the cage body embodiment one.

[0054] Embodiment 1 of the method of closure and closure of the dragon mouth using cages combined with fillers

[0055] see Figure 11 , Figure 12 , the first step of closing and closing the dragon, on the bottom protection structure 7 of the dragon mouth in the enclosing area 6, place the main structure of the closing and closing the dragon mouth - the cage body 3, the details are as follows: the width of a certain dragon mouth 5 is 800m, and the bottom protection structure of the dragon mouth in the enclosing area 6 7, continuously place cages 3 along the longitudinal direction of the dragon mouth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com