Rust preventive oil and preparation method thereof

A technology of anti-rust oil and composite anti-rust agent, which is applied in the petroleum industry, additives, lubricating compositions, etc., and can solve the problems of poor anti-rust performance and short anti-rust time of anti-rust oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

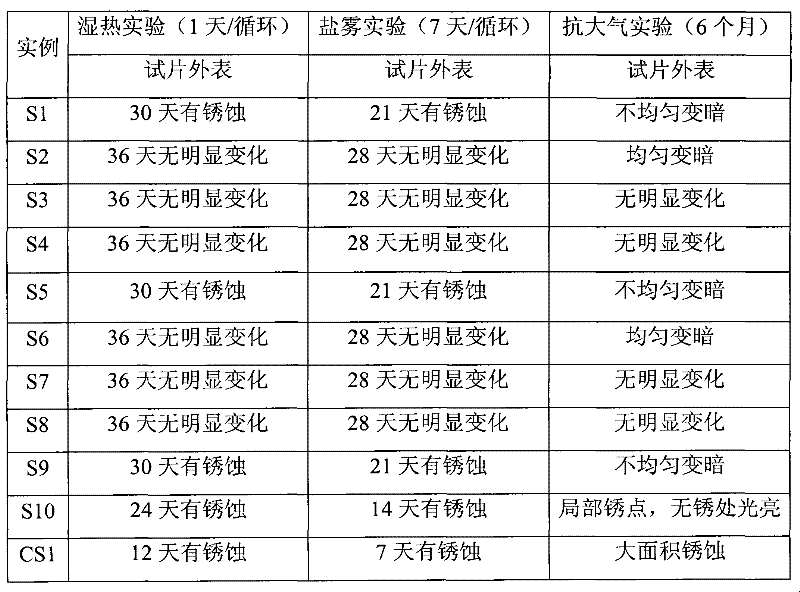

Examples

preparation example Construction

[0014] The present invention also provides a preparation method of anti-rust oil. The method is to put the base oil into the reaction kettle, then add the compound anti-rust agent, heat and stir until dehydration, and then filter to obtain the anti-rust oil, wherein the compound anti-rust agent The antirust agent is rare earth-β-diketone complex and barium petroleum sulfonate, sodium petroleum sulfonate, calcium petroleum sulfonate, barium dinonyl naphthalene sulfonate, barium heavy alkylbenzene sulfonate, non-barium type heavy alkyl A mixture of at least one of benzene sulfonate, magnesium lanolin soap, aluminum lanolin soap, aluminum stearate, barium oxide soap, and zinc naphthenate. During the mixing process of base oil and anti-rust agent in the reactor, polycondensation dehydration will be carried out, usually at 100°C-120°C, complete dehydration can be achieved, so as to achieve long-term anti-rust effect.

[0015] According to the preparation method of anti-rust oil pro...

Embodiment 1

[0024] Put 90 grams of solvent gasoline into the reaction kettle, stir, heat up to 75°C, then add 4 grams of lanthanum acetylacetonate, 1 gram of barium petroleum sulfonate, heat and stir to 100°C for dehydration, cool to 60°C, add 2 grams of benzotri Azole, 3 grams of industrial lanolin is fully stirred, and then filtered through a 500-mesh filter to obtain anti-rust oil.

[0025] The tinplate is directly immersed in the antirust oil obtained above for 3 minutes, and the tinplate is continuously vibrated. Then take it out and let it dry naturally.

Embodiment 2

[0027] Put 85 grams of solvent gasoline into the reaction kettle, stir, heat up to 75°C, then add 5 grams of europium acetylacetonate, 5 grams of barium petroleum sulfonate, heat and stir to 120°C for dehydration, then cool to 60°C and add 2 grams of benzotri After nitrogen azoles, 3 grams of dodecenylsuccinic acid are fully stirred, and then filtered through a 600-mesh filter, the anti-rust oil composition is obtained.

[0028] Dip the high-carbon steel directly into the above-mentioned anti-rust oil for 3 minutes, and vibrate the high-carbon steel continuously. Then take it out and let it dry naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com