Vehicle wheel

A wheel and rim technology, applied in the direction of wheels, spoked wheels, rims, etc., can solve problems such as cost increase, and achieve the effect of suppressing stress concentration, ensuring rigidity, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

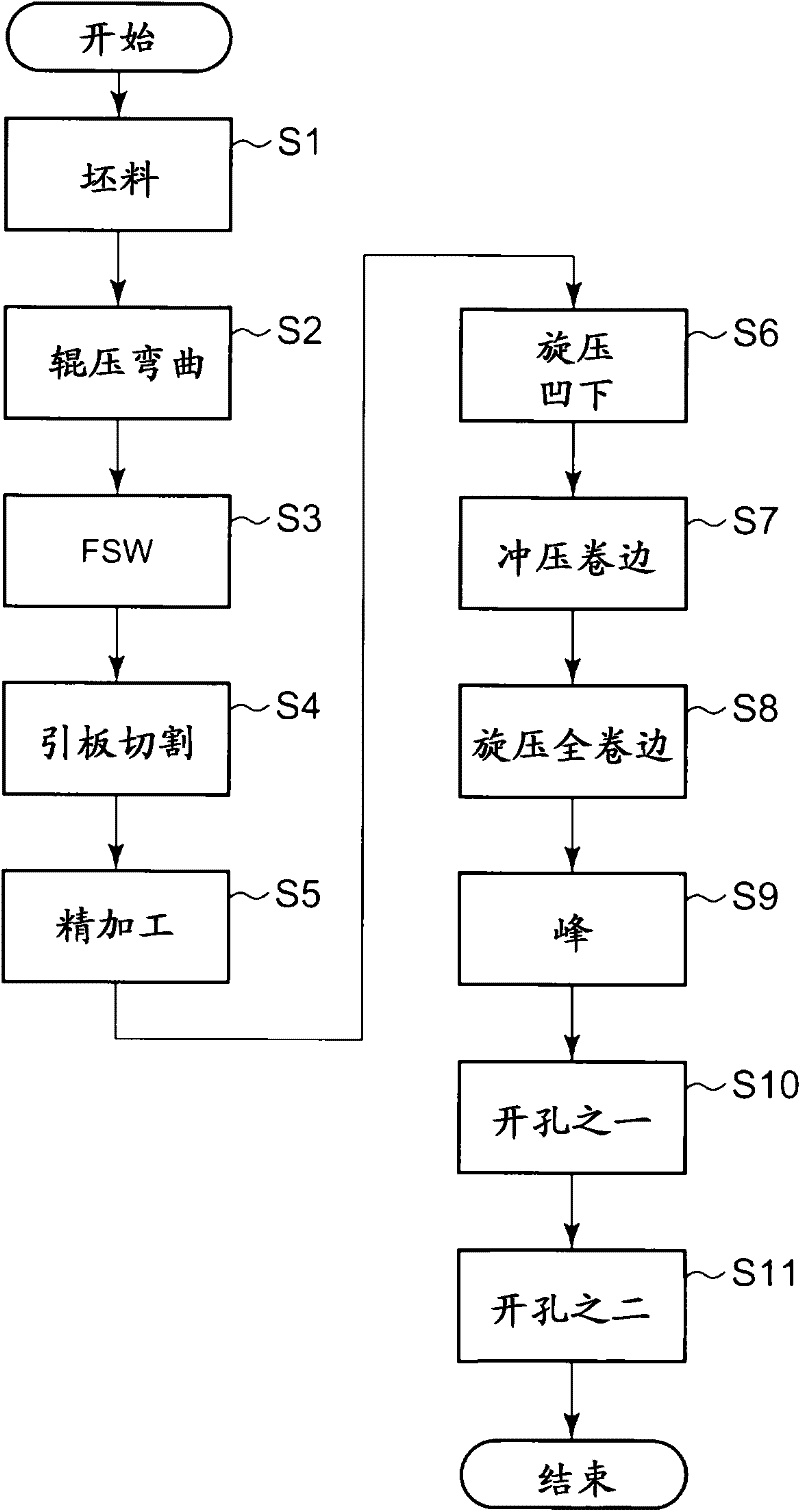

Method used

Image

Examples

Embodiment Construction

[0061] Embodiments of the present invention will be described below with reference to the drawings.

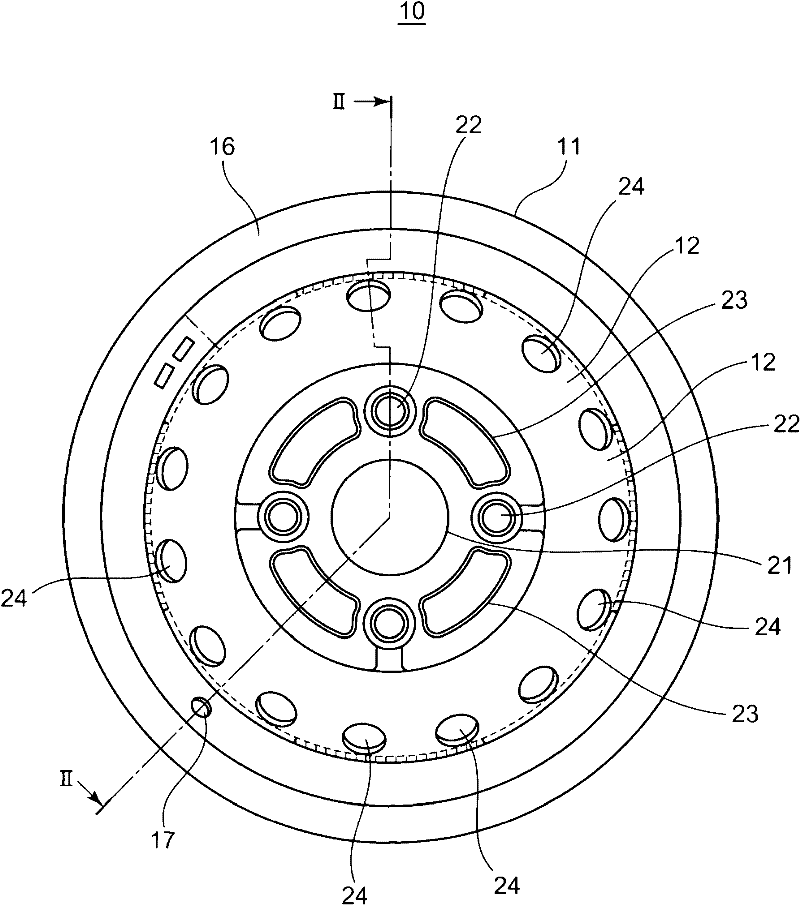

[0062] figure 1 It is an external view of the wheel of the embodiment.

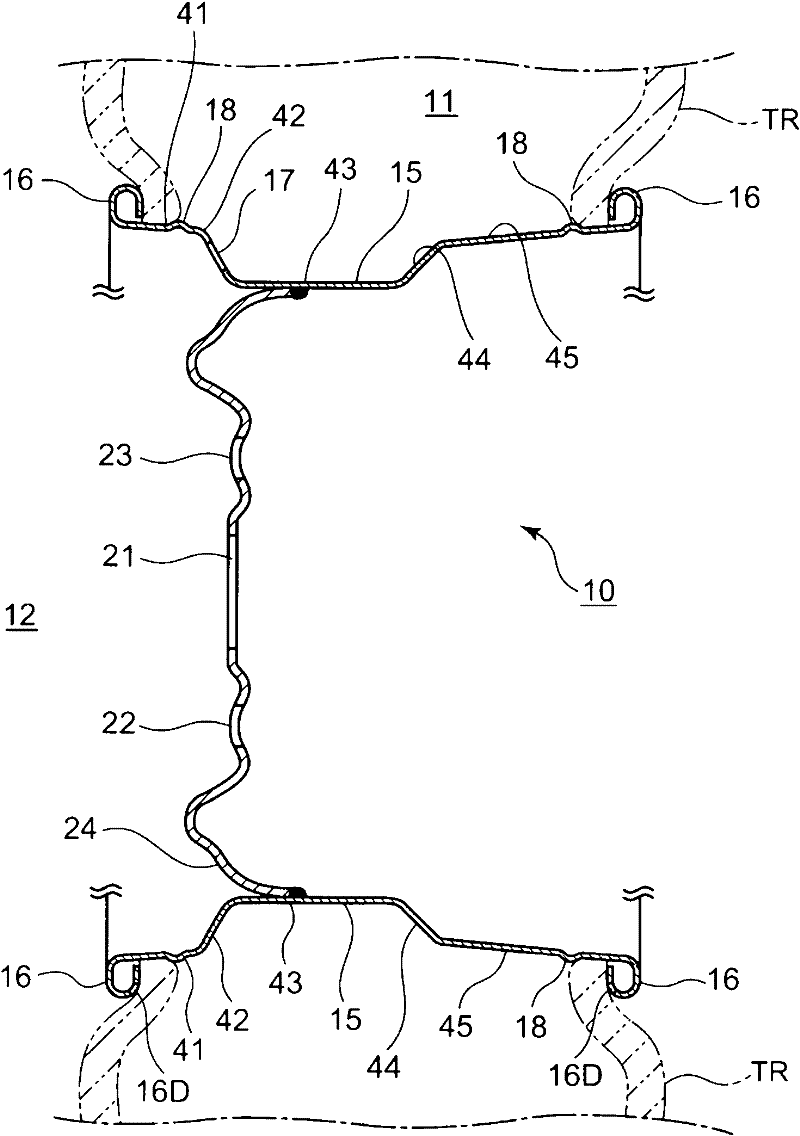

[0063] in addition, figure 2 for along figure 1 Sectional end view of the wheel II-II line.

[0064] The wheel 10 generally includes a substantially cylindrical rim portion 11 and a substantially disk-shaped disc portion 12 joined to the rim portion 11 .

[0065] rim part 11 such as figure 2 As shown, there is a rim body portion (recessed portion) 15 formed by shrinking the peripheral surface of the rim portion 11, and rims formed along the peripheral surface of the rim portion 11 at both ends of the rim portion 11, respectively. The flange portion 16, the valve hole 17 through which a valve (not shown) is inserted when the tire TR is mounted, and the peak portion 18 for making it difficult to disengage when the air pressure of the tire TR drops.

[0066] The wheel disc portion 12 has a hub hole 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com