Preparation method of continuous long bulked polytetrafluoroethylene panel

A polytetrafluoroethylene and polytetrafluoroethylene film technology, which is applied in the field of plastic processing, can solve problems such as low efficiency, length and width limitations, and achieve the effect of improving production efficiency and simplifying the lamination process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

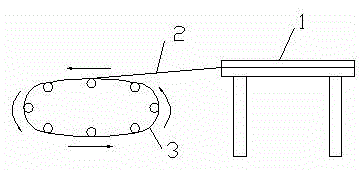

[0017] (1) The dispersed polytetrafluoroethylene resin is prepared into a calendered film by a paste molding method, and the expanded polytetrafluoroethylene film 2 is obtained through biaxial stretching. The thickness of the film is 0.05 mm, and it is directly coated on the surrounding steel belt 3 from the biaxial stretching machine 1. The surrounding steel belt 3 is 30 m long, 900 mm wide, and 0.2 mm thick. Adjust the rotation speed of the surrounding steel belt 3 to keep consistent with the forward speed of the bidirectional stretching machine 1, and the speed is 5 m / min. The steel belt 3 makes a circular motion to wrap the polytetrafluoroethylene film around the stack, a total of 30 laps, and fix the polytetrafluoroethylene film on the steel belt 3 after the wrapping is completed.

[0018] (2) Put the steel strip 3 coated with polytetrafluoroethylene film obtained in step (1) into a sintering furnace, heat it to 385° C. and keep it for 8 hours, turn off the electric heati...

Embodiment 2

[0021] (1) Dispersed polytetrafluoroethylene resin is prepared into a calendered film by a paste molding method, and an expanded polytetrafluoroethylene film is obtained through biaxial stretching. The thickness of the film is 0.1 mm, and it is directly coated on the surrounding steel belt 3 from the biaxial stretching machine 1. The surrounding steel belt 3 is 30 m long, 900 mm wide, and 0.2 mm thick. Adjust the rotation speed of the surrounding steel belt 3 to keep consistent with the forward speed of the bidirectional stretching machine 1, and the speed is 5 m / min. The steel belt 3 makes a circular movement to wrap the polytetrafluoroethylene film around the stack, a total of 40 laps, and fix the polytetrafluoroethylene film on the steel belt after the wrapping is completed.

[0022] (2) Put the steel strip coated with polytetrafluoroethylene film obtained in step (1) into a sintering furnace, heat it to 385° C. for 12 hours, turn off the electric heating and freely cool to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com