Punching tool

A technology of driving tools and driving parts, which is applied in the direction of nailing tools, manufacturing tools, packaging, etc., can solve the problems of hitting, poor driving, easy shaking, etc., and achieve the effect of improving durability and avoiding bad driving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

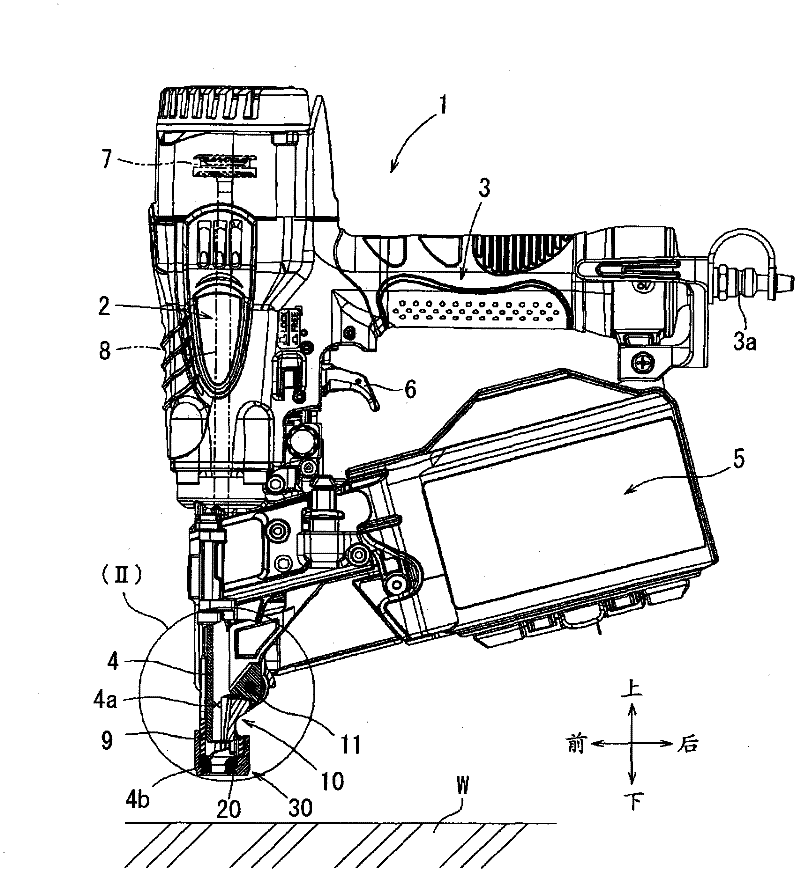

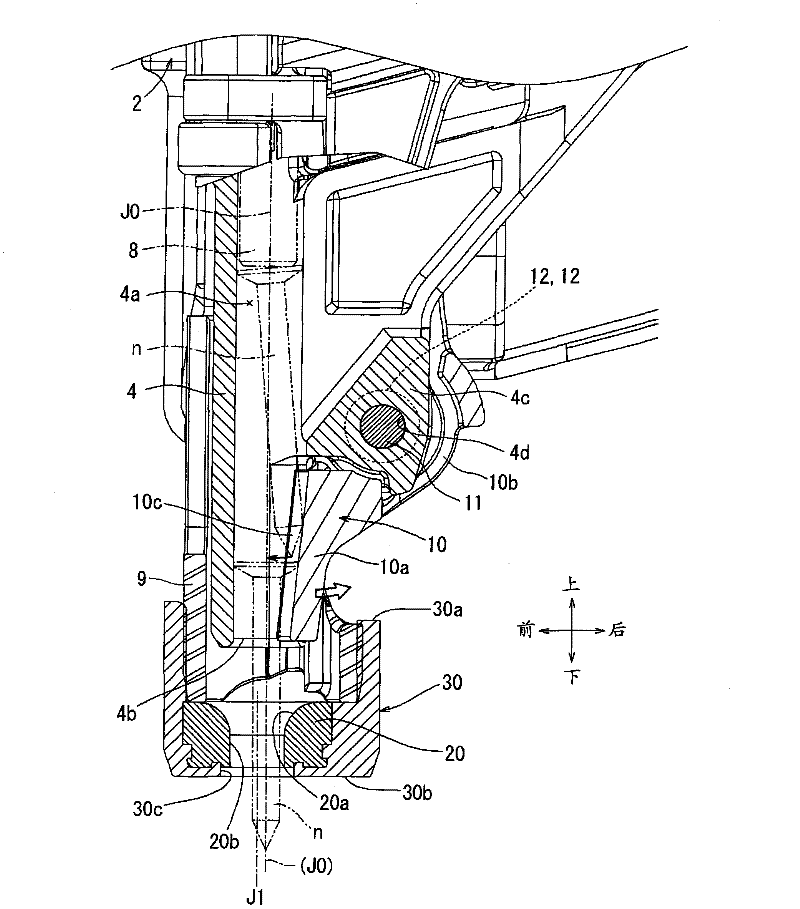

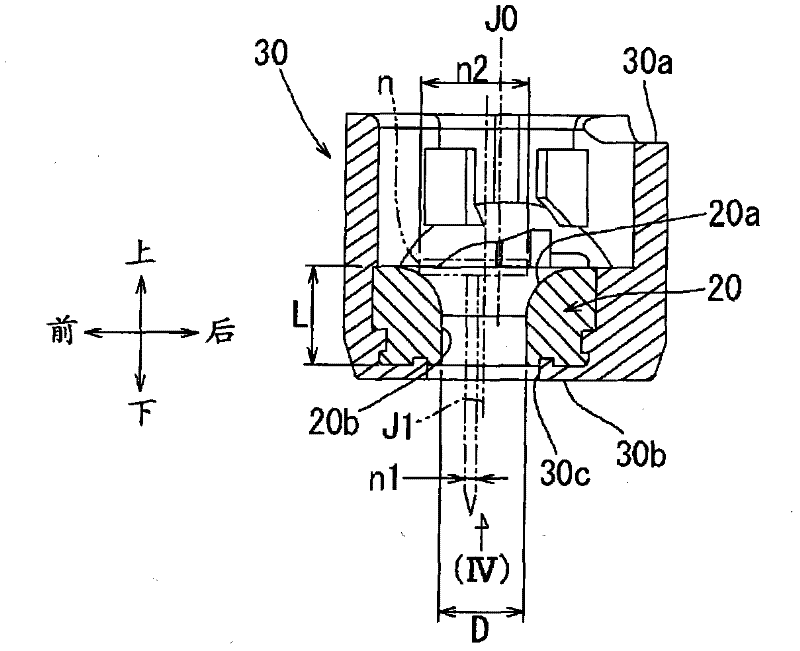

[0024] Next, refer to Figure 1 to Figure 7 Embodiments of the present invention will be described. figure 1 The whole of the driving tool 1 according to this embodiment is shown. The driving tool 1 of this embodiment is characterized by having a first restricting member for restricting the inclination of the driver n (inclination with respect to the moving direction of the driver 8 ) near the injection port to drive the driver n straightly. 10 and the second restricting member 20, other basic configurations of the driving tool do not need to be particularly changed, and thus detailed description thereof will be omitted. In addition, in this specification, regarding the up-down direction of a component or a structure, the driving direction of the driver n ( figure 1 The lower side) is the lower side, and the opposite direction is the upper side.

[0025] This driving tool 1 is a nailing machine driven by compressed air, and has: a body part 2 with a built-in piston 7; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com