Differential signal cable, cable assembly and multi-pair differential signal cable

A differential signal and cable assembly technology, applied in the direction of communication cables, electrical components, insulating cables, etc., can solve the problems of increased characteristic impedance, increased time lag, and difficulty in forming a storage drain line 34, etc., to achieve the goal of reducing the characteristic impedance mismatch, the effect of suppressing the increase in skew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Preferred embodiments of the present invention will be described below with reference to the drawings.

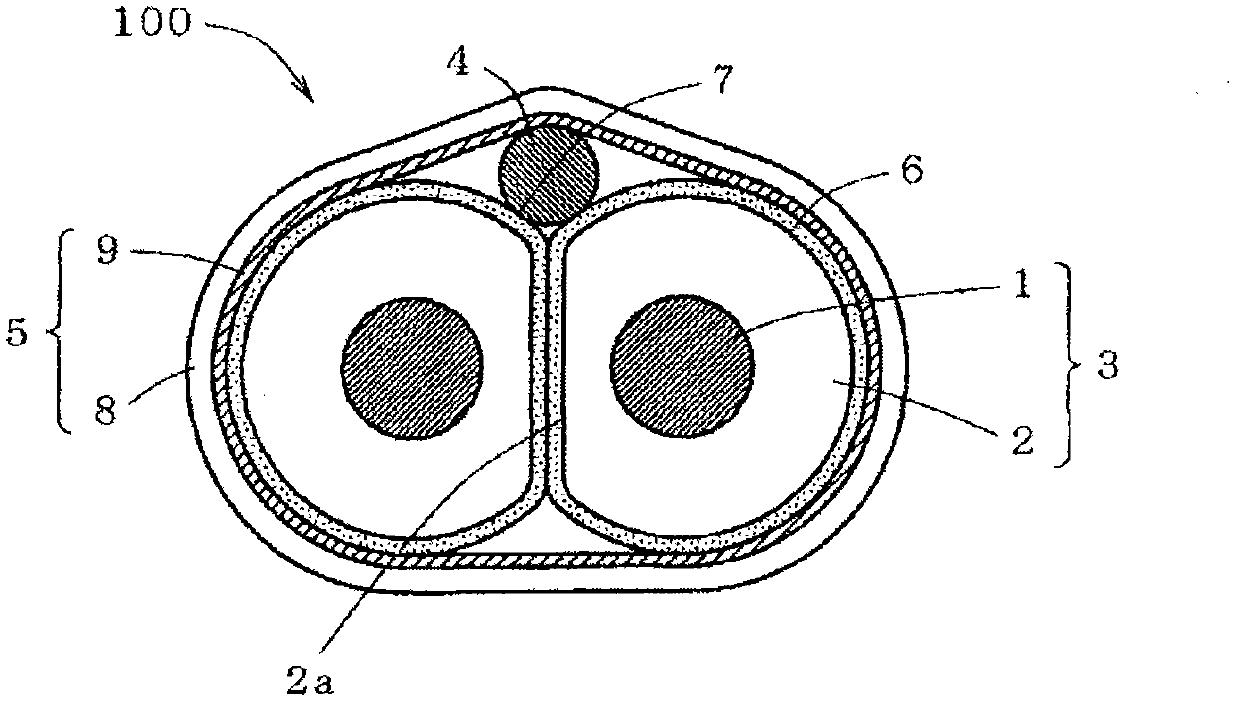

[0049] figure 1 It is a sectional view showing the differential signal cable of this embodiment.

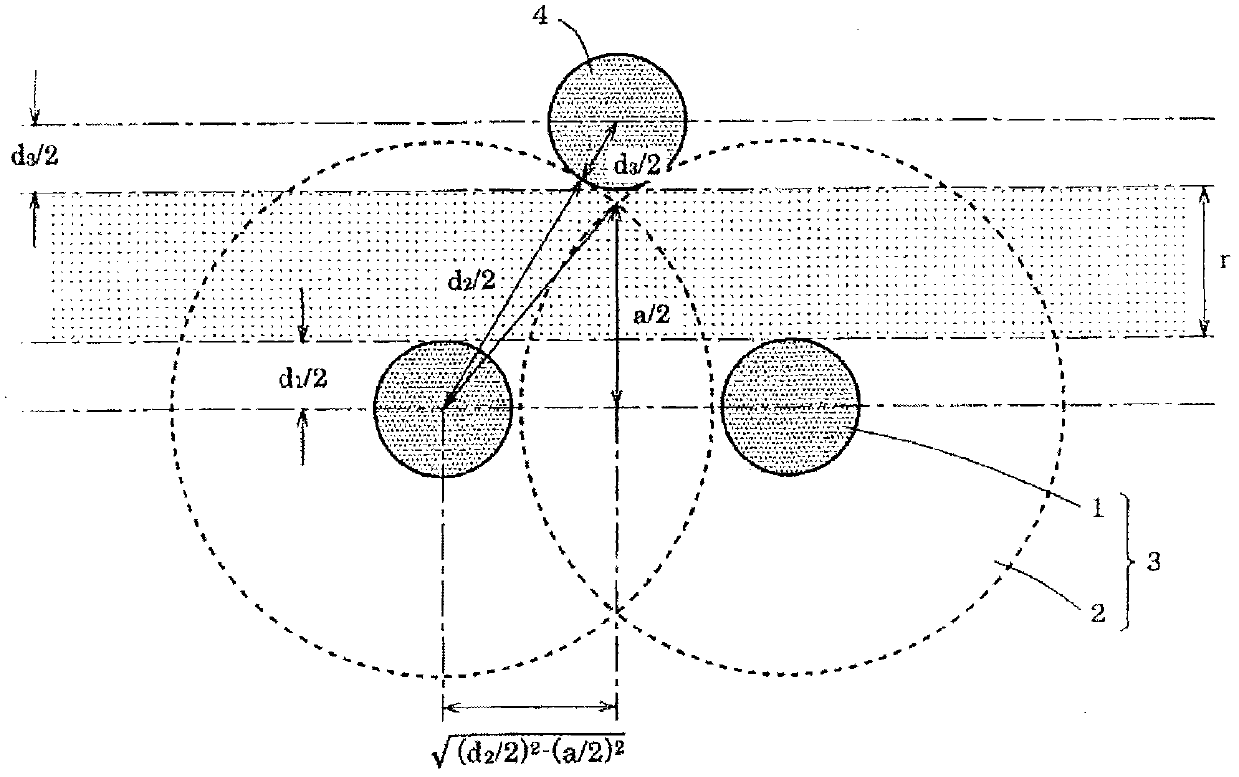

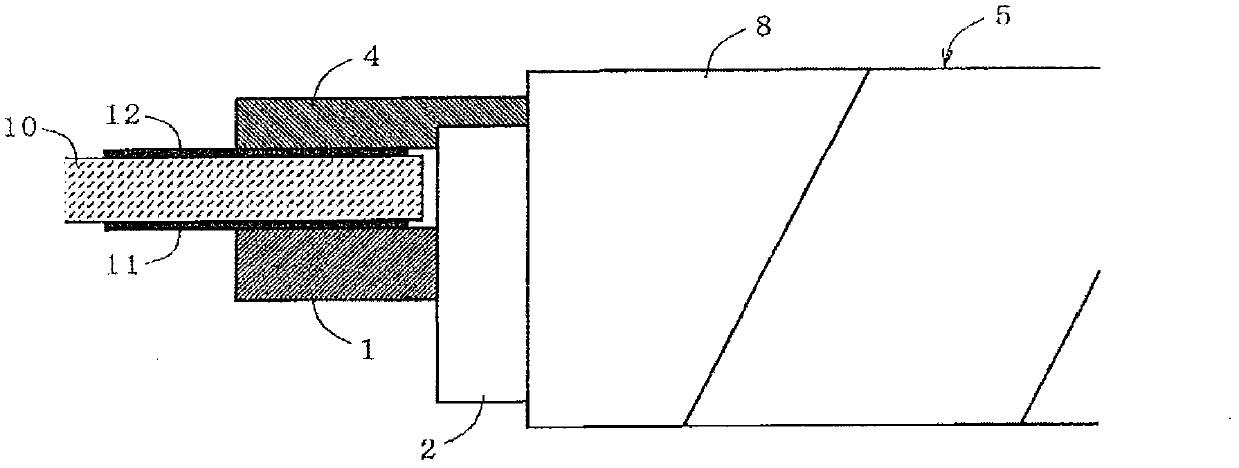

[0050] Such as figure 1 As shown, the differential signal cable 100 of the present embodiment is provided with: two insulated wires 3 that are made of a signal wire 1 and an insulator 2 covering the wire 1 and are arranged in parallel contact; The drain wire 4 is additionally arranged longitudinally in the recess 7 formed between the two insulated cables 3 ; the shielding tape 5 that wraps the two insulated wires 3 and the drain wire 4 together.

[0051] The wire 1 is covered with an insulator 2 supplied by an extruder, whereby an insulated wire 3 is formed.

[0052] As the lead wire 1 used for the insulated wire 3 , a good electrical conductor such as copper, or a single wire or a strand obtained by performing plating or the like on these good electrical conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com