Method and system for preventing condensation

An anti-condensation and condensation technology, applied in lighting and heating equipment, household refrigeration equipment, defrosting, etc., can solve the problems of large power loss, low work efficiency, uncertain heating power, etc., and achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

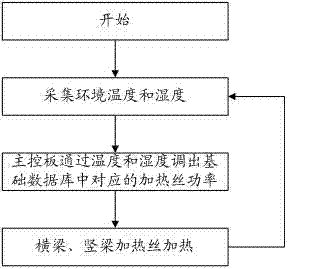

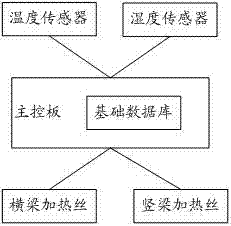

[0106] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0107] Basic data debugging test test method:

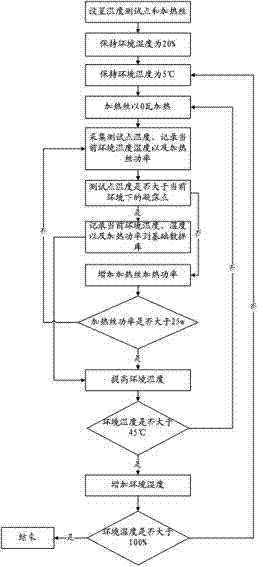

[0108] Such as figure 1 Shown:

[0109] 1. Test ambient temperature: control the temperature at 5-45°C respectively;

[0110] 2. Test environment humidity: control the humidity at 20%-100% respectively.

[0111] 3. Point layout: point distribution in each storage room (according to the American standard energy consumption test requirements), five points are equally spaced on the surface of the horizontal and vertical beams;

[0112] 4. Gear position: strong gear in the refrigerator / high gear in the freezer;

[0113] 5. Heating wire test conditions:

[0114] a. Vertical beam: 0W to 25W, increase by 1W each time (the power can also be increased in other increments); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com