System for monitoring and evaluating operational efficiency grade of bag type dust remover

A bag-type dust collector and bag-type dust collector technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problem of affecting the operation efficiency of the dust collector, the inability to intuitively observe the bag pollution and damage, and no work efficiency level issues such as monitoring and evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

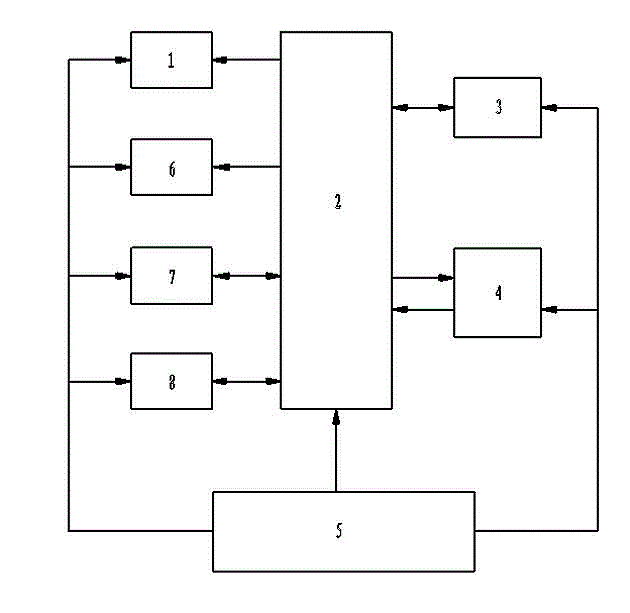

[0031] The monitoring and evaluation system of the operating efficiency level of the bag type dust collector, which includes: the operating efficiency level of the bag type dust collector

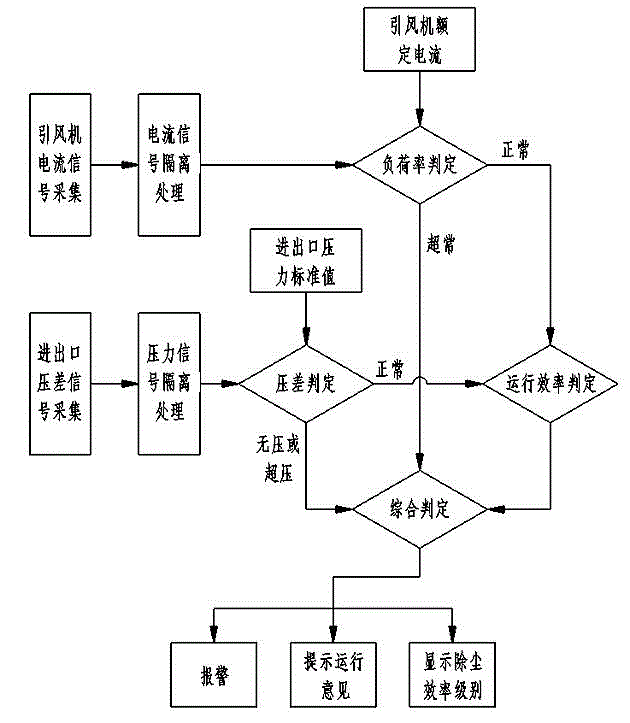

[0032] Automatic detection device and computer system, the automatic detection device is a monitoring device that can work independently, to realize automatic real-time measurement of the working current value of the induced draft fan and the pressure difference between the inlet and outlet of the bag filter when it is working, and communicate with the special computer system; through the computer The system communicates with the automatic monitoring device to complete the setting and data transmission of the automatic monitoring device; through the computer system, the collected data is stored, analyzed and evaluated in real time, and the evaluation results are output to realize the rapid evaluation of the operating efficiency level of the bag filter.

[0033] The evaluation method of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com