Shaft alignment and anti-corrosion liner for a disk gang

A disc bearing and disc technology, which is applied to shafts and bearings, rotating bearings, bearings, etc., can solve problems such as difficulty, bearing rust maintenance, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

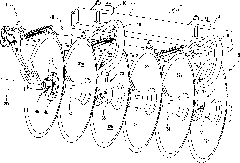

[0008] Refer to attached figure 1 , shows a portion of an agricultural disc 8 with a disc pack arrangement 10 . Said disc 8 comprises a disc frame 12 adapted to move over the ground in a forward advancing direction F until the ground breaks up clods and adds plant residues to the soil. The frame 12 extends generally transversely to the forward direction F and supports a plurality of spaced C-spring pack mounting bases 16 made of spring steel. The base 16 includes an upper end connected to the frame 12 by a mounting bracket 18 .

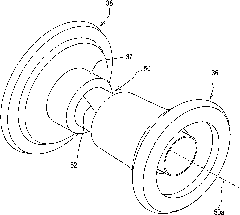

[0009] A disc pack bearing arrangement 20 having a bearing inner ring 20 a is connected by bolts 22 to a lower horizontally extending leg 26 of each base 16 . A disc pack bolt or shaft 30 having an axis 30a extends through the inner race 20a of the bearing assembly 20 and supports a plurality of transversely spaced disc blades 32, 32a and 32b having a central circular hole 32C which accommodates the Shaft 30 passes through. Spacer members 34, 36, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com