Dual-claw polar multi-phase excitation generator

A generator and double claw pole technology, applied in the shape/style/structure of winding conductors, etc., can solve the problems of low power, large relative surface area and high cost of generators for vehicle generators, and achieve small synchronous reactance and number of phases. The effect of many, low excitation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

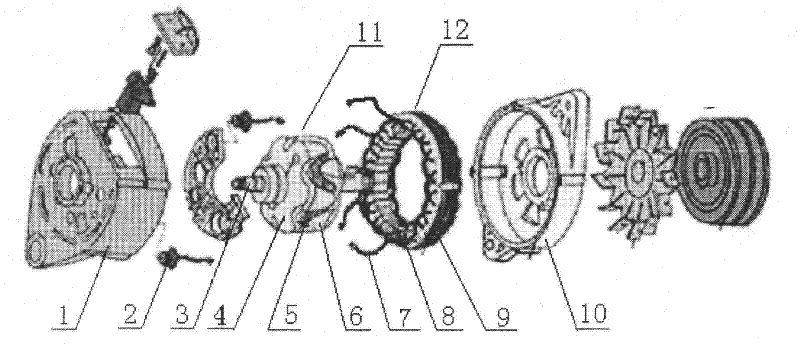

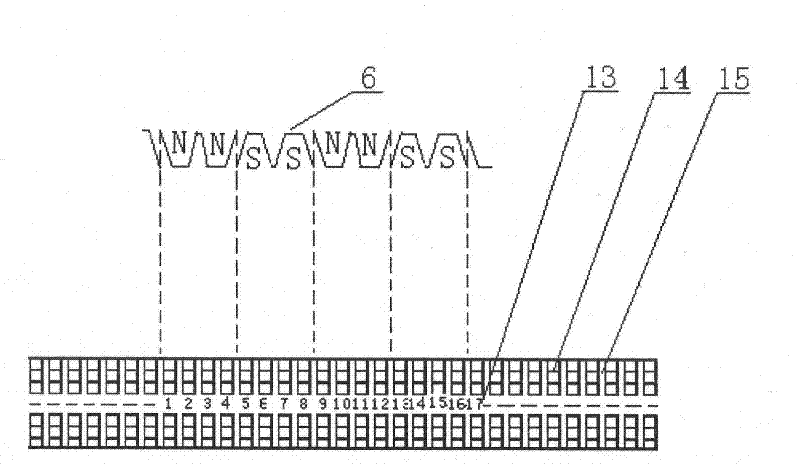

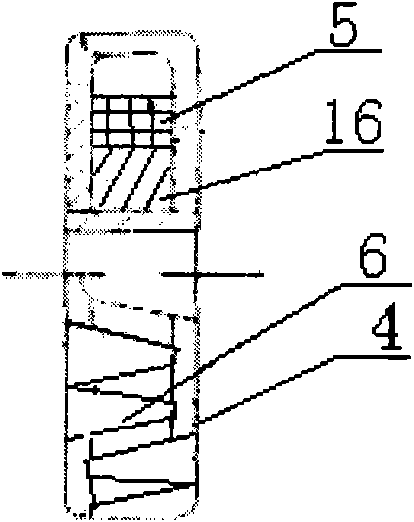

[0029] 1. Rear cover; 2. Diode; 3. Shaft; 4. Flange; 5. Excitation winding; 6. Claw pole; 7. Tail end of armature winding; 8. Armature winding; 9. Stator core ;10, front end cover; 11, rotor; 12, stator; 13, stator core pole number; 14, stator core pole; 15, stator core wire groove; 16, rotor core; 17, voltage stabilizer; 18 , Four-phase bridge rectifier; 19, permanent magnet rotor core; 20, cast bracket; 21, pole shoe; 22, non-magnetic screw; 23, permanent magnet.

[0030] Combine below figure 1 , figure 2 , image 3 , Figure 4 The present invention is described further:

[0031] The double-claw-pole multi-phase excitation generator comprises a front end cover 10, a rear end cover 1, a four-phase bridge rectifier 18, a voltage stabilizer 17, a rotating shaft 3, a stator composed of a stator core 9 and an armature winding 8, composed of The rotor consists of rotor core 16, claw pole 6, flange 4, and field winding 5; the first end of the armature winding 8 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com