Electromagnet with current separation channel

An electromagnet and sorting technology, applied in the field of electromagnets, can solve the problem of easy burnout of the coil, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

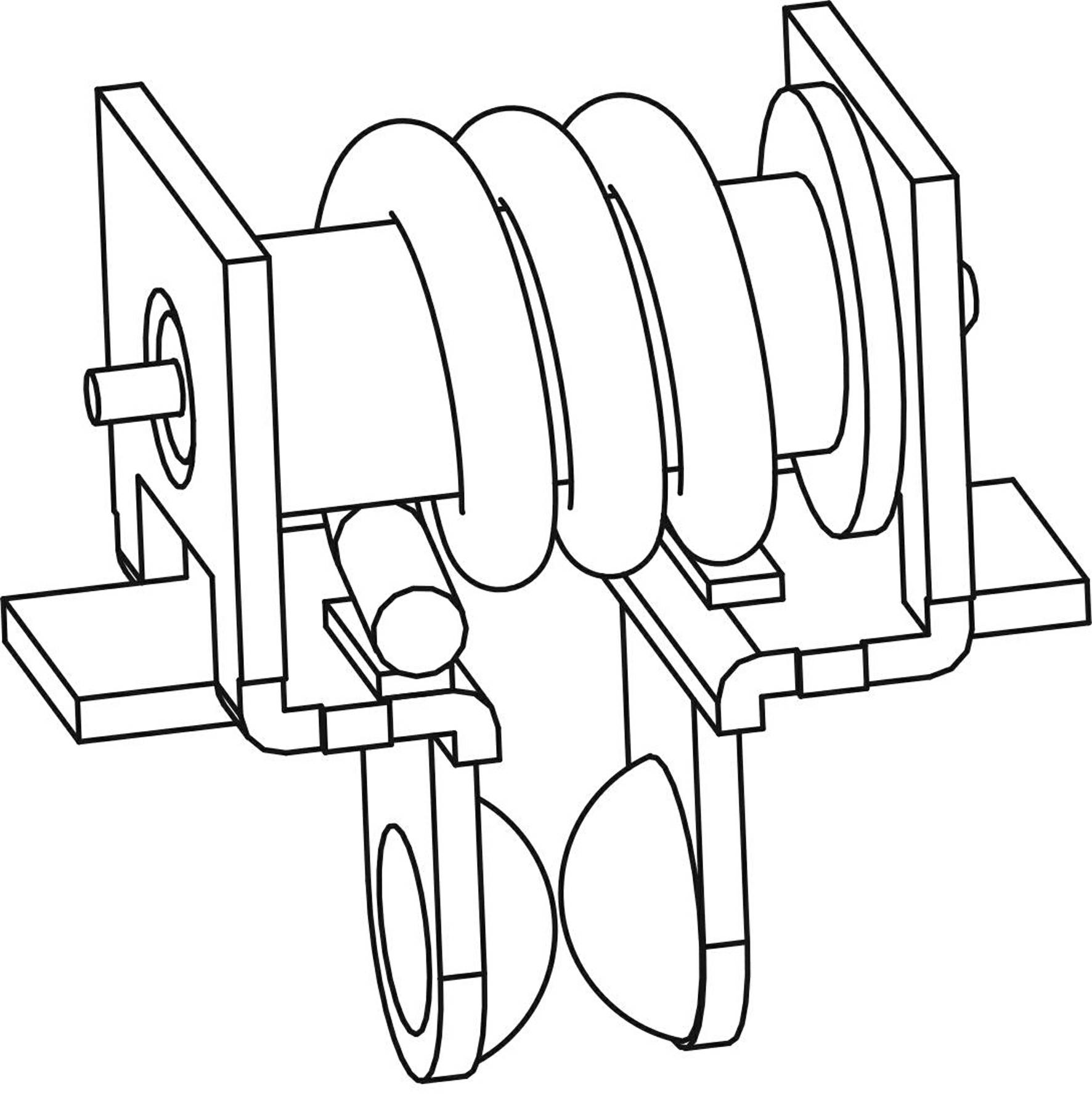

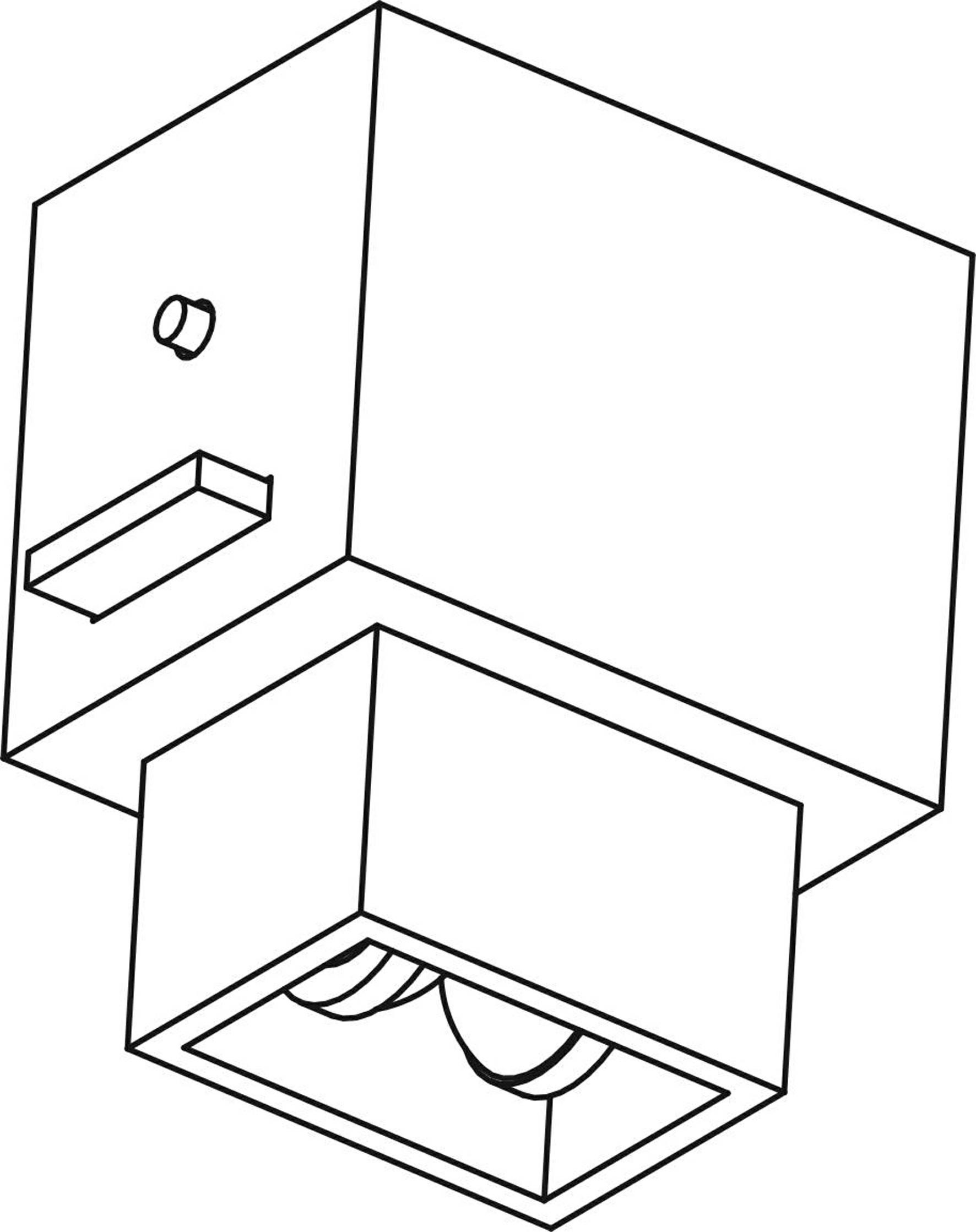

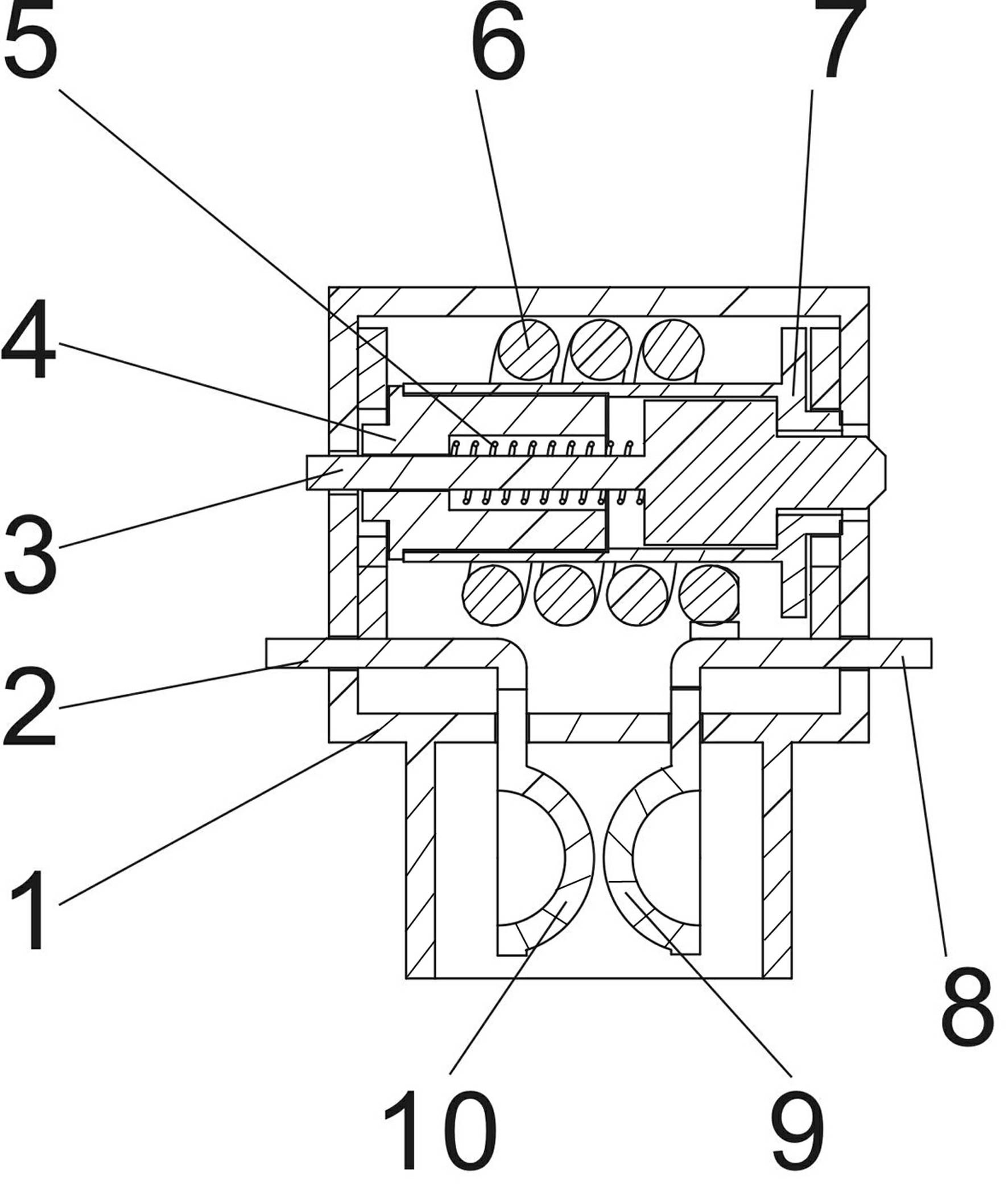

[0013] An electromagnet with a current sorting channel according to the present invention, such as figure 1 , 2 , 3, 4 shown, it comprises the electromagnet that is made up of moving iron core 3, static iron core 4, recovery spring 5, electromagnetic coil 6, a pair of hemispherical protruding parts facing each other in parallel at the two ends of electromagnetic coil 6 discharge electrode. image 3 Also marked with housing 1, left terminal 2, coil support 7, right terminal 8, right discharge electrode 9, left discharge electrode 10.

[0014] Figure 4 Among them, D is the moving iron core of the electromagnet, which can move along the direction of the arrow. L is the electromagnetic coil, A and B are the two ends of the coil channel, and S is the gap arrester. The power frequency current passes through A and reaches the terminal B through the electromagnetic coil L, and the moving iron core of the electromagnet moves quickly to achieve the purpose of driving. When the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com