Cut-and-fill three-dimensional simulation test device and method

A simulation test, three-dimensional technology, applied in mining devices, fillings, safety devices, etc., can solve the problems of limited simulation effect, inability to simulate, single function, etc., and achieve the effect of high practical value, simple structure, compact and reasonable effect

Active Publication Date: 2011-09-14

CHINA UNIV OF MINING & TECH

View PDF6 Cites 40 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing three-dimensional model test device can only simulate the mining of the working face, but cannot simulate the fully mechanized mining and filling process of coal seam mining and goaf filling simultaneously

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

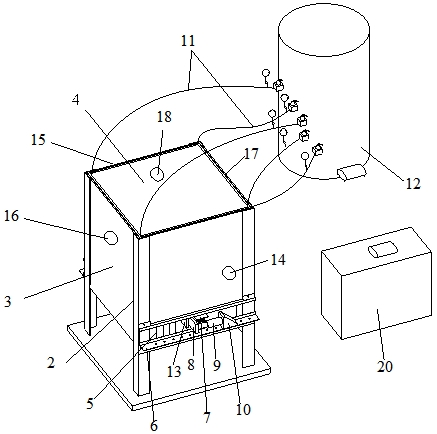

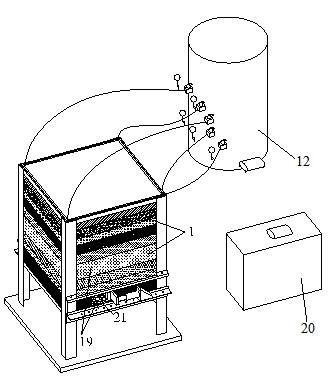

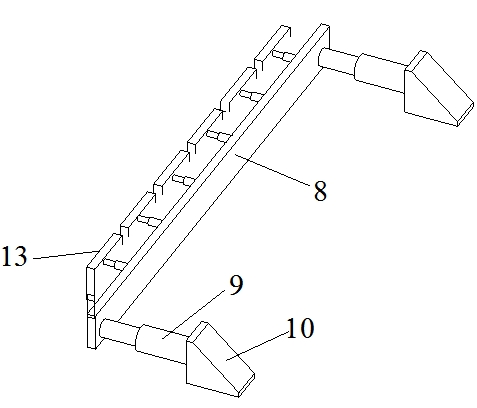

The invention discloses a cut-and-fill three-dimensional simulation test device and method. The device mainly comprises a box-shaped table type test model frame, a cut-and-fill simulation system, an equivalent loading system and a wireless information acquisition system. The cut-and-fill three-dimensional simulation test device can truly reproduce the concrete process of simulating the fully-mechanized working surface mining, goaf filling, filler material compacting and the like in real conditions; and the wireless information acquisition system can monitor the three-dimensional change conditions of pressure and displacement in goaf filler and overlying strata on a coal face in the filling process in real time, and truly reflect the cut-and-fill field conditions through computer image simulation. The cut-and-fill three-dimensional simulation test device has simple structure and is convenient to operate; and the test method is stable and reliable, and has high practical values.

Description

technical field [0001] The invention relates to a similar material simulation test device and method, in particular to a filling mining three-dimensional simulation test device and method suitable for studying "three-down" filling mining rock formation movement characteristics and goaf filling strength in mining engineering. technical background [0002] As a country with coal as the main energy source, my country's rapid economic development requires a rapid increase in coal production. However, many mining areas are facing problems such as the depletion of resources, environmental damage, and the "three-down" coal pressure is too large to be mined. The gangue filling coal mining technology that uses the underground goaf to dispose of gangue can not only recover the "three down" coal pressure, reduce the discharge of coal mine solid waste on the ground, liberate the mine's lifting capacity, but also reduce deep mining and subsidence disasters. One of the key technical appr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21F15/00E21F15/02E21F17/18

Inventor 马占国赵国贞张帆史向军肖亚宁黄志敏龚鹏耿敏敏孙凯范金泉潘银光朱发浩兰天

Owner CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com