Winding mode of elevator steel wire rope and elevator

A wire rope and elevator technology, which is applied in the field of elevators, elevators or elevators, and can solve problems such as the deterioration of elevator operation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

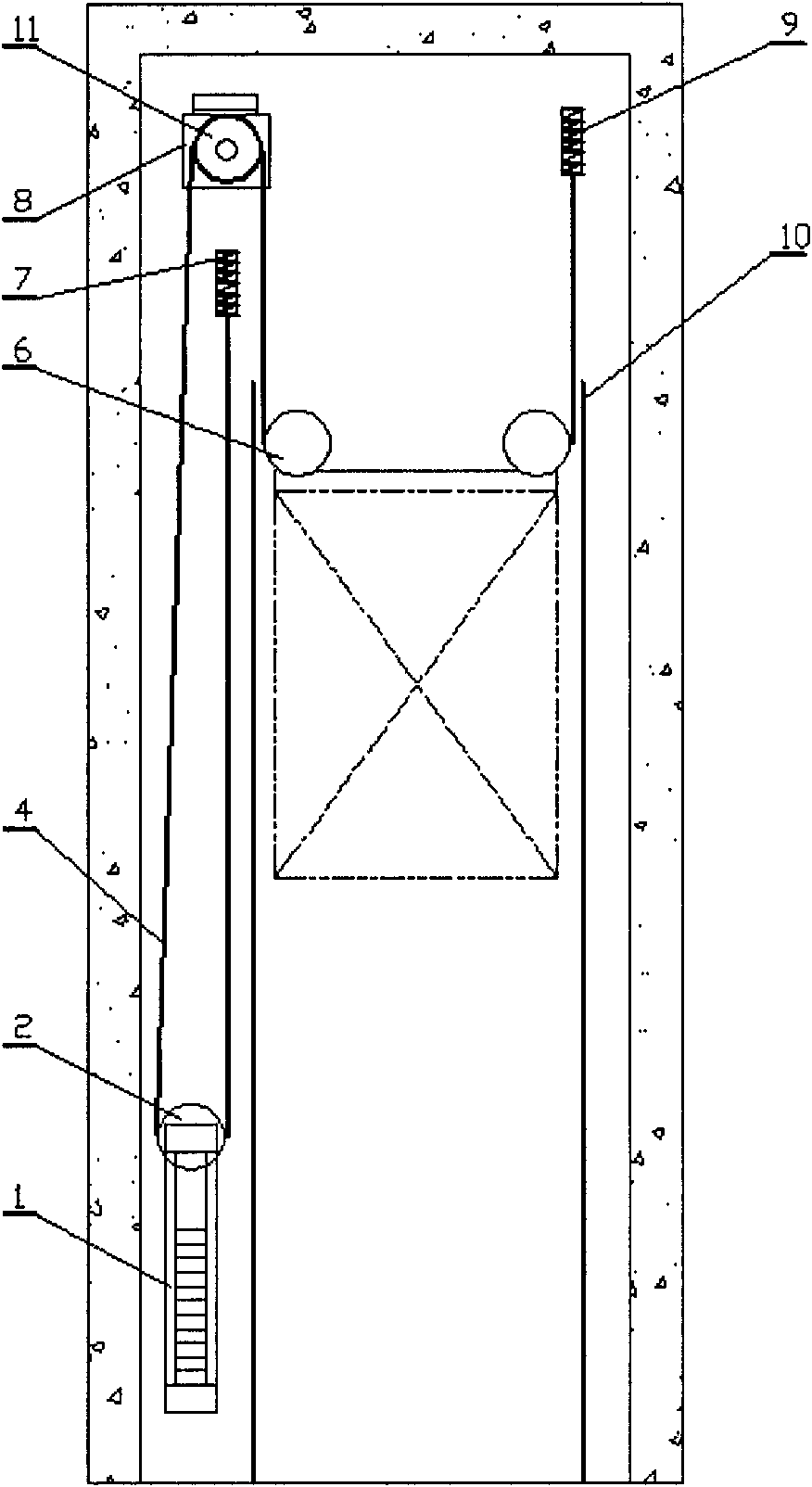

[0022] Attached below Figure 1-8 The specific technical contents and embodiments of the present invention are further elaborated.

[0023] attached figure 1 , 2 Indicates an embodiment of the new winding method of the elevator wire rope or steel belt provided by the present invention and the new arrangement method of the rope end combination in the whole elevator, which mainly includes the counterweight device 1 of the elevator, two rows of counterweight guide rails 3, the steel wire rope Or steel belt 4, car 5, two car top wheels 6, counterweight side rope end combination 7, traction machine 8, car side rope end combination 9, two rows of car guide rails 10, wherein the counterweight The device 1 includes a counterweight, a counterweight wheel 2 and a counterweight frame, and the counterweight wheel 2 is arranged on the upper part of the counterweight device 1. The traction machine 8 includes a traction wheel 11 and a traction machine body. The traction machine 8 Arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com