Method for reducing protein of cigar core leaves

A protein and cigar core technology, applied in the processing of tobacco, tobacco, application, etc., can solve the untargeted problem of cigar tobacco leaf protein content, not provided, and the quality of tobacco leaf raw materials has not been fundamentally improved, so as to improve the quality of the core Effects of leaf quality, reduction of bitterness and astringency, and reduction of irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Protease combination enzyme preparation: a combination enzyme preparation containing neutral protease and alkaline protease.

[0033] Divide the core leaves of the same place of origin and grade into two parts, one part is the control sample, and the other part is processed according to the following method.

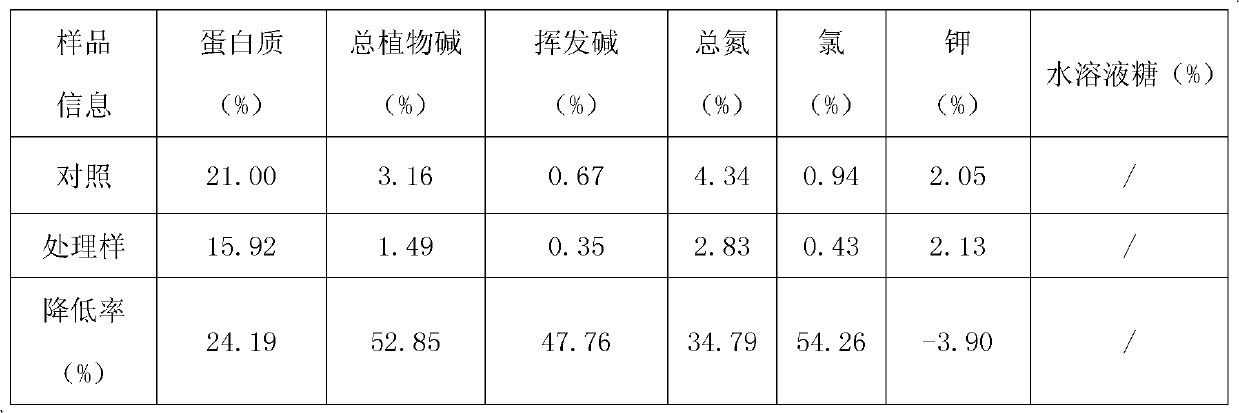

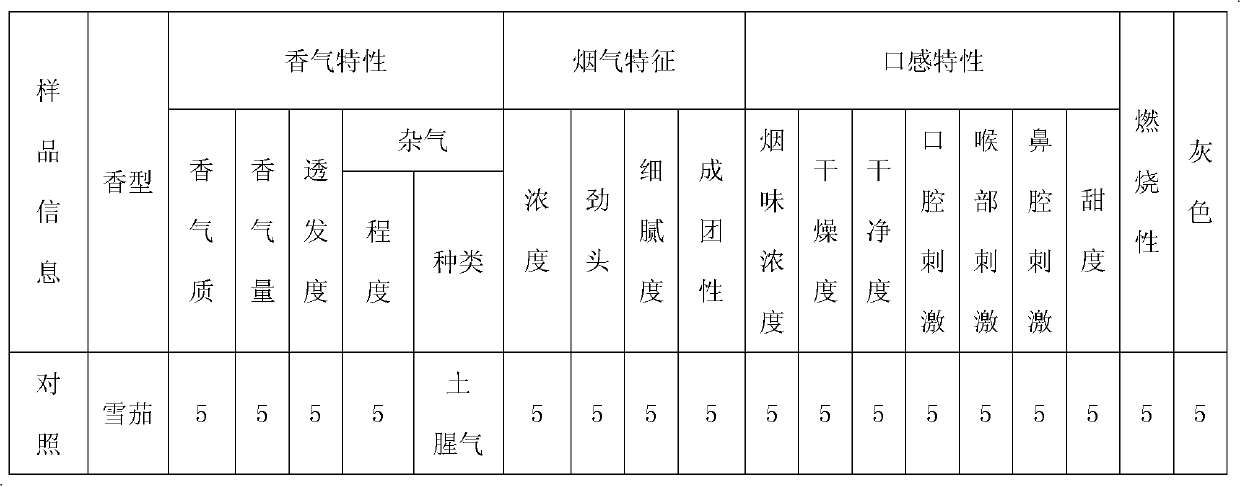

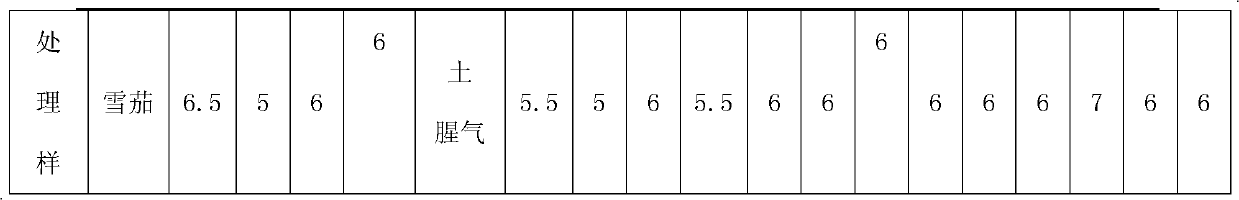

[0034] The combined enzyme preparation containing neutral protease and alkaline protease is dissolved in water to make enzyme liquid, and the mass fractions of neutral protease and alkaline protease in water are 2.5% and 0.5% respectively. Irrigate the core leaves with water to regain moisture, and the final moisture reaches 25%. The enzyme liquid is sprayed on the core leaves after resurgence, and the weight ratio of the two is 10:100. The artificial fermentation conditions of the core leaves after enzyme application are temperature 45° C., relative humidity 85%, and time 24 hours. Immediately after the end of the fermentation, the enzyme was cut off at 90° C. ...

Embodiment 2

[0036] Protease combination enzyme preparation: a combination enzyme preparation containing complex protease, neutral protease and alkaline protease.

[0037] Divide the core leaves of the same place of origin and grade into two parts, one part is the control sample, and the other part is processed according to the following method.

[0038] The combined enzyme preparation containing compound protease, neutral protease and alkaline protease is dissolved in water to make enzyme liquid, and the mass fractions of each protease in water are 0.3%, 1.8% and 0.4% respectively. Irrigate the core leaves with water to regain moisture, and the final moisture reaches 25%. The enzyme liquid is sprayed on the core leaves after resurgence, and the weight ratio of the two is 15:100. The artificial fermentation conditions of core leaves after enzyme application are temperature 45° C., relative humidity 85%, and time 12 hours. Immediately after the end of the fermentation, the cut-off of the ...

Embodiment 3

[0040] Protease combination enzyme preparation: a combination enzyme preparation containing complex protease, acid protease, neutral protease and alkaline protease.

[0041] Divide the core leaves of the same place of origin and grade into two parts, one part is the control sample, and the other part is processed according to the following method.

[0042] The combined enzyme preparation containing compound protease, acid protease, neutral protease and alkaline protease was dissolved in water to make enzyme liquid, and the mass fractions of each protease in water were 0.15%, 1.2%, 2.0% and 0.25%. Irrigate the core leaves with water to regain moisture, and the final moisture reaches 25%. The enzyme liquid is sprayed on the core leaves after resurgence, and the weight ratio of the two is 12:100. The condition of the artificial fermentation of the core leaf after enzyme application is temperature 42°C, relative humidity 80%, and time 48h. Immediately after the end of the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com