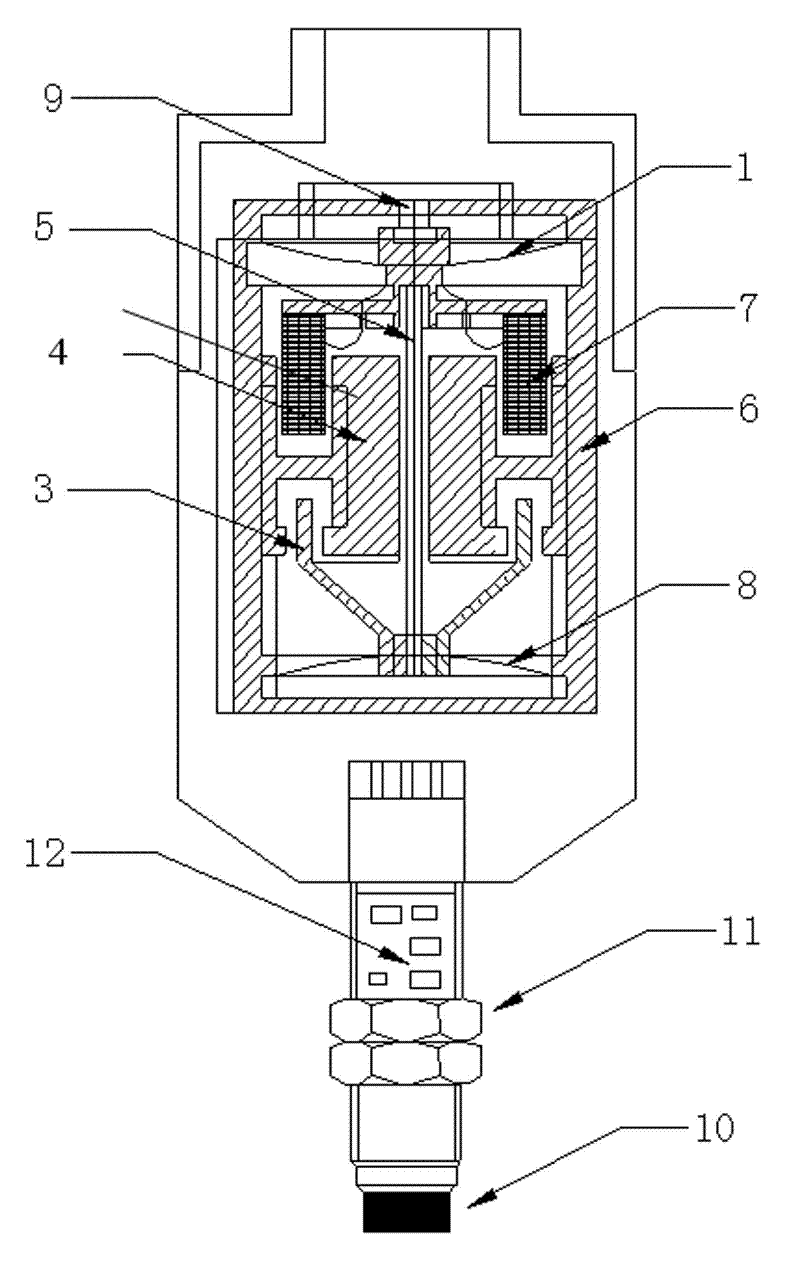

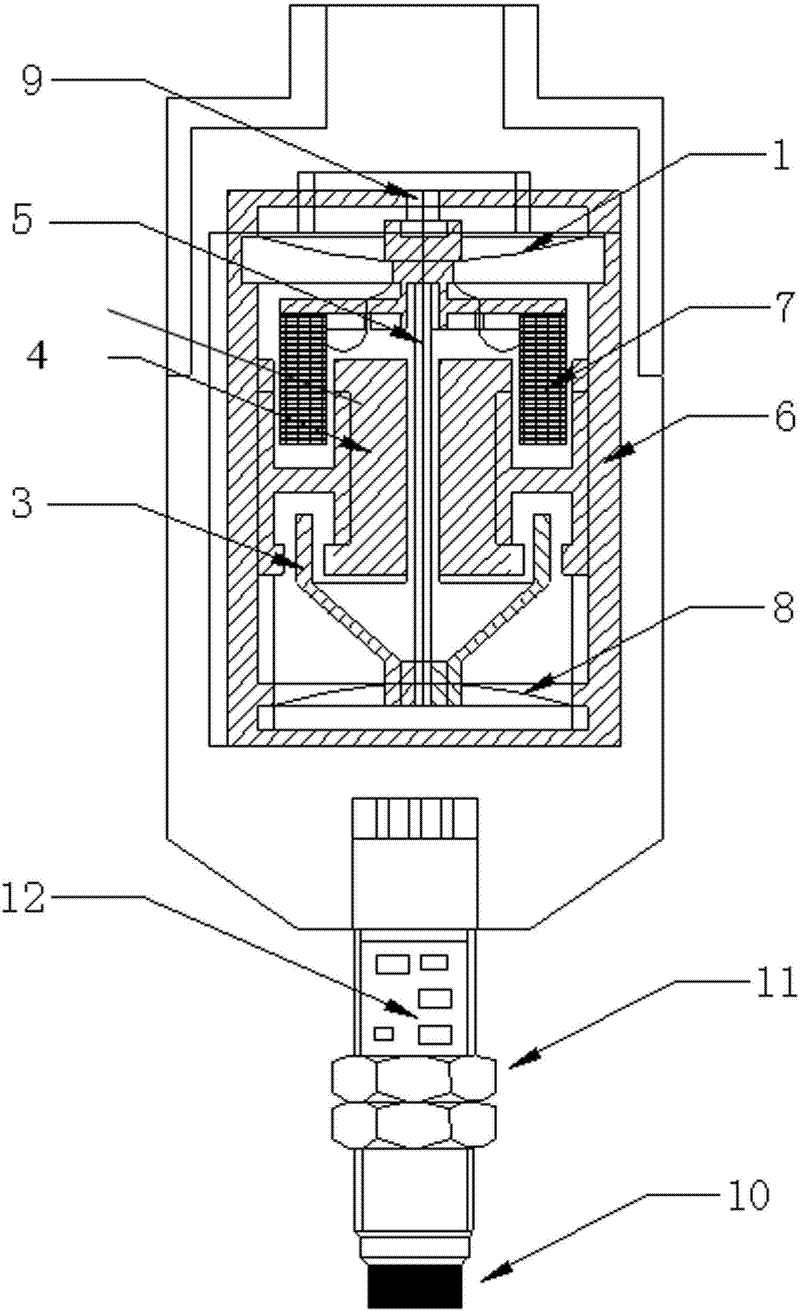

Multi-dimensional vibration sensor

A vibration sensor, speed sensor technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., to achieve the effect of convenient installation and use, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure of the present invention is shown in the figure. When the housing 6 of the sensor is fixed on the vibrating object, the entire sensor vibrates along with the vibrating object, and the vibrating coil 7 in the air gap is fixed with very soft reeds 1, 8 On the shell, its natural frequency ωn is relatively low. When the natural frequency ω≥1.5ωn, the moving coil is in a relatively static state (relative to the sensor housing), and relative movement occurs between the coil and the magnetic steel. The moving coil cuts the magnetic field lines and generates an induced electric potential E:

[0014] E=BLν

[0015] Where B-magnetic field strength

[0016] L-Induction coil magnetic field strength

[0017] ν-relative speed of motion

[0018] When B and L are constant, the output potential E is proportional to the vibration speed ν. Because the relative speed of its vibration is relative to a certain static point in space, it is also called an absolute speed sensor.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com