Hydraulic rotating device of gripping apparatus

A technology of hydraulic rotation and gripper, applied in the field of hydraulic rotation devices, can solve the problems of high maintenance rate, high cost, low reliability, etc., and achieve the effects of high reliability, low cost and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

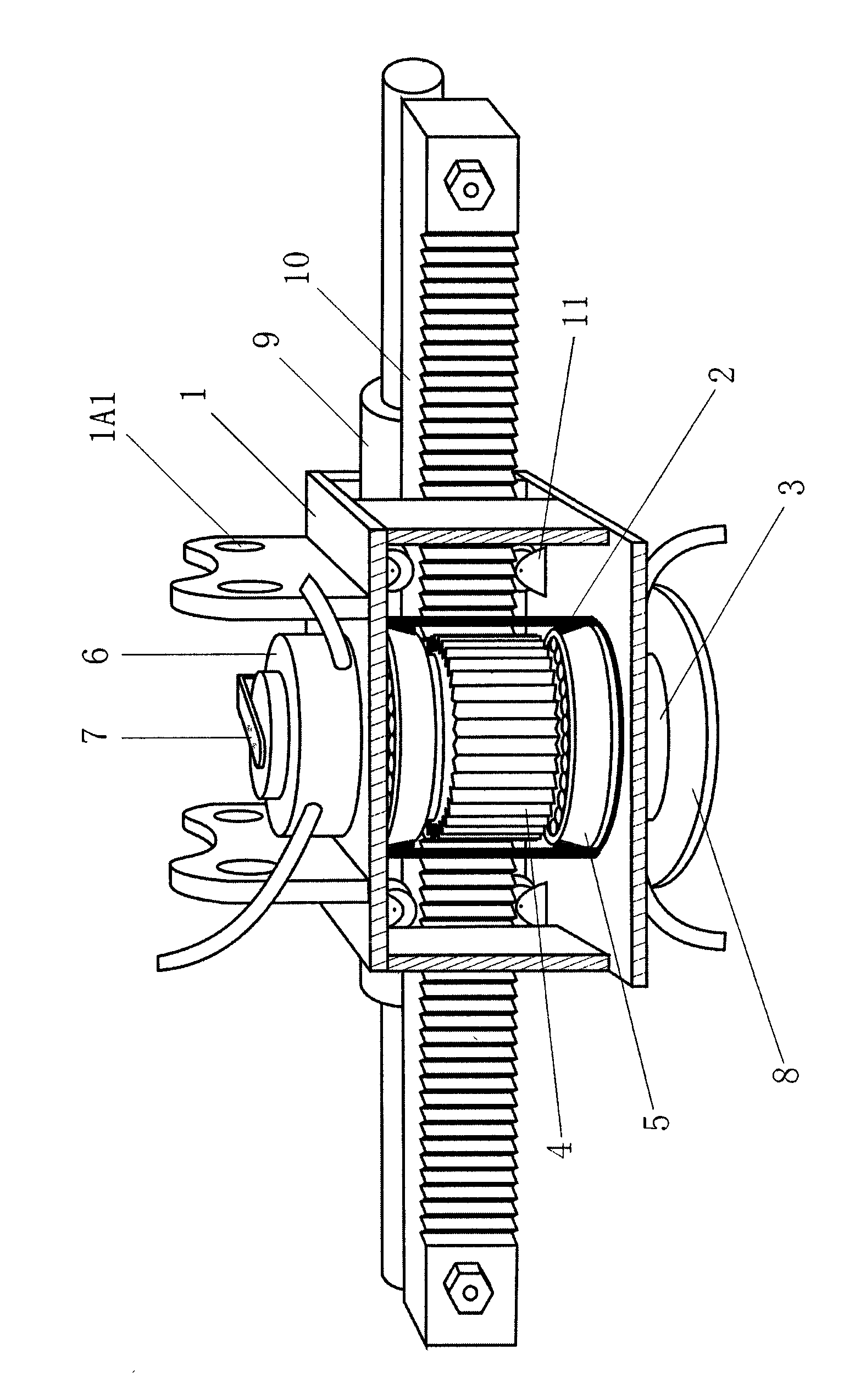

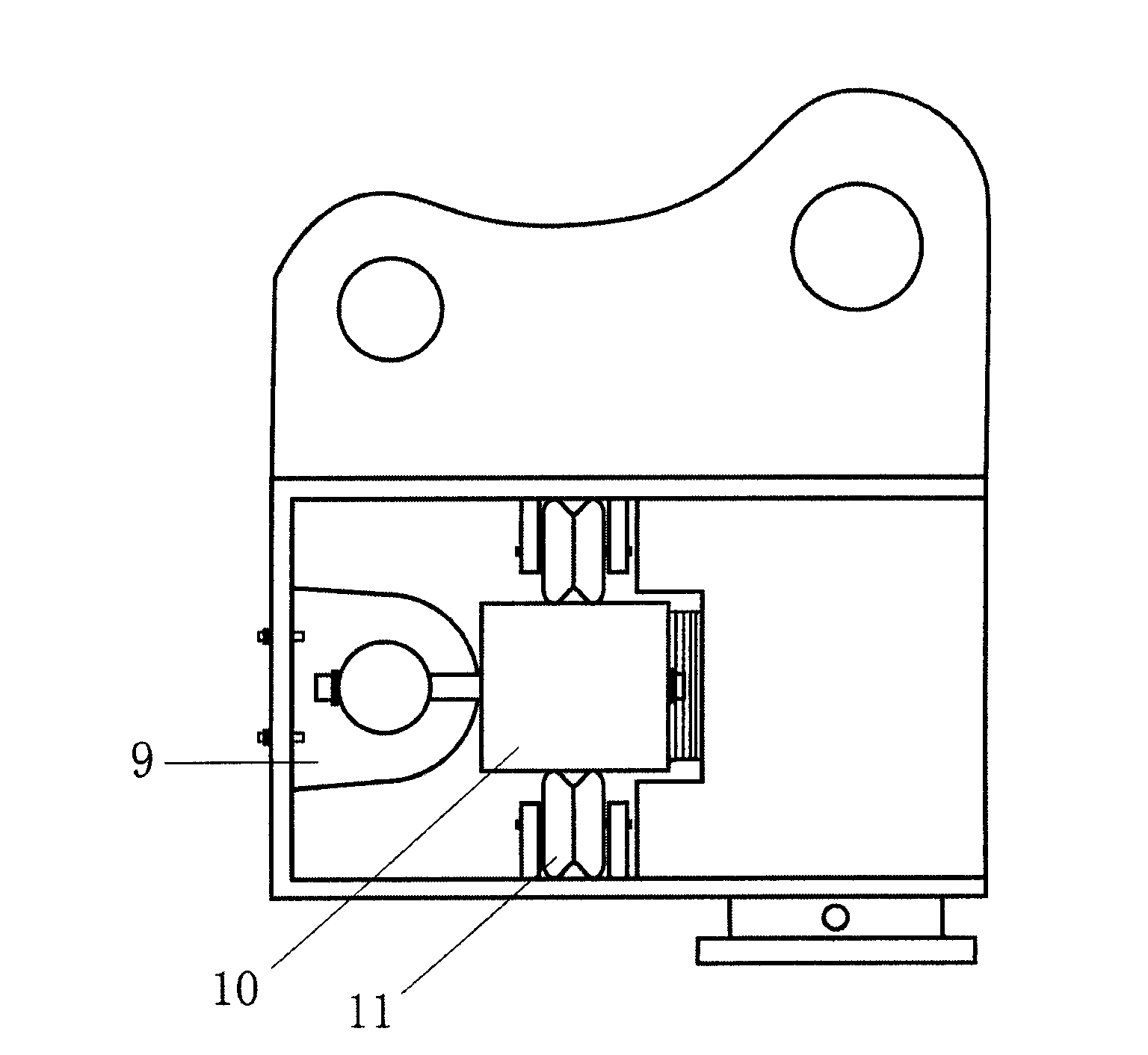

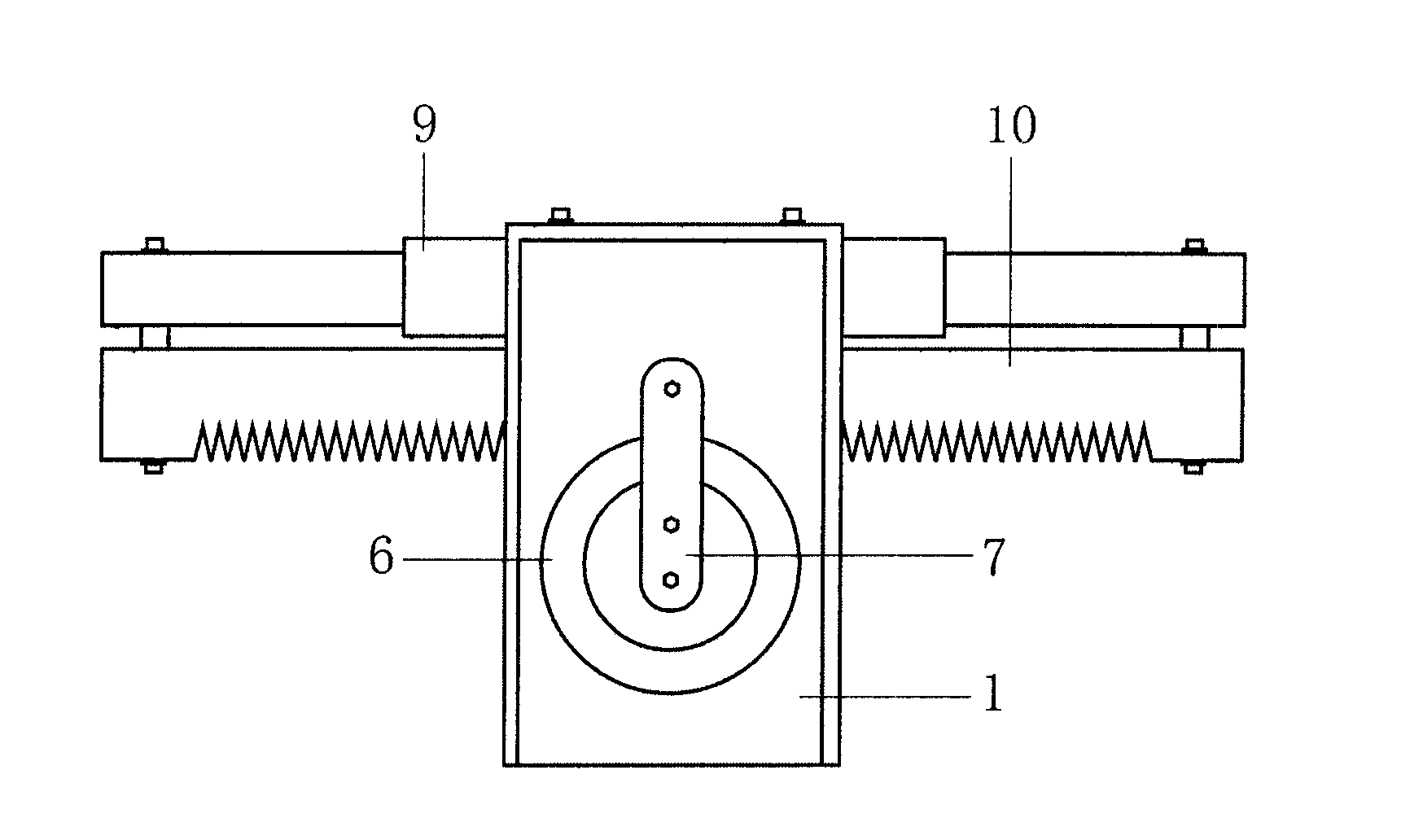

[0021] figure 1 Among them, the sleeve 2 is fixed inside the upper and lower sides of the box body 1; the gear plate 4 is fixed in the middle of the gripper shaft 3, the gear plate 4 is installed in the sleeve 2, and the upper and lower bearings 5 are respectively installed on the sleeve 2 from the upper and lower side holes of the box body 1. On the inner bearing position; the top of the gripper shaft 3 is installed with the oil distribution cup 6, the oil distribution cup 6 protrudes from the upper side of the box body 1, and the oil distribution cup 6, the fixed piece 7, and the upper side of the box body 1 are fixed together with screws The lower end of the gripper shaft 3 protrudes from the lower side of the box body 1, and the lower end of the gripper shaft 3 is welded and fixed with the center of gravity of the fixed plate 8 of the gripper device; a two-way oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com