Oil pump for chain saw

A chain saw and oil pump technology, applied in chainsaws, sawing equipment, sawing machine devices, etc., can solve the problems of easy blockage of oil outlets, waste of resources, easy oil leakage, etc., to improve service life, uniform oil output, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

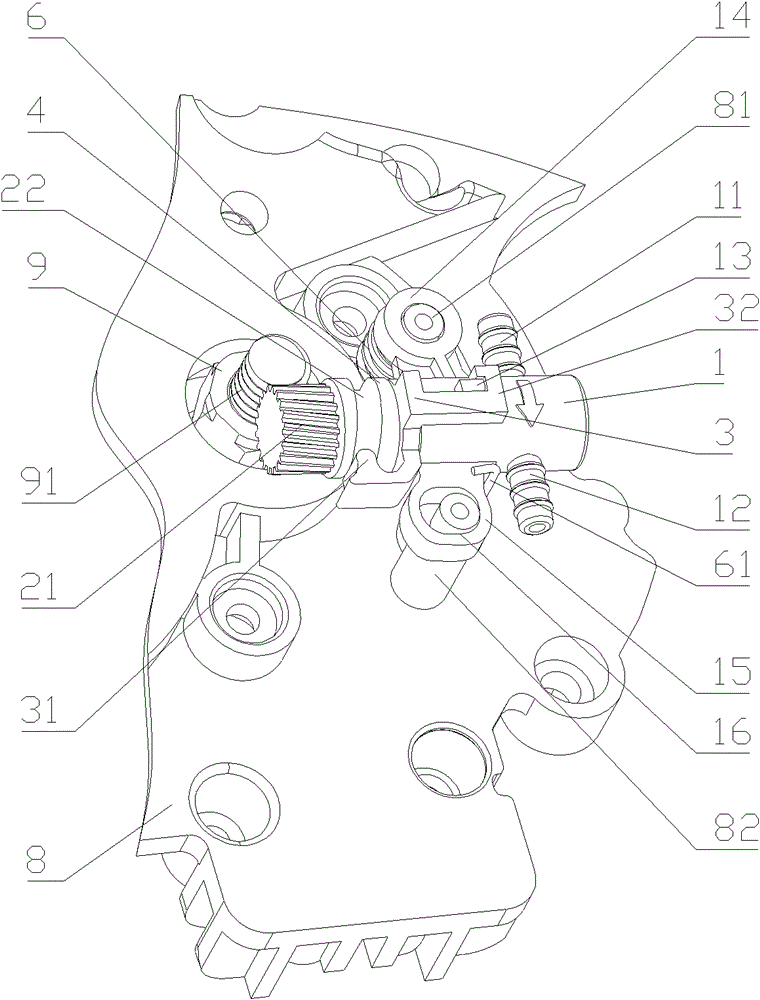

[0018] Such as Figures 1 to 3 Shown is a structural schematic diagram of an embodiment of the present invention, an oil pump for a chainsaw, including a pump body 1 arranged on a chainsaw support plate 8, the pump body is provided with an oil inlet 11 and an oil outlet 12, and the pump body There is a piston rod 2 that moves horizontally reciprocating relative to the pump body. A transmission mechanism is provided between the front end of the piston rod and the shaft head of the chainsaw output shaft 9 to make the piston rod rotate with the output shaft. There is a rotating guide structure between the pump bodies to make the piston rod reciprocate horizontally relative to the pump body when it rotates.

[0019] The transmission mechanism is an meshing transmission mechanism, which includes a worm wheel 21 arranged at the front end of the piston rod and a worm 91 arranged at the shaft head of the chainsaw output shaft to mesh with the worm wheel, and the said worm is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com