Automatic anchor chain transom welding device

An automatic welding and anchor chain technology, applied in the direction of metal chains, etc., can solve problems such as low welding speed, physical injury of welders, and impact on enterprise production efficiency, and achieve the effect of ensuring position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

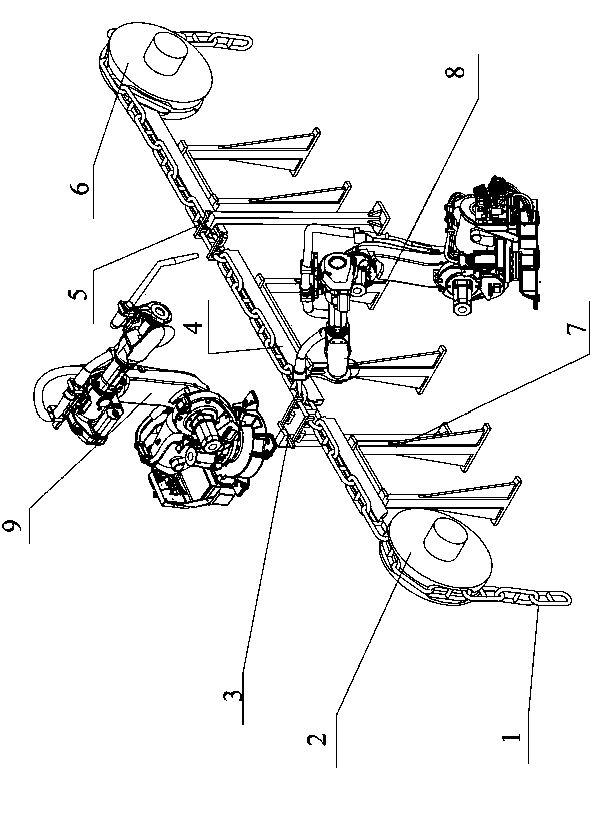

[0022] Embodiment one: see figure 1 , the automatic welding device for anchor chain crosspieces includes active guide wheels 2, passive guide wheels 6, transmission table 4, support 7, clamping mechanisms 3, 5 and welding robots 8, 9, and the transmission work is supported by the support 7 Platform 4, the active guide wheel 2 and the passive guide wheel 6 are respectively installed at both ends of the transmission workbench 4; , and drive the passive guide wheels (6) to rotate; each setting distance of the transfer table 4 has a welding station, and each welding station is provided with a clamping mechanism 3,5, which can Clamp the vertically placed welded anchor chain 1 chain link on the welding station; at each welding station, a welding robot 8, 9 is set to carry out the welding on the vertical chain link. welding.

Embodiment 2

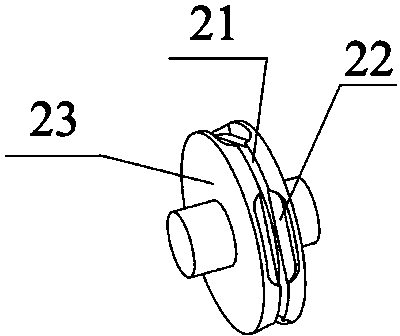

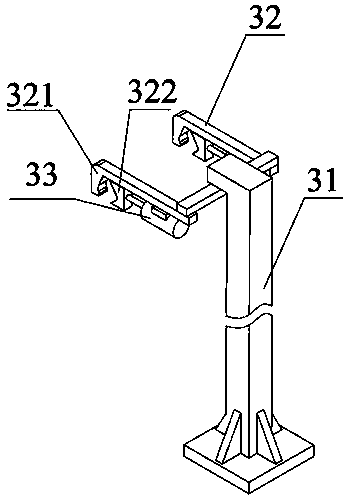

[0023] Embodiment two: see figure 1 , figure 2 and image 3 , the present embodiment is basically the same as Embodiment 1, and the special features are as follows: the rims of the wheel body 23 of the active guide wheel 2 and the passive guide wheel 6 are provided with grooves 21 and flat grooves 22 that are evenly distributed in the circumferential direction The anchor chain 1 to be welded is matched, that is, the number, structural size and spacing of the flat grooves 22 are determined according to the structural size of the anchor chain 1 to be welded, and the depth and width of the groove 21 are also determined according to the anchor chain 1 to be welded. The transfer table 4 and the bracket 7 are connected by bolts or welding. There is a groove member on the transmission table 4, the lower half of the vertically placed anchor chain link is in the groove, and the horizontally placed anchor chain link is on the table above the groove, so that the chain is guaranteed du...

Embodiment 3

[0024] Embodiment three: as figure 1 As shown, the anchor chain rung automatic welding device includes active guide wheels 2, passive guide wheels 6, transmission table 4, bracket 7, clamping mechanism 3 and clamping mechanism 5, welding robot 8 and welding robot 9.

[0025] The active guide wheel 2 and the passive guide wheel 6 are respectively located at the two ends of the transmission workbench 4. The active guide wheel 2 is driven to rotate by the power device, and the anchor chain of the anchor chain 1 is embedded in the groove of the two guide wheels. Driven by the anchor chain 1, it moves on the workbench 4 along the rotation direction of the active guide wheel 2, and the passive guide wheel 6 rotates with the movement of the anchor chain under the action of the anchor chain 1.

[0026] Such as figure 2 As shown, there are grooves 21 and flat grooves 22 on the wheel body 23 of the active guide wheel 2 and the passive guide wheel 6. The number, structural size and spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com