Data processing method, device and manufacturing method for applying phosphor to LED

A technology of data processing and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., to achieve the effect of saving resources and costs, improving utilization efficiency, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

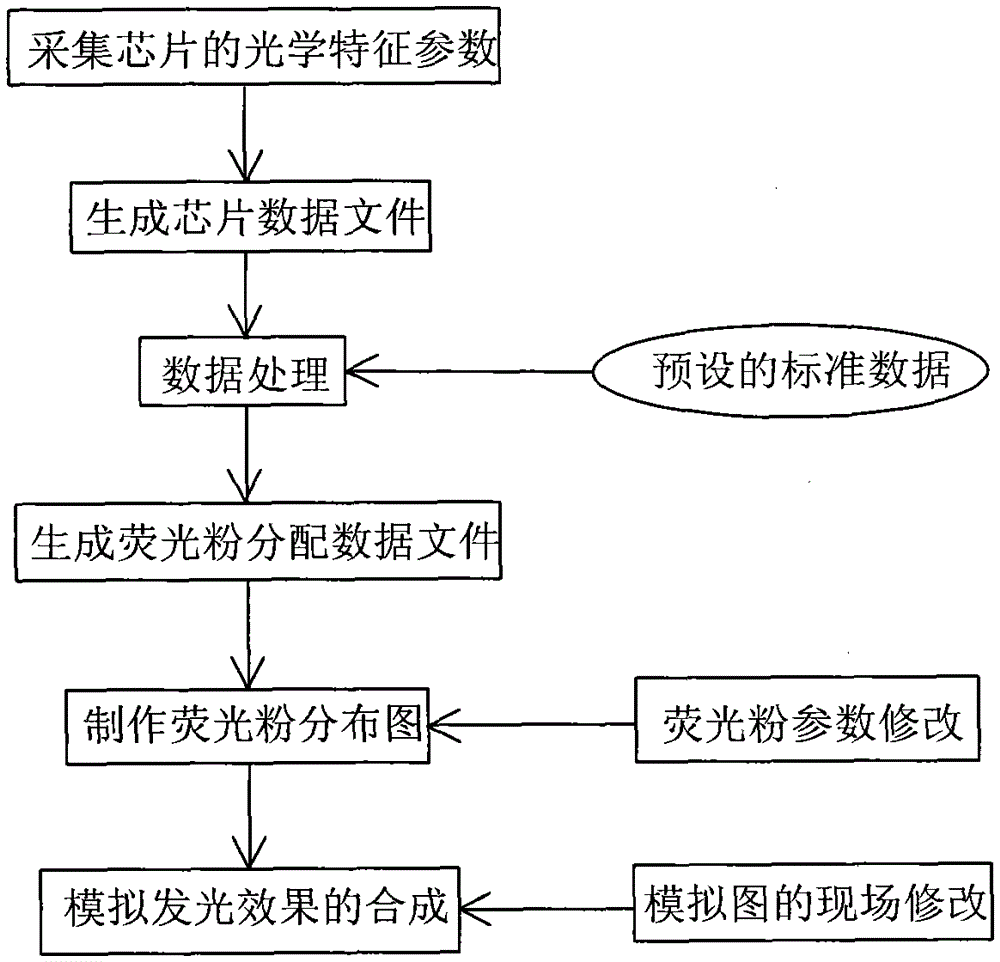

[0040] The present invention proposes a data processing method for applying fluorescent powder to LED, see figure 2 As shown, the optical characteristic parameters of the chip need to be collected before data processing. The optical characteristic parameters are mainly the main wavelength and optical power of the spot measurement output, and can also include other optical characteristic parameters, such as forward voltage, reverse breakdown voltage and lifetime. parameters etc. Then process the collected optical characteristic parameters of the chip to generate a chip data file. The chip data file can be converted into a data file directly executed by the phosphor powder application device, or a data file for further processing.

[0041]The generated chip data file is combined with the preset standard data for data processing to generate a phosphor distribution data file. The preset standard data is mainly that the chipset as a whole should have effect characteristics such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com