Vertical float switch

A float switch, vertical technology, applied in the field of vertical float switches, can solve the problems affecting the accuracy of the switch action, not easy to separate, increase the float switch, etc., to achieve a wide range of applicable space, long mechanical and electrical life , The effect of stable transmission signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be further described in detail below.

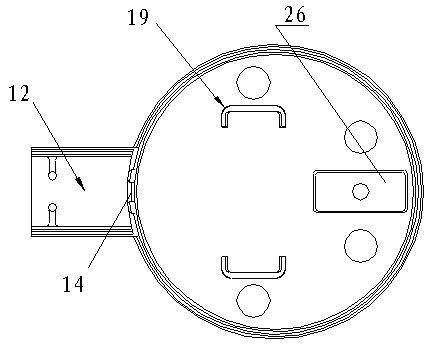

[0028] Such as Figures 1 to 10 As shown, a vertical float switch according to the first embodiment of the present invention includes a hollow housing 10 . The lower left part of the housing 10 is provided with an outwardly protruding sealing liquid cylinder 12 with an opening, and a core wire support 14 is provided on the housing 10 where the sealing liquid cylinder 12 is connected. Along the central axis of the sealing liquid cylinder 12 , the casing 10 is divided into a lower casing 16 and an upper cover 18 . After all the equipment inside the casing 10 is installed, the lower casing 16 and the upper cover 18 are welded together, and then the sealing liquid is poured into the sealing liquid cylinder 12, so that the entire casing 10 forms a sealed whole. The bottom of the lower housing 16 is provided with two symmetrical slots 19, and the switch bracket 20 is fixed by means of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com