Oil reservoir for heating diesel oil

A diesel heating and storage technology, which is applied in the direction of machines/engines, engine starting, fuel heat treatment devices, etc., can solve the problems of increasing transportation costs, increasing fuel consumption, and damaging batteries, so as to ensure normal operation and reduce oil consumption cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

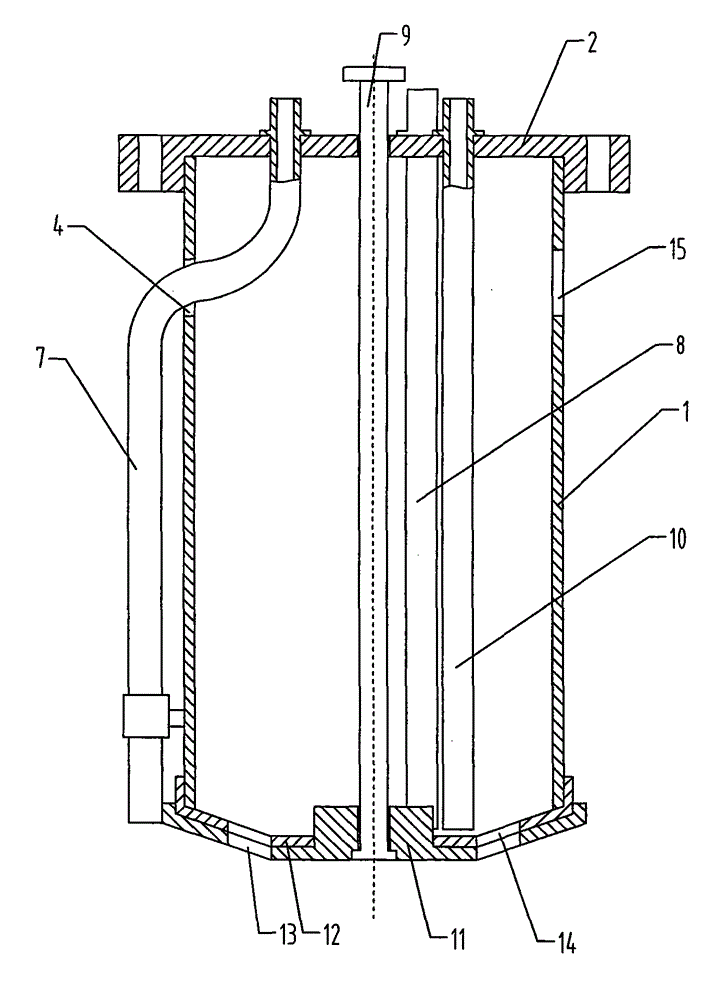

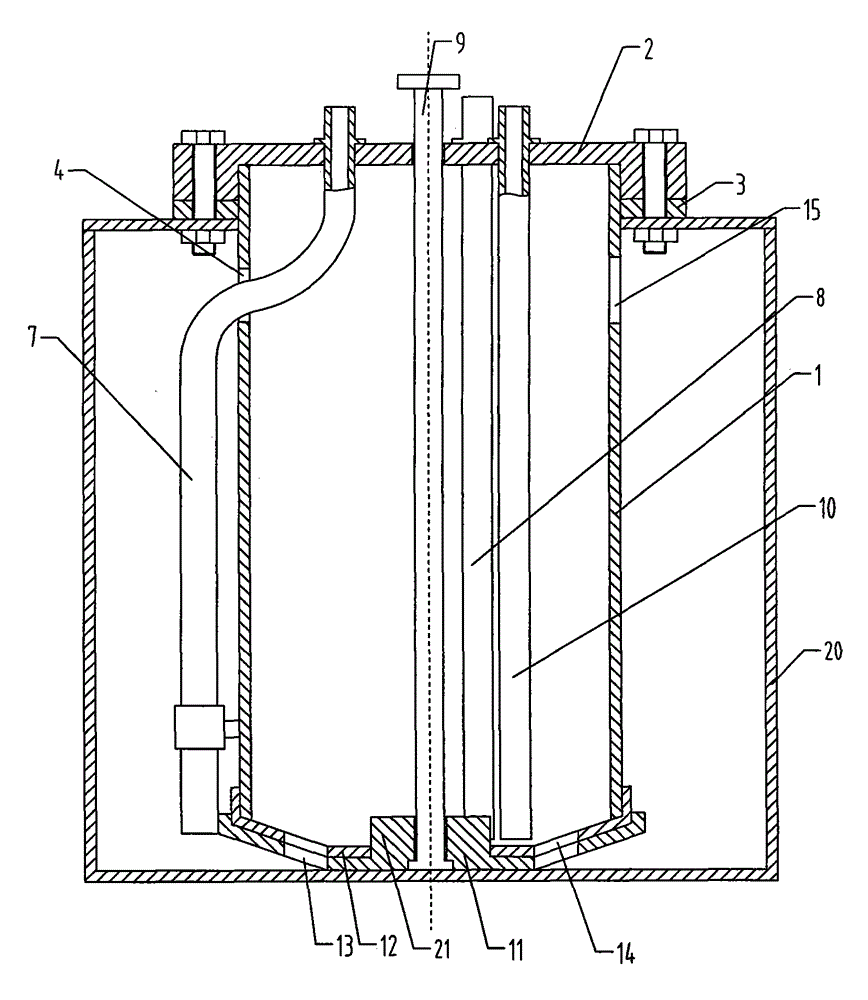

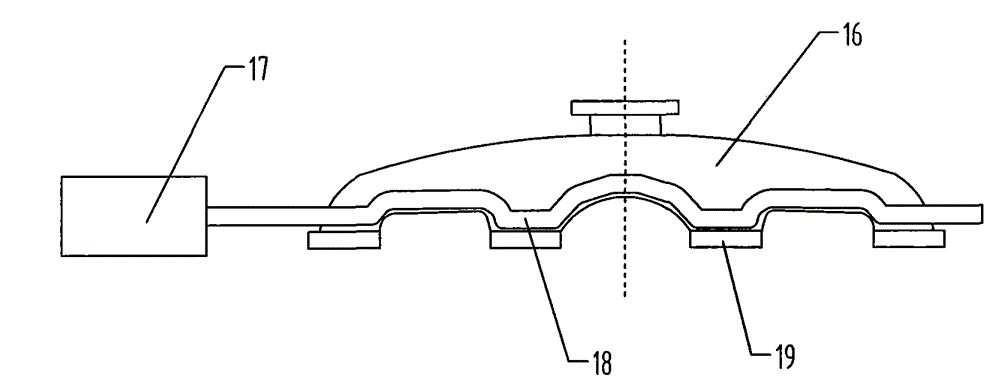

[0033] Examples such as figure 1 As shown, an oil storage device for diesel heating includes a cylinder body 1, an upper cover 2 is provided on the upper part of the cylinder body 1, and it is characterized in that: an oil outlet pipe 8 and an oil suction pipe are arranged inside the cylinder body 1 7 and the oil return pipe 10, the upper ends of the oil outlet pipe 8, the oil suction pipe 7 and the oil return pipe 10 respectively pass through the upper cover 2 and protrude to the outside of the cylinder 1, the upper end of the oil suction pipe 7 and the upper end of the oil return pipe 10 A heating oil pipe 18 is connected between them, and a heating device is arranged on the heating oil pipe 18 .

[0034] The lower ends of the oil outlet pipe 8 and the oil return pipe 10 are arranged near the bottom of the cylinder 1 , and the oil suction pipe 7 passes through the shell wall of the cylinder 1 and its lower end is arranged near the bottom of the cylinder 1 .

[0035] A long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com