Device and method for separating and recovering silicon and silicon carbide in cutting waste mortar of silicon wafers

A silicon wafer cutting and silicon carbide technology, which is applied in the direction of separation methods, chemical instruments and methods, silicon compounds, etc., can solve the problems of difficult sample classification and collection, environmental pollution, and low product purity, so as to maximize social and economic benefits and reduce Environmental pollution, the effect of improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

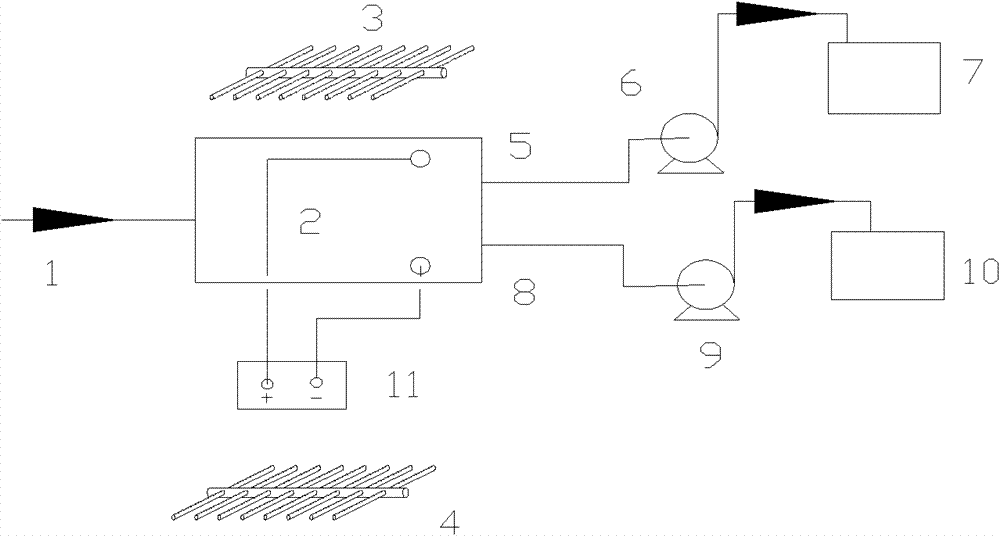

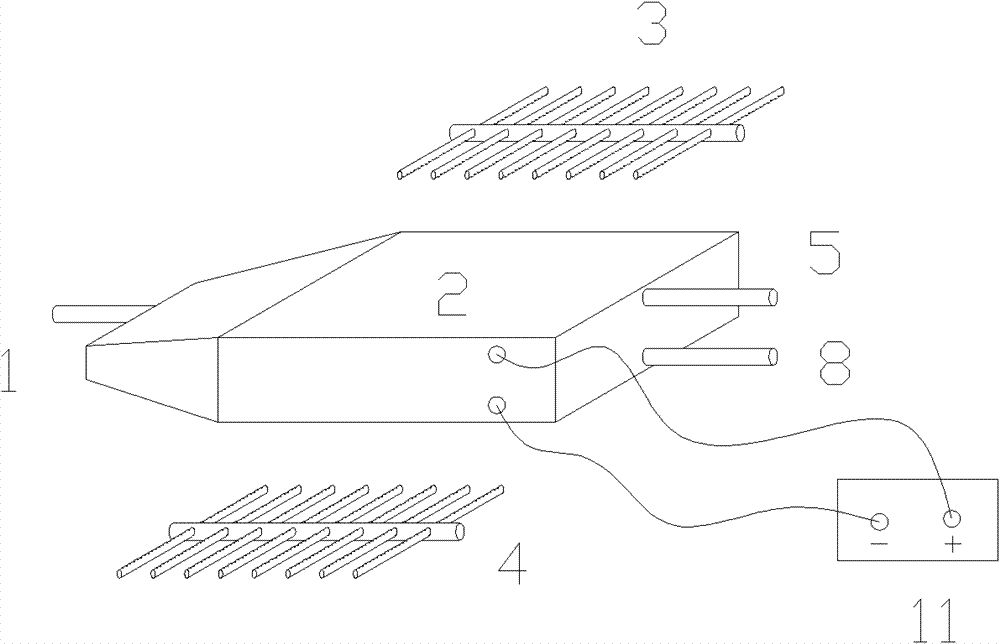

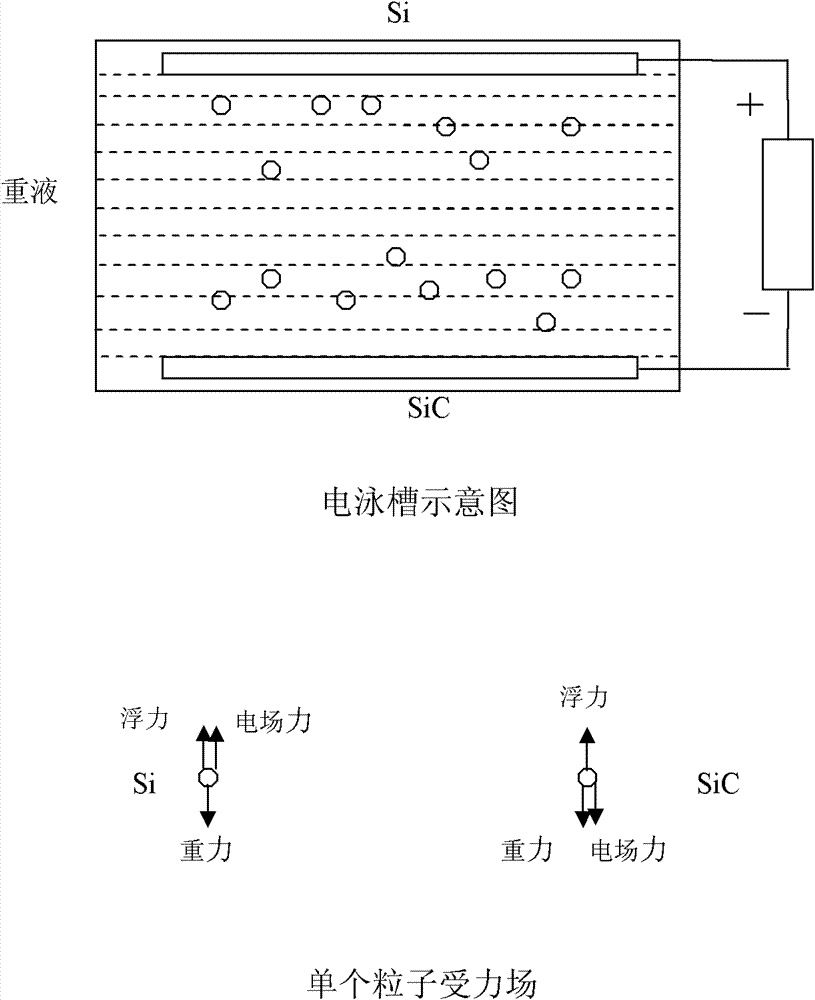

Method used

Image

Examples

Embodiment 1

[0026] Using the device and method for separating silicon and silicon carbide in silicon wafer cutting waste mortar according to the present invention, wherein the polyethylene glycol content of the waste mortar component is 41%, the SiC content is 46%, the Si content is 10%, and other impurities are 3%. Specifically include the following steps:

[0027] 1. Separating the waste mortar from silicon wafer cutting into solid and liquid. The obtained solid is decontaminated by hydrochloric acid solution. After deacidification by centrifugation, it enters the water washing tower for water washing. Excess water is removed by centrifugation, and the acid is recycled through membrane filtration.

[0028] 2. The solid phase after impurity removal is added to the sodium polytungstate aqueous solution with a density of 2.35 for ultrasonic vibration dispersion, and the ratio is 1:10g / mL; at the same time, a gum arabic dispersant with a solid phase amount of 0.1% w / v is added to obtain Was...

Embodiment 2

[0031] Utilize the device and process for separating and recovering silicon and silicon carbide in waste mortar for cutting silicon wafers according to the present invention, wherein the content of polyethylene glycol in the waste mortar component is 41%, the content of SiC is 46%, the content of Si is 10%, and the content of other impurities is 3%. . Specifically include the following steps:

[0032] 1. Separating the waste mortar from silicon wafer cutting into solid and liquid, adding sulfuric acid solution to the obtained solid to remove metal impurities, after centrifuging to remove acid, enter the water washing tower for water washing, centrifuging to remove excess water, and acid to be recycled through membrane filtration.

[0033] 2. The solid phase after impurity removal is added to the aqueous solution of sodium polytungstate with a density of 2.6 for ultrasonic vibration dispersion, and the ratio is 1:5g / mL; at the same time, add gum arabic-ammonium polyacrylate wit...

Embodiment 3

[0036] Utilize the device and process for separating and recovering silicon and silicon carbide in waste mortar for cutting silicon wafers according to the present invention, wherein the polyethylene glycol content of the waste mortar component is 35%, the SiC content is 33%, the Si content is 9%, and other impurities are 15%. , including the following steps:

[0037] 1. Separating the waste mortar from silicon wafer cutting into solid and liquid, adding nitric acid solution to the obtained solid to remove metal impurities, after centrifuging to remove acid, enter the water washing tower for water washing, centrifuging to remove excess water, and acid to be recycled through membrane filtration.

[0038] 2. After removing impurities, add sodium polytungstate aqueous solution with a density of 3 for ultrasonic vibration dispersion, and the ratio is 1:2g / mL; at the same time, add sodium hexametaphosphate dispersant with a solid phase amount of 1% w / v , to obtain a heavy liquid su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com