Calibration method of near-infrared camera

A calibration method, near-infrared technology, is applied in the field of calibration for near-infrared cameras, and can solve problems such as non-coplanar marking points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

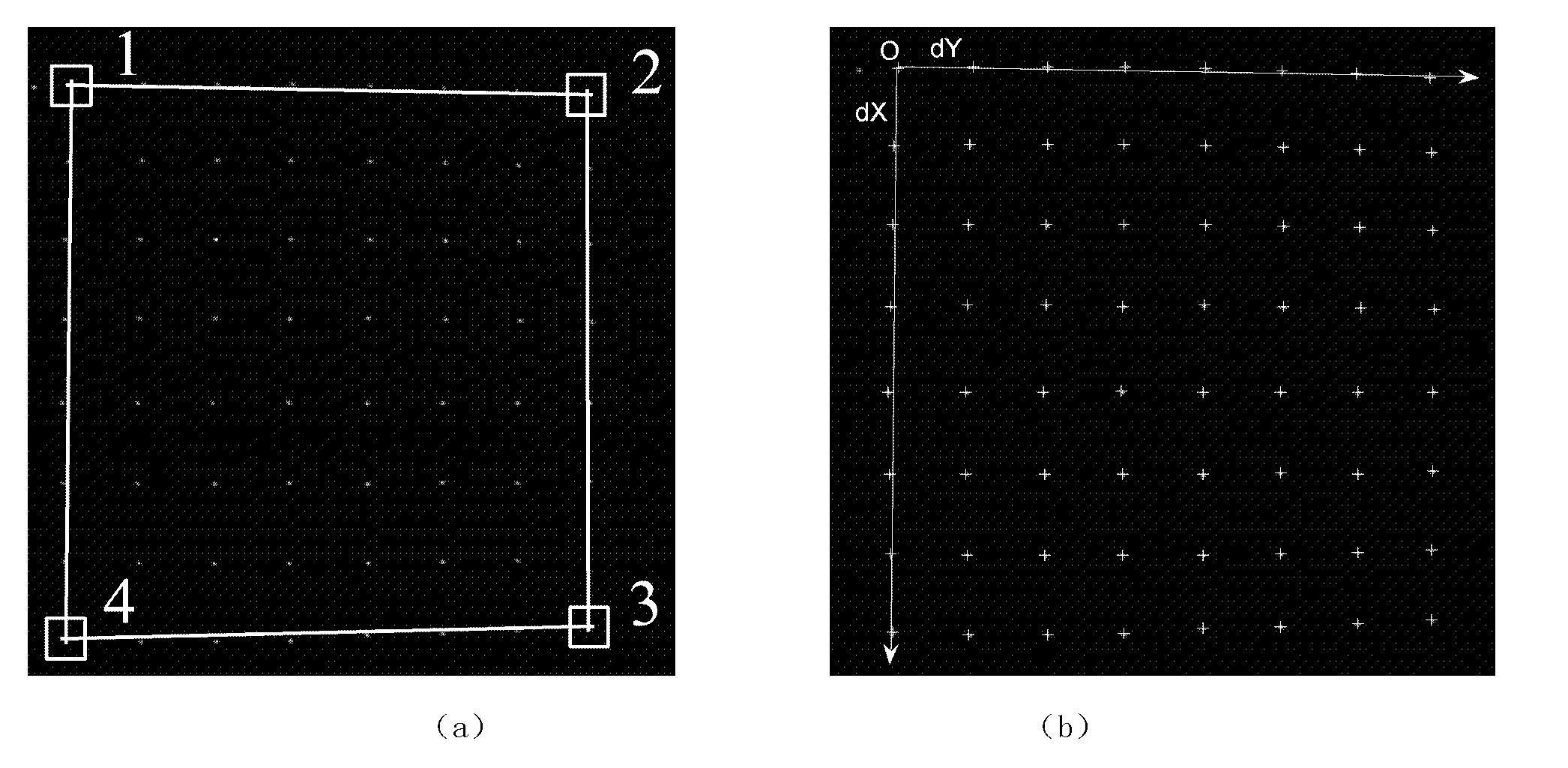

[0022] In order to better understand the technical solution of the present invention, a detailed description is given below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the present invention provides a method for calibrating a near-infrared camera. The calibration steps are as follows:

[0024] Step 1: Make a calibration board, use an 8×8 array of near-infrared light-emitting points as 64 calibration points, and add a near-infrared light-emitting point next to the calibration point in the corner of the array light-emitting area as the initial calibration point.

[0025] Step 2: Place the near-infrared calibration board within the effective field of view in front of the near-infrared camera, and adjust the camera's focal length, aperture, etc., so that the camera can clearly capture the texture of the calibration board. Then change the placement position of the calibration plate, and take a series of images at different positions. exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com