Belt full width tensile fixture and horizontal belt tensile testing machine

A technology of tensile testing machine and fixture, which is applied in the direction of strength characteristics, using stable tension/compression to test material strength, measuring devices, etc., can solve the problems of inability to do breaking test and difficult to deal with, and achieve production cost and test cost Low cost, simple structure, and the effect of reducing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

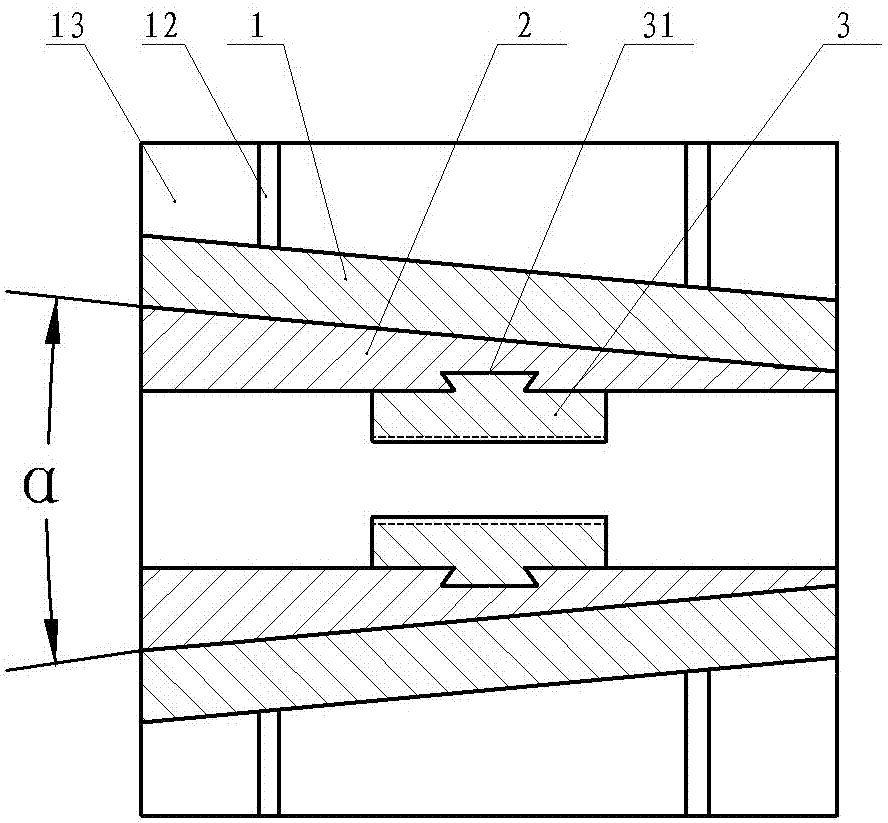

[0031] Embodiment one: see figure 1 , figure 2 , image 3 . A full-width belt stretching fixture, vertically fixing two vertical plates 1 on the bottom plate, the outer surfaces of the two vertical plates 1 are not limited but the inner surfaces are inclined and symmetrical, and the angle between the inner surfaces of the two vertical plates 1 is α, And 13°≤α≤23°.

[0032] Two symmetrical wedge-shaped slide plates 2 are respectively matched and attached to the inner surfaces of the two vertical plates 1, so that the angle between the outer surfaces of the two wedge-shaped slide plates 2 is also α, and 13°≤α≤23°. The inner surfaces of the two wedge-shaped slide plates 2 are parallel to each other.

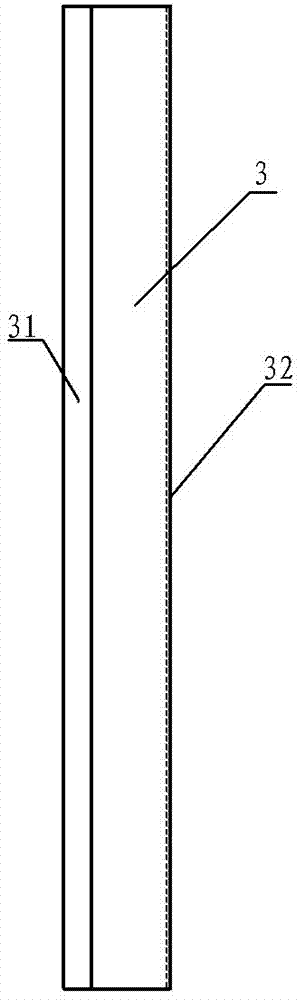

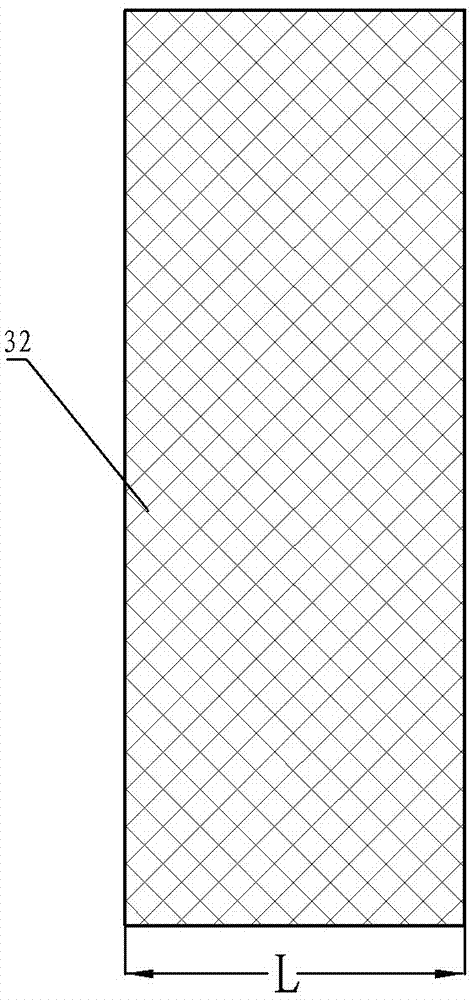

[0033] The inner surface of each wedge-shaped sliding plate 2 and the clamping block 3 are connected together through a vertically arranged dovetail groove and a dovetail strip 31 matching structure. The inner surface of the clamping block 3 is a friction surface 32 with reti...

Embodiment 2

[0035] Embodiment two: see figure 1 , figure 2 , image 3 . A full-width belt stretching jig, the jig is the same as the first embodiment, and will not be repeated, the difference is that the angle between the inner surfaces of the two vertical plates 1 is α, and 15°≤α≤20°. Therefore, the angle between the outer surfaces of the two wedge-shaped slide plates 2 is also α, and 15°≤α≤20°. The range of the width L of the rubbing surface 31 is 300mm, or 340mm, or 350mm, etc.

Embodiment 3

[0036] Embodiment three: accompanying drawing is not drawn. A fixed-installed full-width belt tensile jig, the jig is the same as in Embodiment 1, and will not be repeated, the difference is that the two vertical plates 1 are directly fixed on the base plate 4 of the tensile testing machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com