Ventilation control system and method applicable to dry type slag extractor

A technology of ventilation control system and dry slag discharger, which is applied in the combustion method, combustion control, air supply adjustment and other directions, can solve the problems of rising exhaust gas temperature, blockage of pressure transmission pipes, damage to meters, etc., to reduce exhaust emissions. Effects of slag heat loss, reduction of exhaust gas temperature, and reduction of exhaust heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further elaborated below in combination with the accompanying drawings and the embodiments.

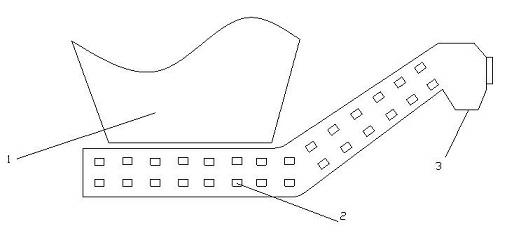

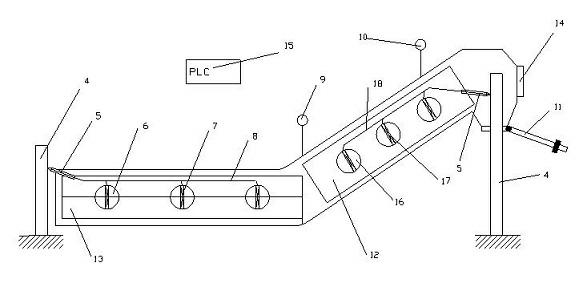

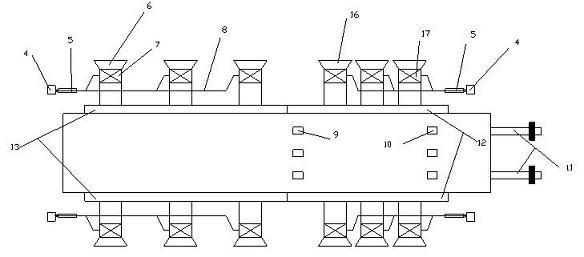

[0028] figure 1 , figure 2 , image 3 Among them, it includes a slag discharger, and the cold ash hopper 1 is installed on the slag discharger. In order to facilitate the control of the amount of cold air and reduce the complexity of the equipment, the slag discharger is divided into a horizontal section and an inclined section, and a ventilation device 2 is provided in the horizontal section and the inclined section, and the end of the inclined section is a slag outlet 3; The ventilation control unit 15 (it can be a PLC control unit) is connected, and at the same time, a first-level temperature measuring device and a second-level temperature measuring device are respectively arranged at the intersection of the horizontal section and the inclined section and the upper part of the inclined section. Connected to ventilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com