Guide shield for pushing rectangular concrete frame bridge

A frame bridge and concrete technology, which is applied in erecting/assembling bridges, bridges, earthwork drilling and mining, etc., can solve problems such as landslides, safety accidents, and large exposed area of subgrade soil layer, so as to avoid offset and reduce exposed area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

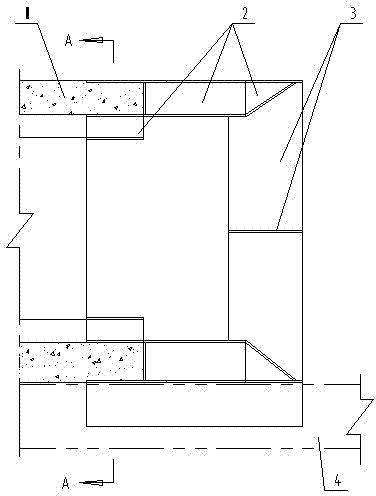

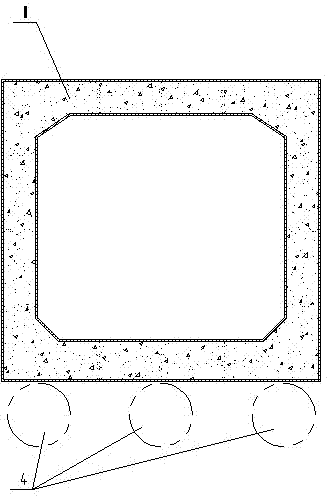

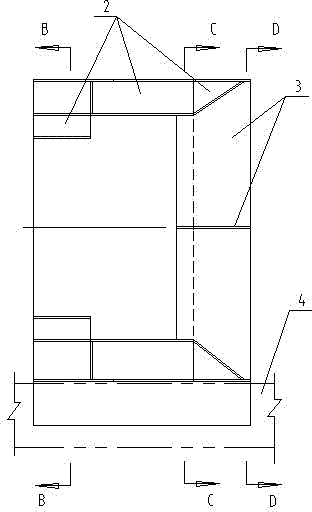

[0017] Example 1 as attached Figure 1-6 As shown: a guide shield for pushing a rectangular concrete frame bridge includes a prefabricated rectangular concrete frame bridge for roads or railways according to engineering design, and a rectangular metal frame structure 2 is prepared at the front end of the prefabricated rectangular concrete frame bridge 1, and the rectangular metal frame The rear end of the structure 2 has the same section size as the front end of the rectangular concrete frame bridge 1, and the steel bars at the front end of the rectangular concrete frame bridge 1 are welded into one body with the rear end of the rectangular metal frame structure 2. The four sides of the rectangular metal frame structure 2 are box-shaped structures, which are strong and compressive, and can bear the huge load on the upper part of the frame bridge or frame culvert, and can meet the requirements of normal operation of high-speed railways and expressways during roadbed constructi...

Embodiment 2

[0018] Example 2 as attached Figure 1-6 As shown: the front hollow cavity of the rectangular metal frame structure 2 described in Example 1 can also be welded with grid steel plates 3 that are evenly distributed vertically and horizontally, in which there is one longitudinal steel plate or one transverse steel plate, and the thickness of the steel plates is 12 --22mm, divide the front inner cavity of the rectangular metal frame 2 into four-hole grid units; the exposed area of each grid unit is only 1 / 4 of the inner cavity of the rectangular metal frame 2, and the soil is The grid unit is in a stable state, which can avoid safety accidents caused by landslides.

Embodiment 3

[0019] Example 3: The front hollow cavity of the rectangular metal frame structure 2 described in Embodiment 1 can also be welded with grid steel plates 3 that are evenly distributed vertically and horizontally and crosswise, wherein the uniformly distributed longitudinal steel plates and transverse steel plates are each two pieces, and the rectangular metal frame The front cavity of structure 2 is divided into nine-hole grid units; the exposed area of each grid unit is only 1 / 9 of the cavity of the rectangular metal frame structure 2, which greatly reduces the exposed area of the unit, and is suitable for jacking large sections Rectangular concrete frame bridge or frame culvert.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com