Natural-color cigarette cardboard and production method thereof

A production method and an original technology, applied in the field of papermaking, can solve the problems of intractable waste water, excessive heavy metals in volatiles, unfavorable environmental protection requirements, etc., and achieve the effects of good surface flatness, consumption saving, and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

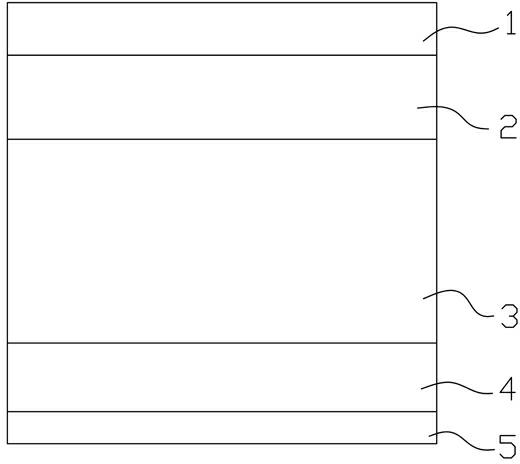

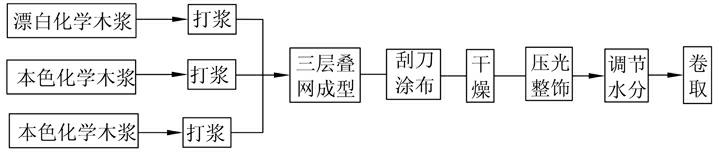

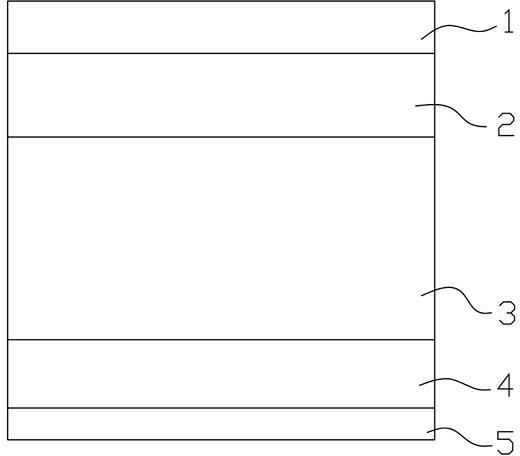

[0034] Embodiment 1 (220g / m 2 natural color cigarette cardboard)

[0035] Surface layer pulping: pulp board (chemical pulp long fiber: chemical pulp short fiber = 20:80) is crushed by a hydraulic pulper and then beaten (if it is self-made pulp, it is directly beaten), and then batched to obtain bleached chemical wood pulp.

[0036] Core layer pulping: natural color pulp board (natural color chemical pulp: natural color mechanical pulp = 60:40) is crushed by a hydraulic pulper and then beaten (if it is self-made pulp, it is directly beaten), and then batched to obtain natural color chemical pulp wood pulp.

[0037] Bottom layer pulping: unbleached pulp boards (all unbleached chemical pulp) are crushed by a hydraulic pulper and then beaten (if it is self-made pulp, it is directly beaten), and then batched to obtain unbleached chemical wood pulp.

[0038] The chemicals and their amounts added in the pulping process are: rosin 1.7KG / ton of paper; aluminum sulfate 7.8KG / ton of p...

Embodiment 2

[0044] Embodiment 2 (230g / m 2 natural color cigarette cardboard)

[0045] The production process of this embodiment is basically the same as that of Example 1, wherein the ratio of the long fibers of the pulp and the short fibers of the pulp used in the pulping process of the surface layer is 15:85, and the pulping process of the core layer uses The ratio of natural chemical pulp and natural mechanical pulp is 55:45. All the raw chemical pulp used in the pulping process of the bottom layer is natural chemical pulp. The chemicals and their amount added in the pulping process are: rosin 1.9KG / ton of paper; Aluminum sulfate 8.0 KG / ton of paper; cationic starch 4.9KG / ton of paper; fungicide 1.0KG / ton of paper; defoamer 0.25KG / ton of paper, three-layer quantitative: surface layer: 65 g / m 2 Core layer: 120g / m 2 Bottom layer: 45g / m 2 , the paint used for the coating layer on the surface layer is prepared from 25% china clay, 60% calcium carbonate, 15% latex, 0.15% dispersant, 0.3...

Embodiment 3

[0049] Embodiment 3 (210g / m 2 natural color cigarette cardboard)

[0050] The ratio of chemical pulp long fiber and chemical pulp short fiber used in the surface layer pulping process is 15:85, and the ratio of natural color chemical pulp and natural color mechanical pulp used in the core layer pulping process is 70:30 , all used in the pulping process of the bottom layer is natural chemical pulp. The chemicals and their amounts added in the pulping process are: rosin: 1.5 KG / ton of paper; aluminum sulfate: 7.0KG / ton of paper; cationic starch: 5.0 KG / ton of paper; fungicide: 1.0KG / ton of paper; defoamer 0.2 KG / ton of paper, three-layer quantitative: surface layer: 60g / m 2 Core layer 110g / m 2 Bottom layer: 40g / m 2 , the paint used for the coating layer on the surface layer is prepared from 25% china clay, 60% calcium carbonate, 15% latex, 0.15% dispersant, 0.3% water repellant, and 0.6% lubricant. The cloth weight is 2g / m 2 .

[0051] After a comparison test with the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com