Clucking power feedback system in touching device

A feedback system and clamping force technology, applied in the field of clamping joints and the realization of force feedback, can solve problems such as poor versatility, and achieve the effects of easy implementation, compact structure, improved presence and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

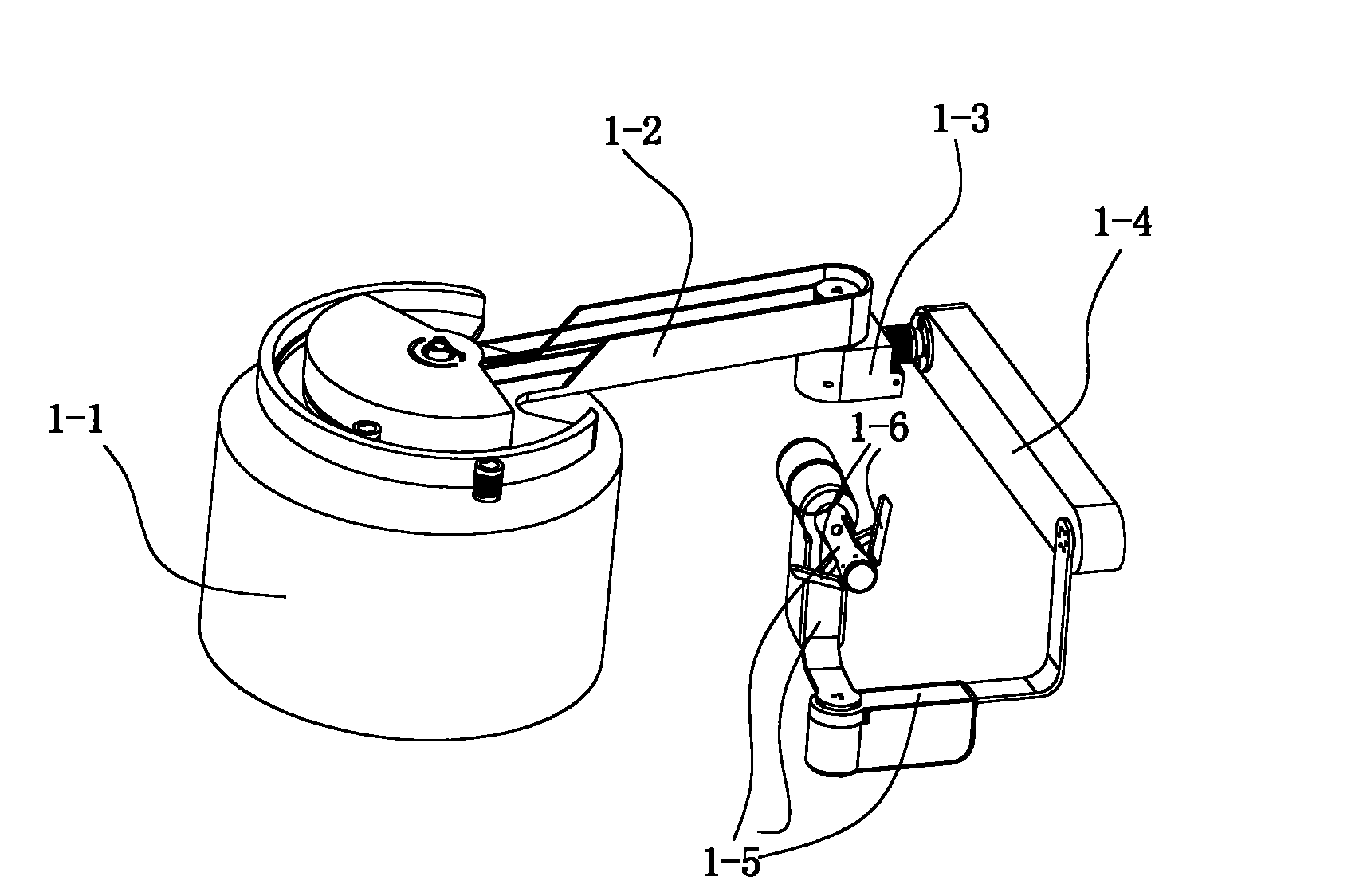

[0015] figure 1 It is an application example of the present invention in the master operator system of the master-slave teleoperation robot. figure 1 The main manipulator system includes: base 1-1, arm mechanism 1-2, elbow joint mechanism 1-3, forearm mechanism 1-4, wrist joint structure 1-5 and clamping force feedback system 1-6 of the present invention . In this example, the present invention is directly connected with the attitude frame of the wrist joint structure 1-5 of the main manipulator system, that is, the attitude frame replaces the shell and exists as a support. This wrist joint is a structure where three axes meet at one point, and the clamping force of the present invention The feedback system can also be applied to other wrist structures or exist independently in other system structures.

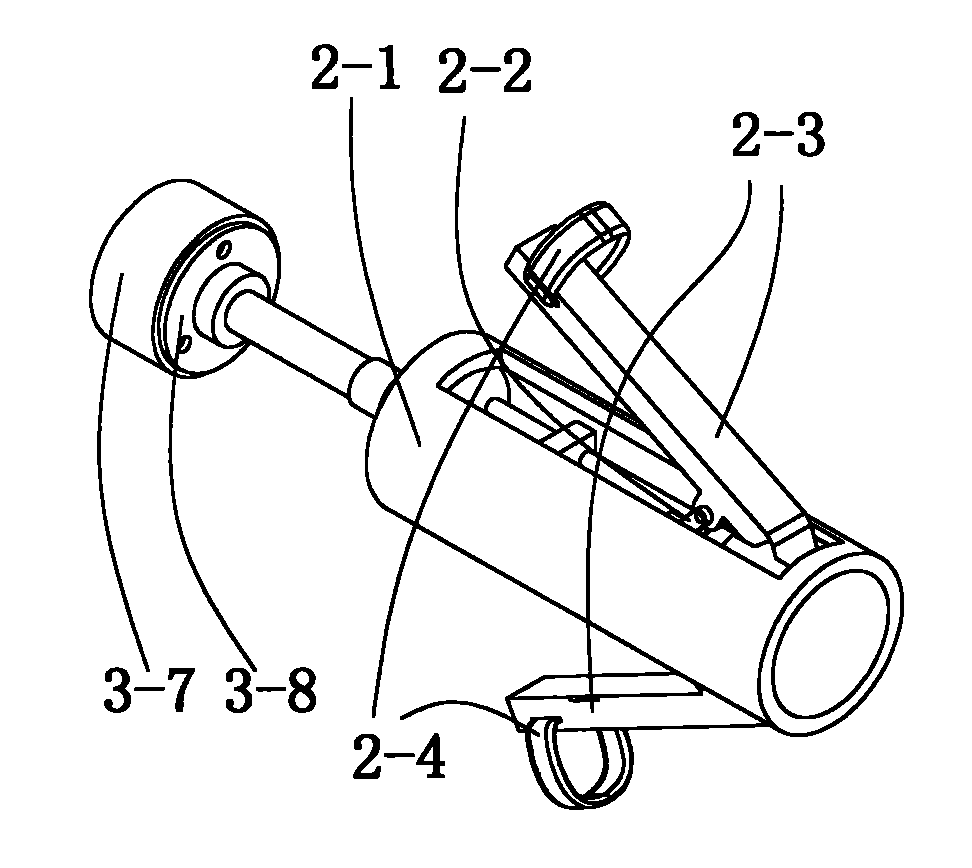

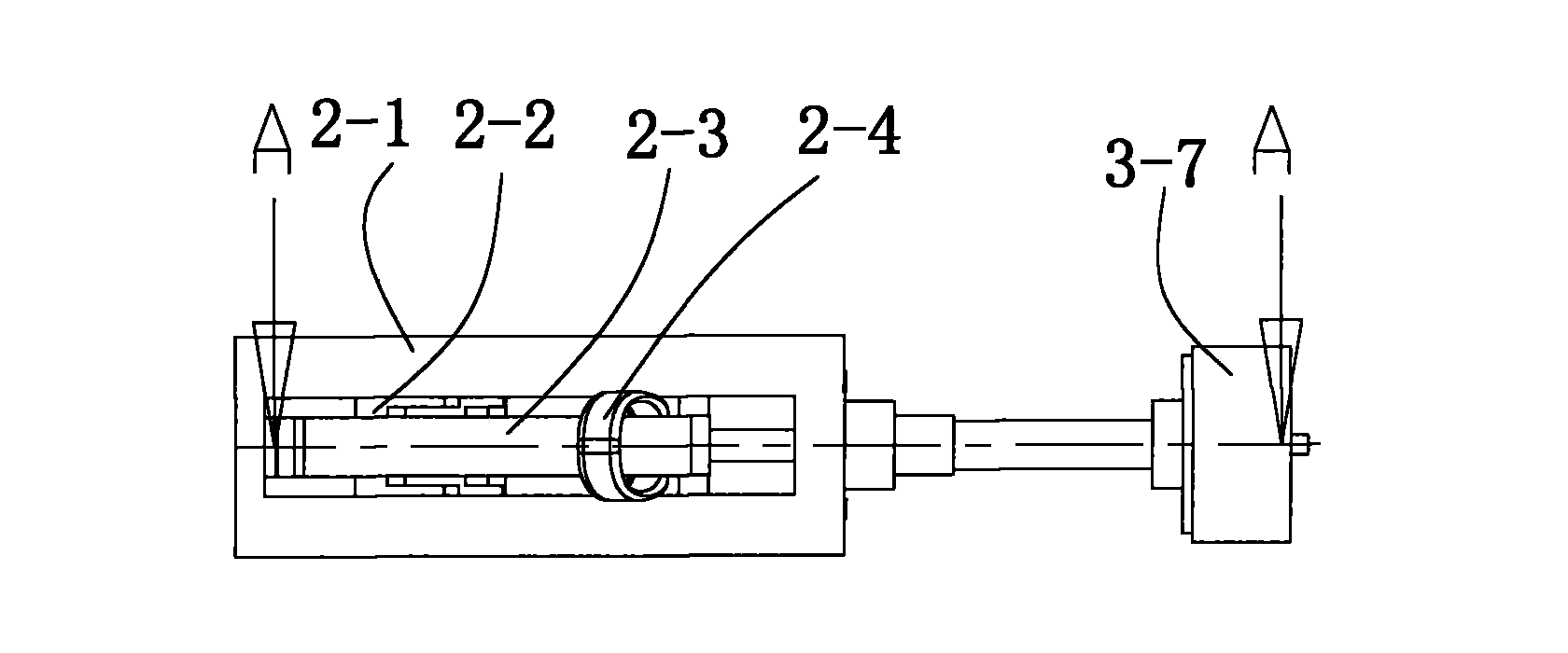

[0016] figure 2 It is a schematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com