Artificial muscle aggregation group

A technology of artificial muscles and muscles, applied in the field of artificial muscle assembly groups, to achieve the effect of ensuring the output quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] With reference to accompanying drawing, further illustrate the present invention:

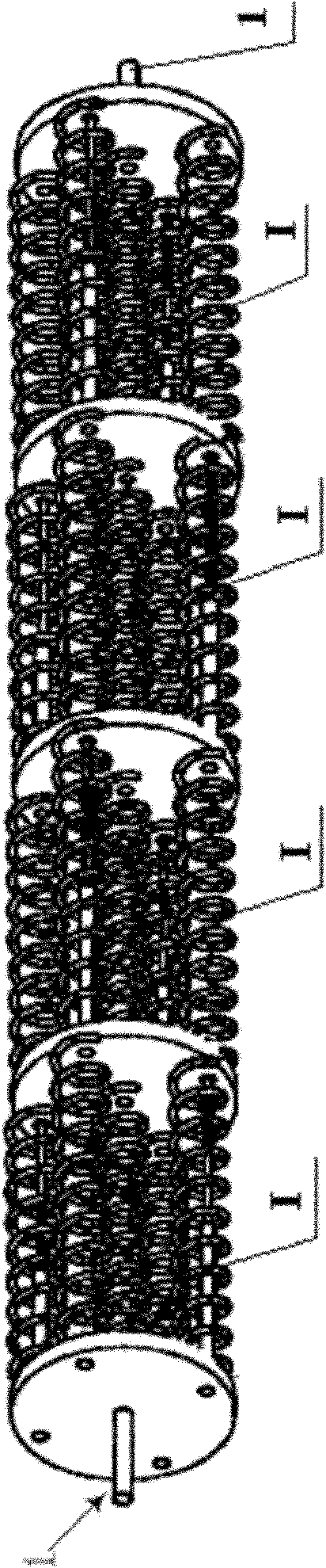

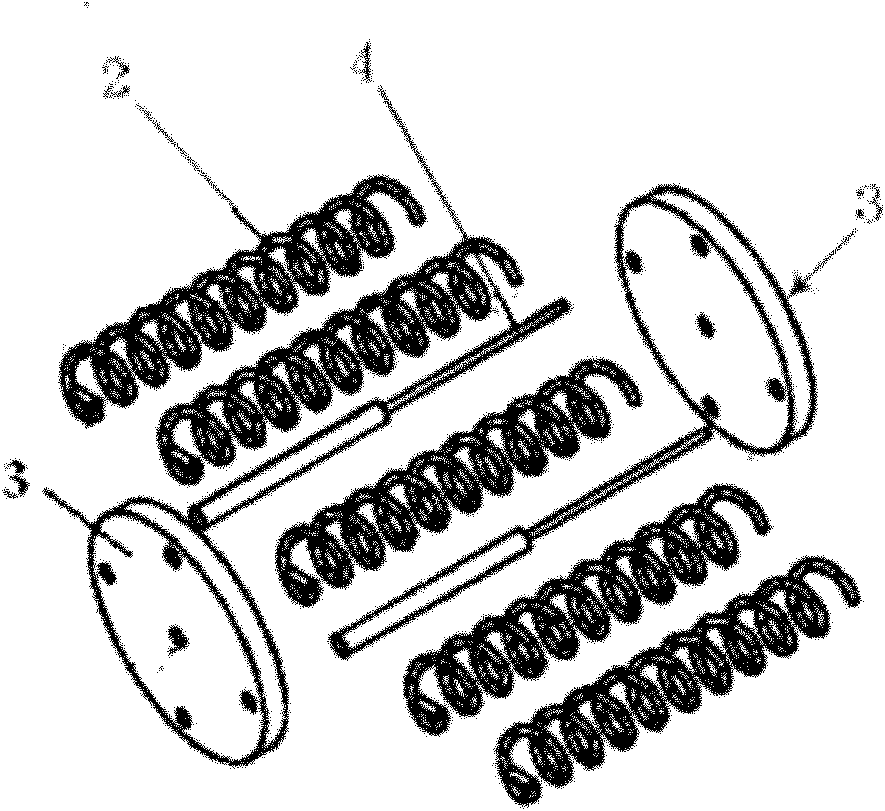

[0043]The artificial muscle assembly group is formed by a plurality of muscle units I connected in series, and the muscle unit I includes a plurality of springs 2 as artificial muscles, a front connection plate 31 and a rear connection plate 32 respectively fixed to the two ends of the spring 2, The springs 2 are evenly distributed along the surfaces of the connecting plates 31, 32, and each spring 2 is provided with a guiding-locking mechanism 4;

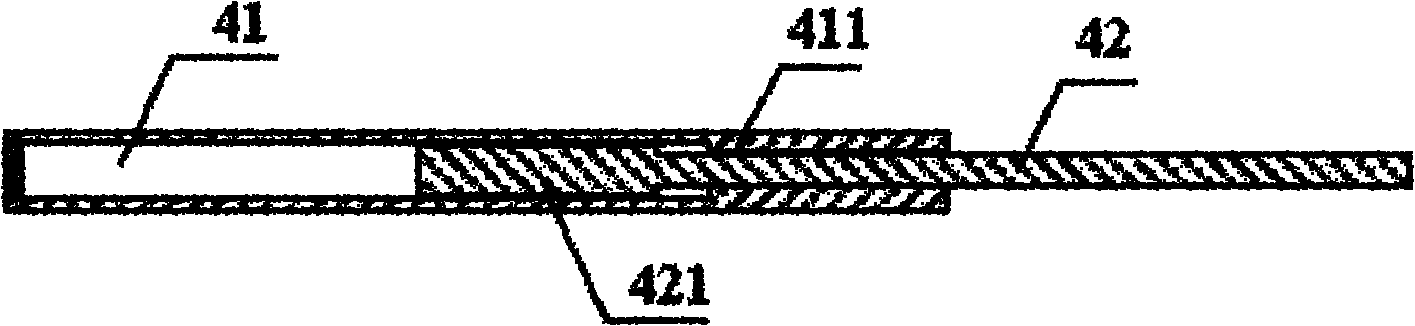

[0044] Both ends of the guide-lock mechanism 4 are fixedly connected to the front connecting plate 31 and the rear connecting plate 32 respectively, and the guide-lock mechanism 4 is slidably socketed by the sleeve 41 Composed of the piston 42 in the sleeve 41, one end of the piston 42 hidden in the sleeve is provided with a ring 421, and the end of the sleeve 41 that allows the piston 42 to be exposed is provided with a stop The protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com