Small flexible distributing/feeding manipulator

A manipulator and flexible technology, applied in the field of manipulators, can solve the problems of large manipulators, inconvenient installation of materials and feeding, inconvenient grasping of small parts, etc., and achieve the effect of fast and accurate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

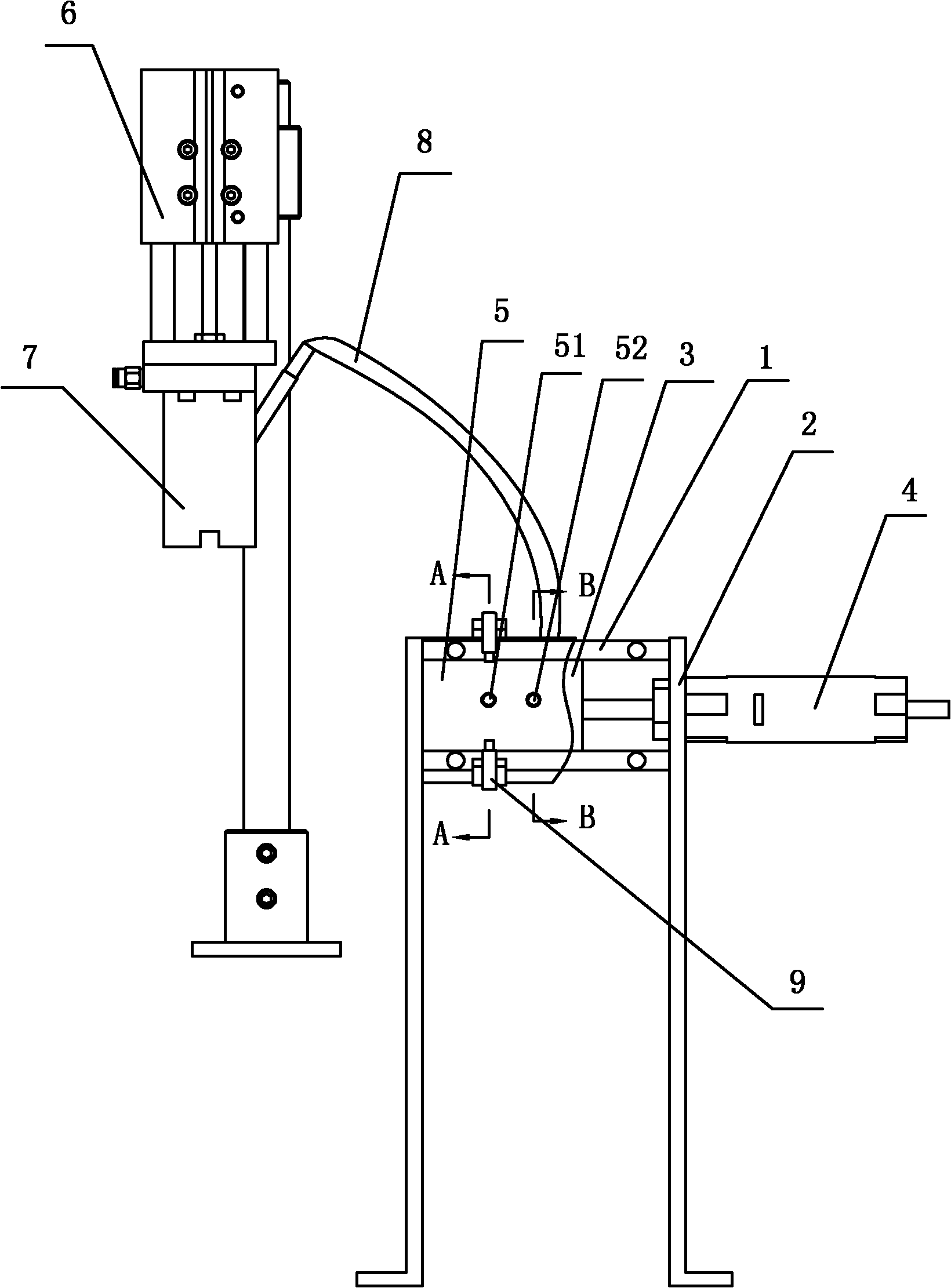

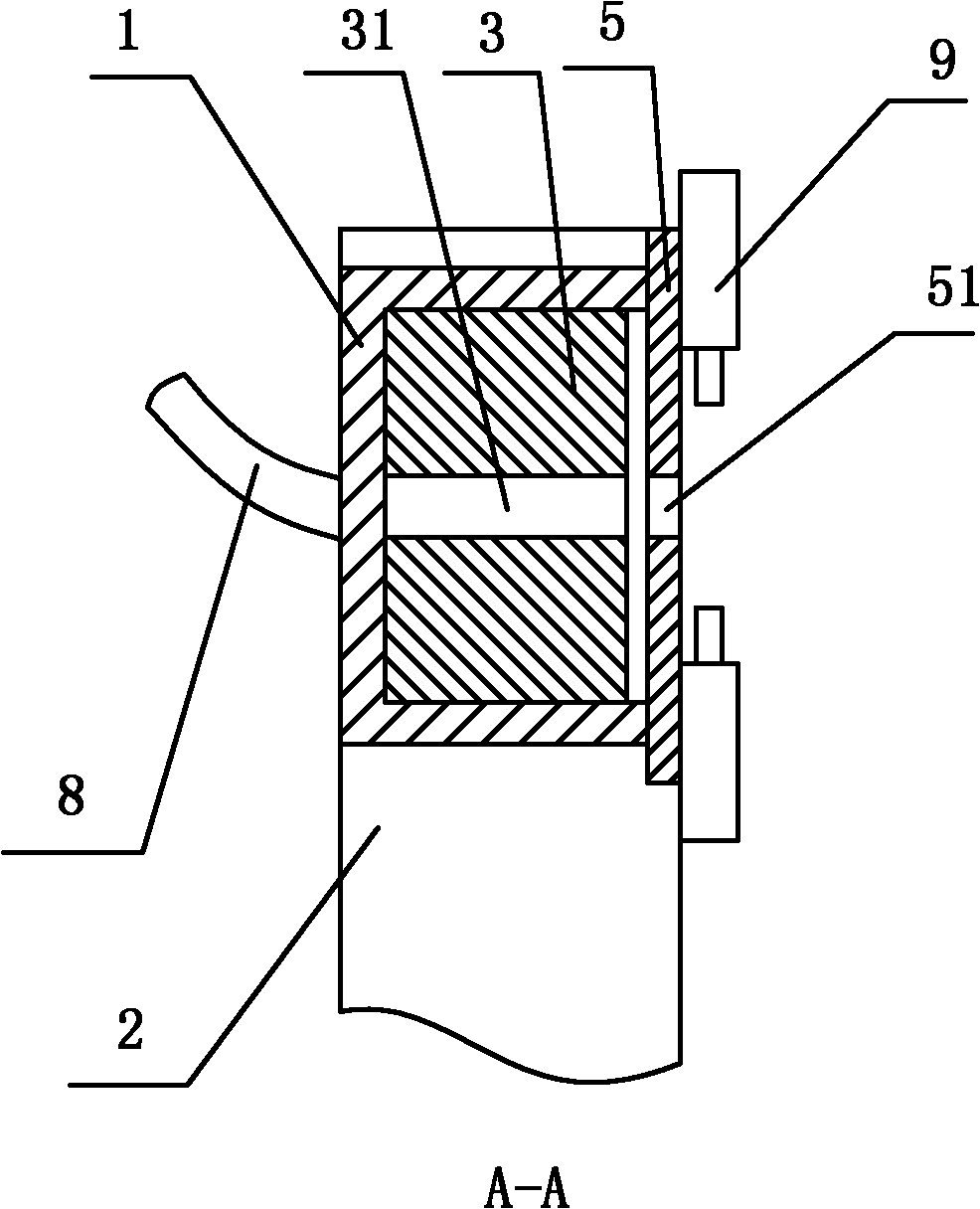

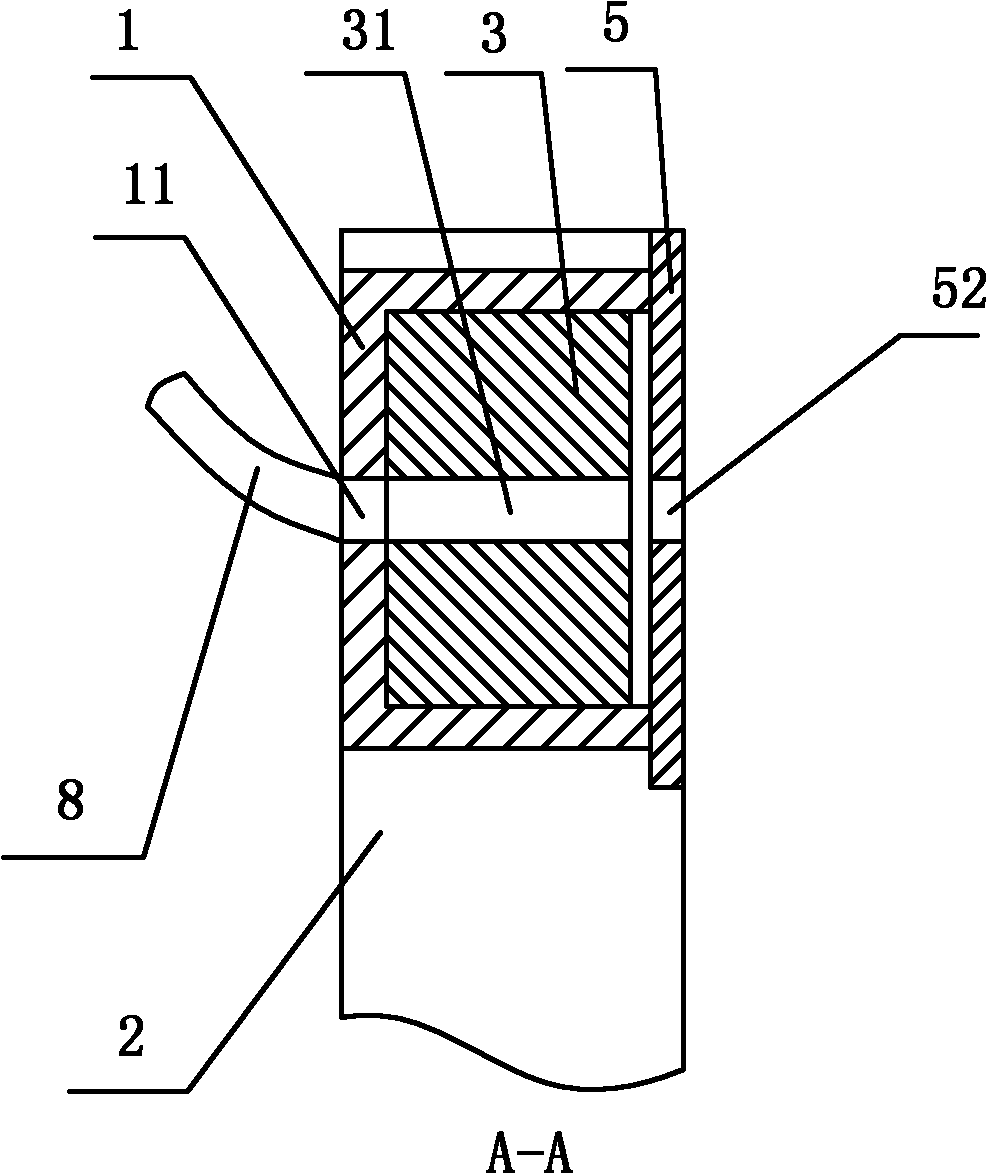

[0011] Such as figure 1 , figure 2 , image 3 As shown, a small-sized flexible material distribution and feeding manipulator includes a material distribution device and a feeding device. The material distribution device includes a chute 1 and brackets 2 fixed on both sides of the chute 1, and a slide block is arranged in the chute 1 3. One side of the slider 3 is connected to the cylinder rod of the double-acting single-rod cylinder 4, and the double-acting single-rod cylinder 4 is located outside the support 2, and an end cover 5 is also provided on the chute 1; A material storage hole 31 is provided, the material storage hole 31 is connected with the feeding device, the end cover 5 is respectively provided with a feeding hole 51 and an air inlet 52, the air inlet 52 is connected with the air supply device, and the chute 1 is provided with Discharge hole 11 is arranged, and described feed hole 51 is coaxial with material storage hole 31, and described air inlet 52 is coaxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com