Surfacing repair method for large cold-rolled supporting roll

A back-up roll, large-scale technology, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of high purchase cost, short service life, long manufacturing cycle of large-scale cold-rolled back-up rolls, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

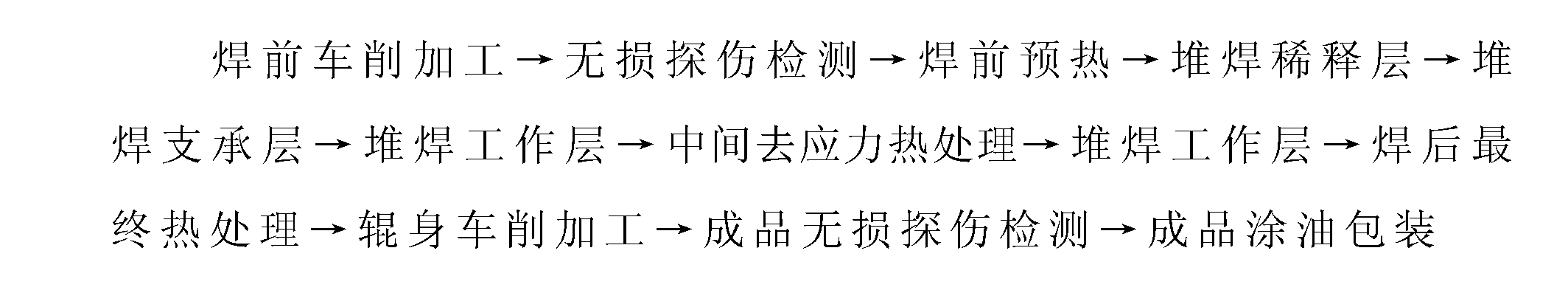

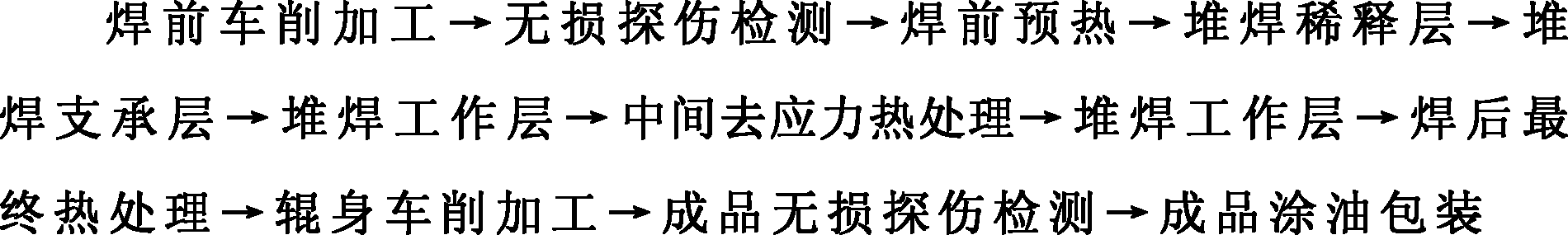

[0008] The surfacing welding repair method of the large-scale cold-rolling back-up roll of the present invention is described in conjunction with the accompanying drawings.

[0009] The surfacing welding repair method of large cold-rolled back-up roll of the present invention, this repair method comprises the following steps:

[0010] (1) Turning before welding

[0011] Remove the roll surface defects and fatigue layer of the back-up roll, and turn them to ensure the thickness of the surfacing layer. Partial defects on the roll surface are turned or partially ground with a grinder to ensure that all roll surface defects and fatigue layers are removed to make a spare roll Blank;

[0012] (2), non-destructive testing

[0013] Ultrasonic testing is carried out on the turned roll blank to check whether the fatigue layer is completely removed and whether there are internal crack defects in the roll body. If there are still defects, it is necessary to continue turning to eliminate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com