Structure-improved welding torch

A welding torch and welding wire tube technology, applied in the field of welding torches with improved structure, can solve the problems of reducing welding efficiency, prolonging welding time, stuck, etc., and achieving the effects of improving welding quality, shortening welding time and reducing fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

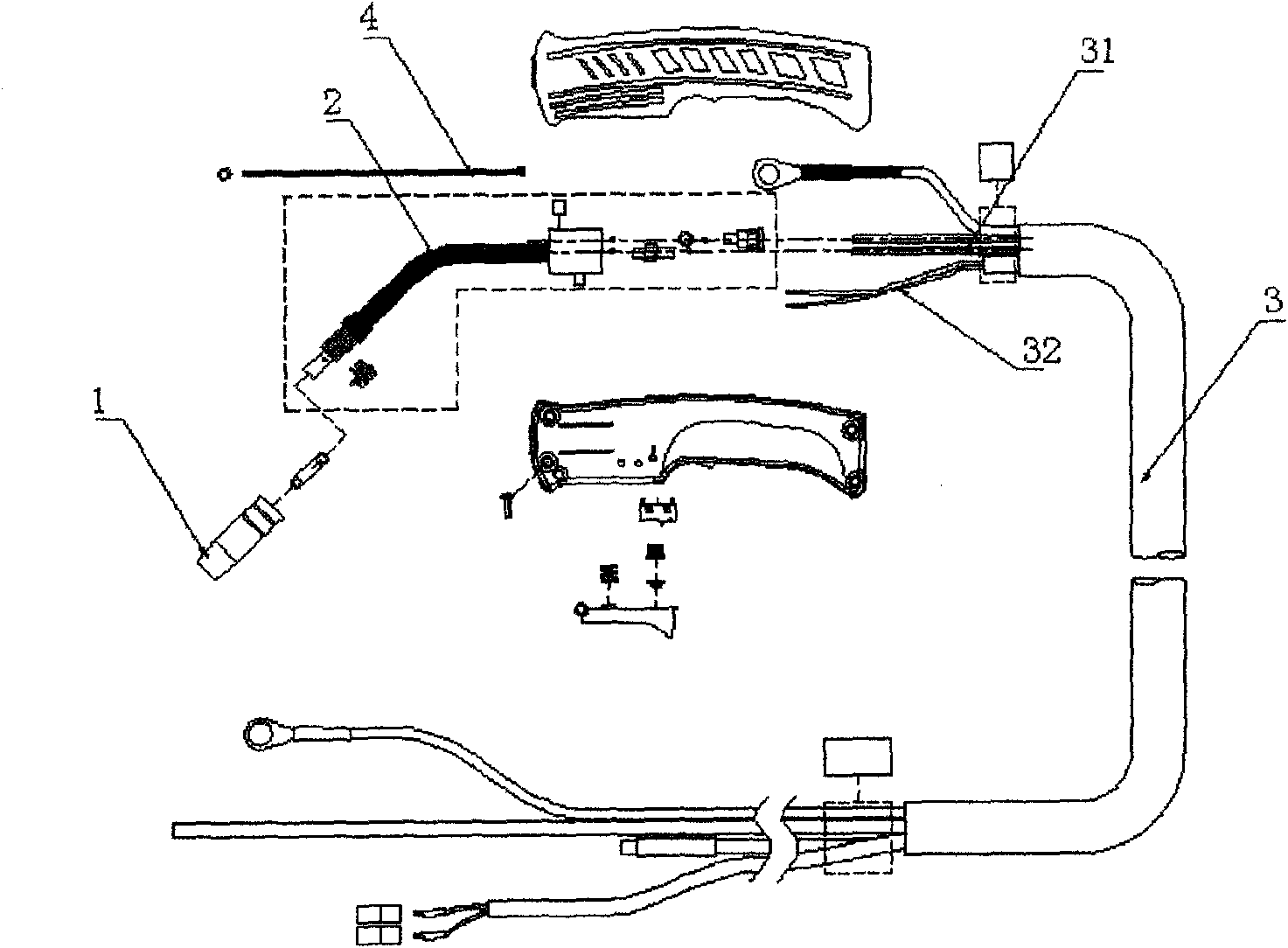

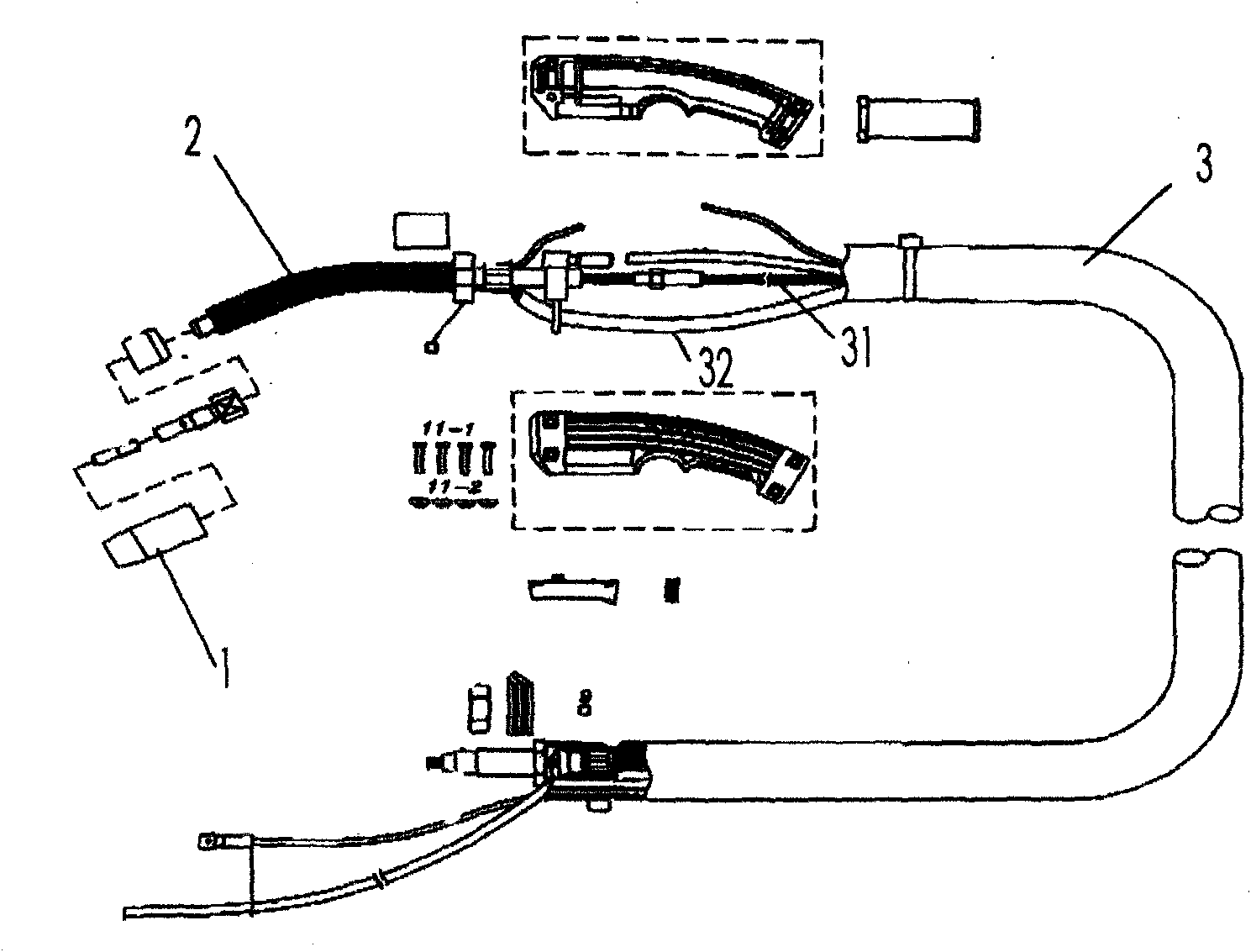

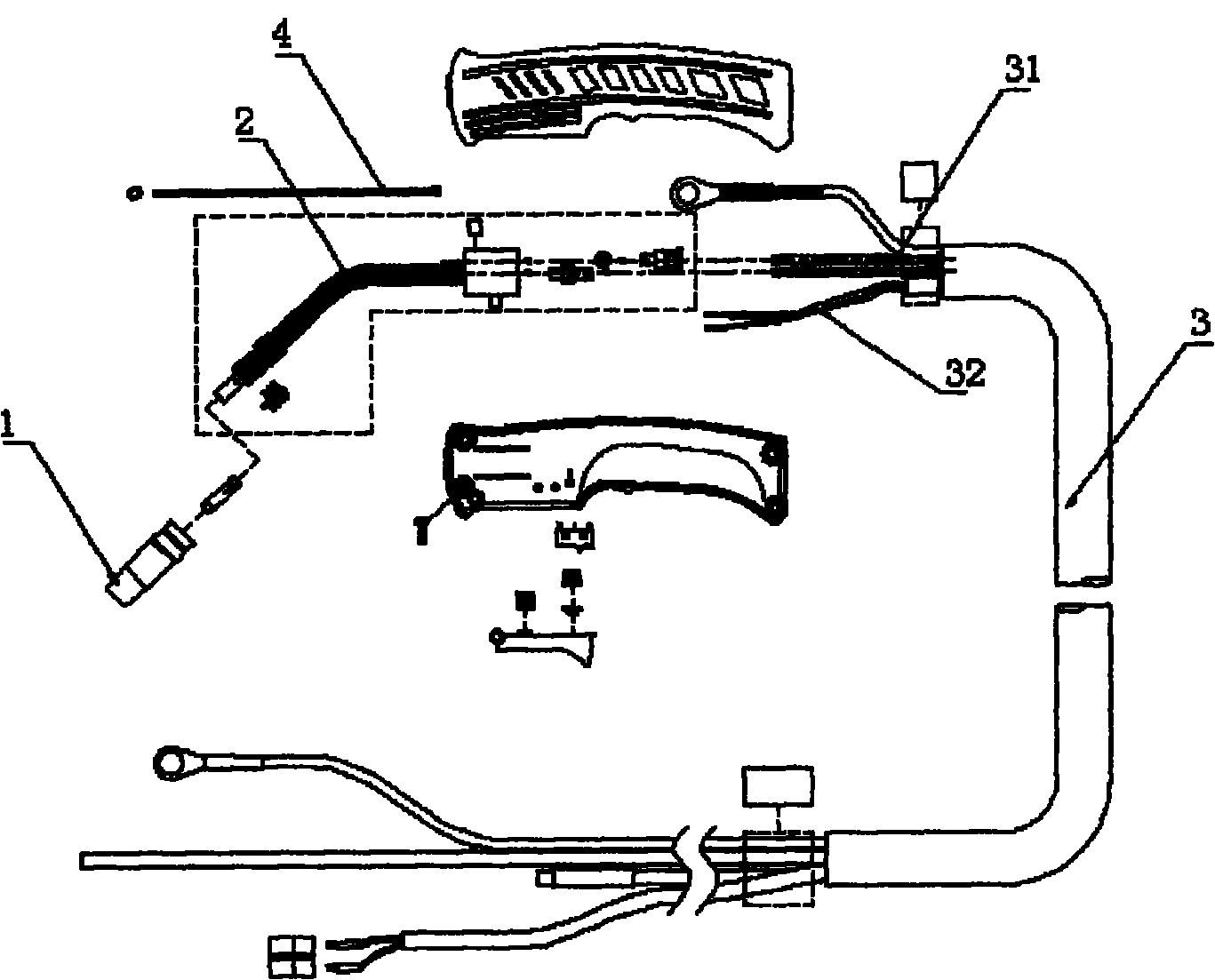

[0013] Embodiment: a welding torch with improved structure, including a burner 1, an elbow 2 and a cable sleeve 3, one end of the burner 1 communicates with the other end of the elbow 2 and is fixedly connected, and one end of the elbow 2 is fixedly connected with the cable sleeve 3 The cable casing 3 is provided with a welding wire pipe 31 and a cable group 32, and one end of the elbow 2 is fixed with a short conduit 4 in a hollow tubular body, and one end of the short conduit 4 communicates with the welding wire pipe 31 in the cable casing. The other end communicates with the inner cavity of the elbow 2. When the welding wire is fed into the elbow 2 in the welding wire tube 31, due to the guiding effect of the short conduit 4, the welding wire is fed smoothly and will not be stuck with the elbow 2, so that The welding gun is more convenient and comfortable to use, and the welding effect is better.

[0014] The short conduit 4 has elasticity, and the short conduit 4 can be fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com