Tensioning transmission shaft

A transmission shaft, expansion and tightening technology, applied in the direction of couplings, rigid shaft couplings, mechanical equipment, etc., can solve the problems of large assembly force, large knocking force in disassembly, inconvenient disassembly and assembly, etc., to improve the transmission force. , to ensure the coaxiality, the effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

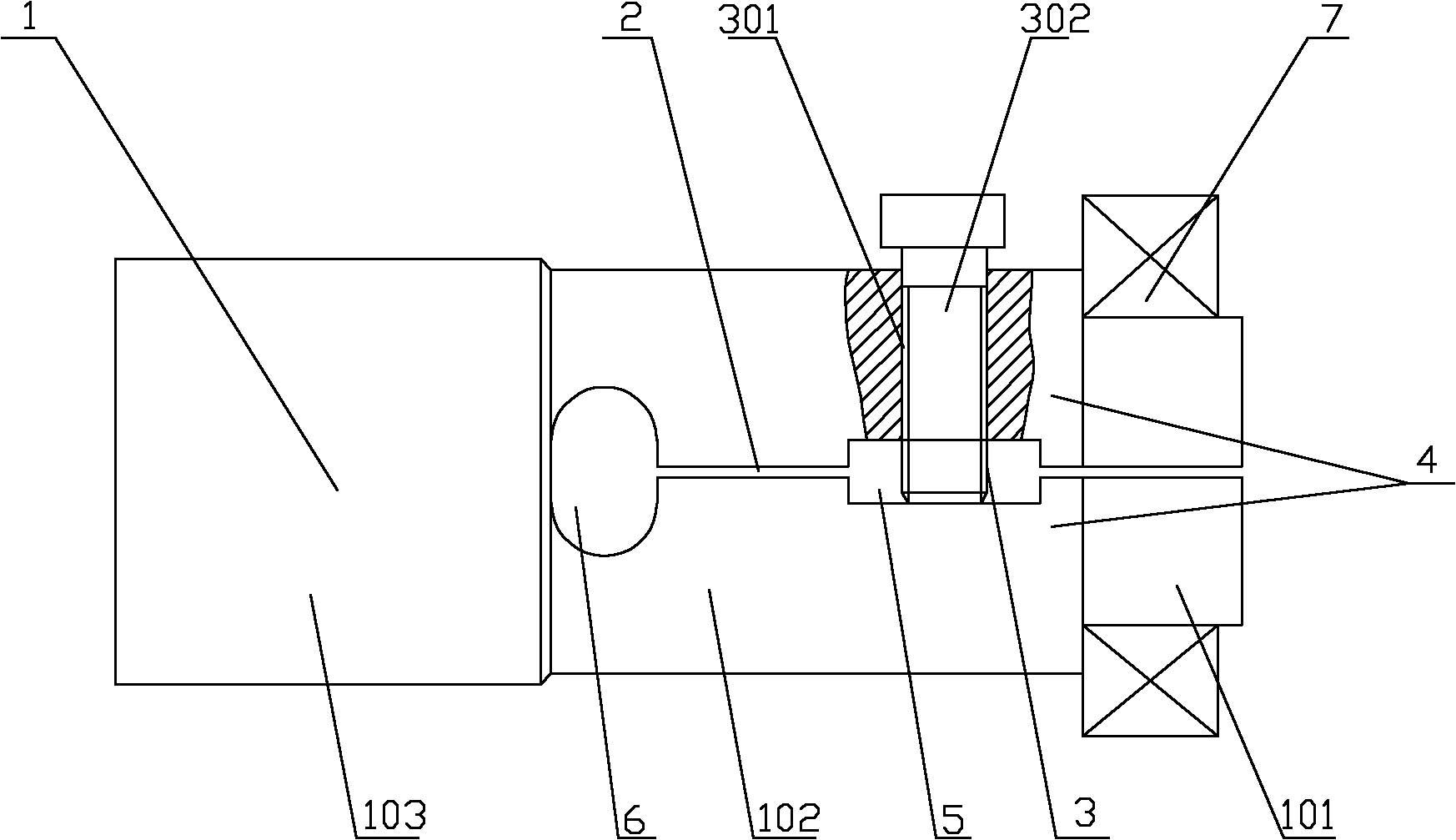

[0015] Such as figure 1 , figure 2 As shown, a tension transmission shaft includes a shaft body 1, one end of the shaft body 1 is cut along its axis direction with a 0.18mm molybdenum wire to form a gap 2, and the gap 2 can divide the end of the shaft body 1 into two forks The bifurcated part 4, the slit 2 passes through the shaft center, and the bifurcated part 4 is provided with an expansion device 3 for expanding it to fit with the fitting.

[0016] The expansion device 3 includes a threaded hole 301 which is arranged on one of the forks of the bifurcation part 4 and communicates with the seam 2. The screw 302 is installed in the threaded hole 301, and the bifurcation part 4 can be rotated by rotating the screw 302. Expand, so that the shaft body 1 and the fitting 7 are closely matched.

[0017] The shaft body 1 is a stepped shaft, including a first-level shaft 101 , a second-level shaft 102 and a third-level shaft 103 . The steps of the shaft can position the fitting 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com