Movable device for testing state of blowing mold

A technology of blow molding molds and inspection devices, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc. It can solve the problems of verification status molds not being verified in time, troublesome mold replacement, and extended debugging time, so as to prevent clogging and Sand leakage, easy to drain, improve the effect of sand dredging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

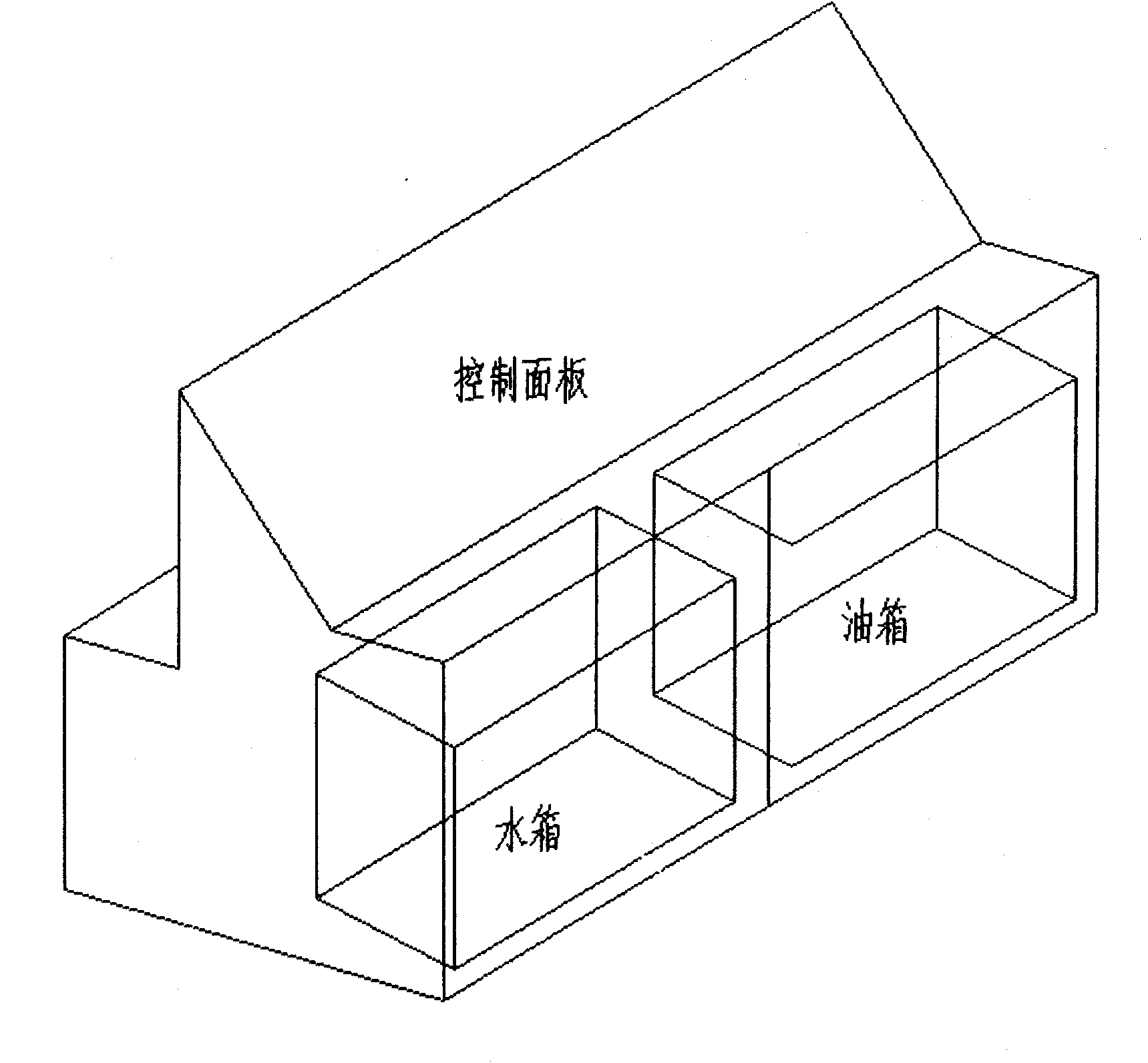

[0022] In the following, a mobile blow mold state inspection device of the present invention will be further described in detail with reference to the accompanying drawings and specific embodiments.

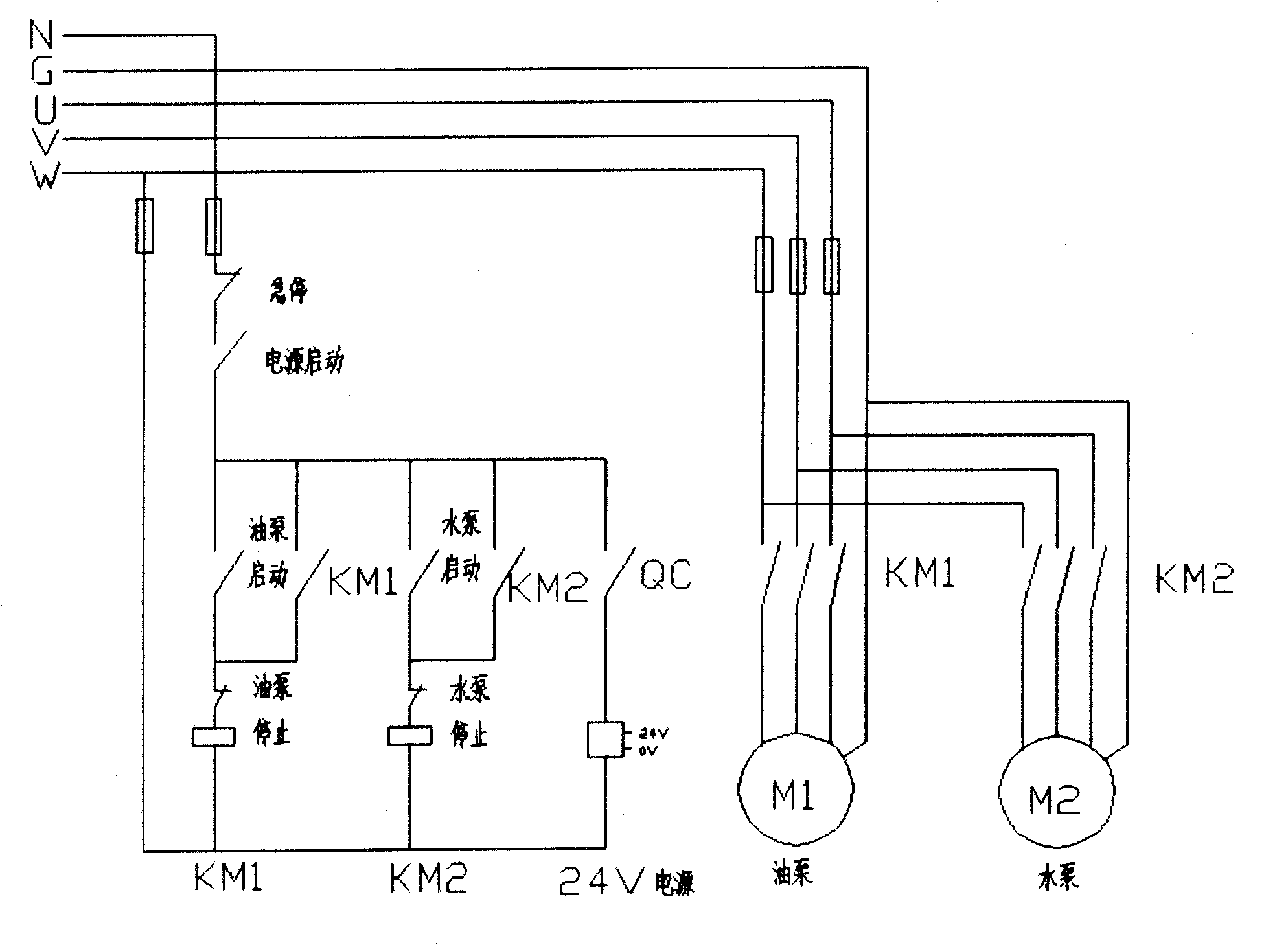

[0023] According to the figure, the inspection device of the present invention includes a main circuit, a control circuit and a hydraulic circuit.

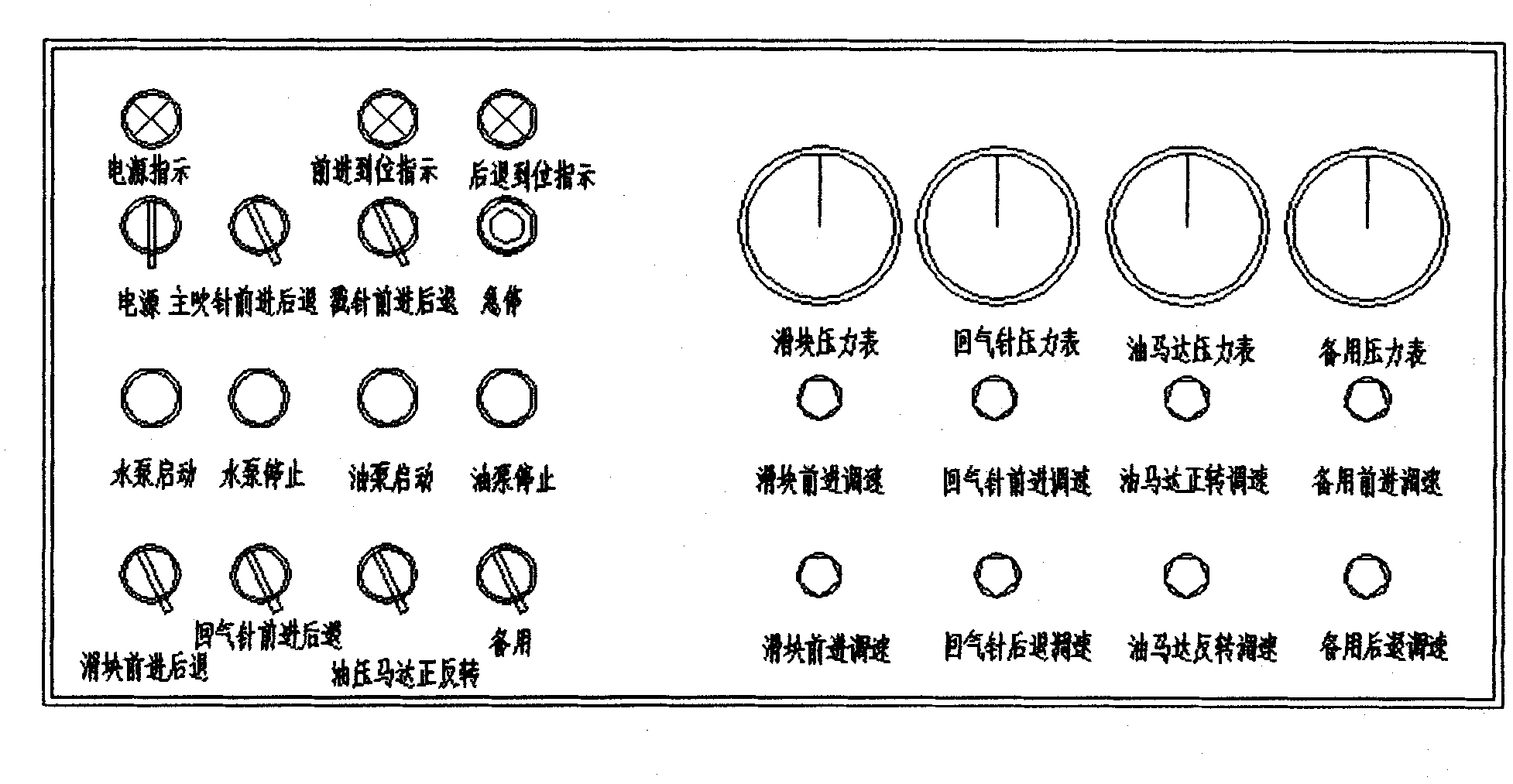

[0024] The high-pressure gas used by the device is externally connected through the pipeline. Connect each oil circuit, gas circuit, and water circuit of the device with the pipeline that the mold needs to detect, and control the corresponding control on the control panel to detect whether the mold's various action states are normal.

[0025] As shown in the figure, turn on the power switch, the power indicator will light up, turn on the oil pump, water pump, and 24V power supply in turn. If the hydraulic motor is operated on the control panel to rotate forward, the corresponding solenoid valve will act, and the intermediate relay will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com