Floor heating thermostatic valve

A thermostatic valve and floor heating technology, which is applied in valve details, valve devices, valve operation/release devices, etc., can solve the problems that temperature control valves cannot adjust the set temperature value, cannot apply water floor heating systems, etc., and achieve a wide range of applications , high operational safety, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

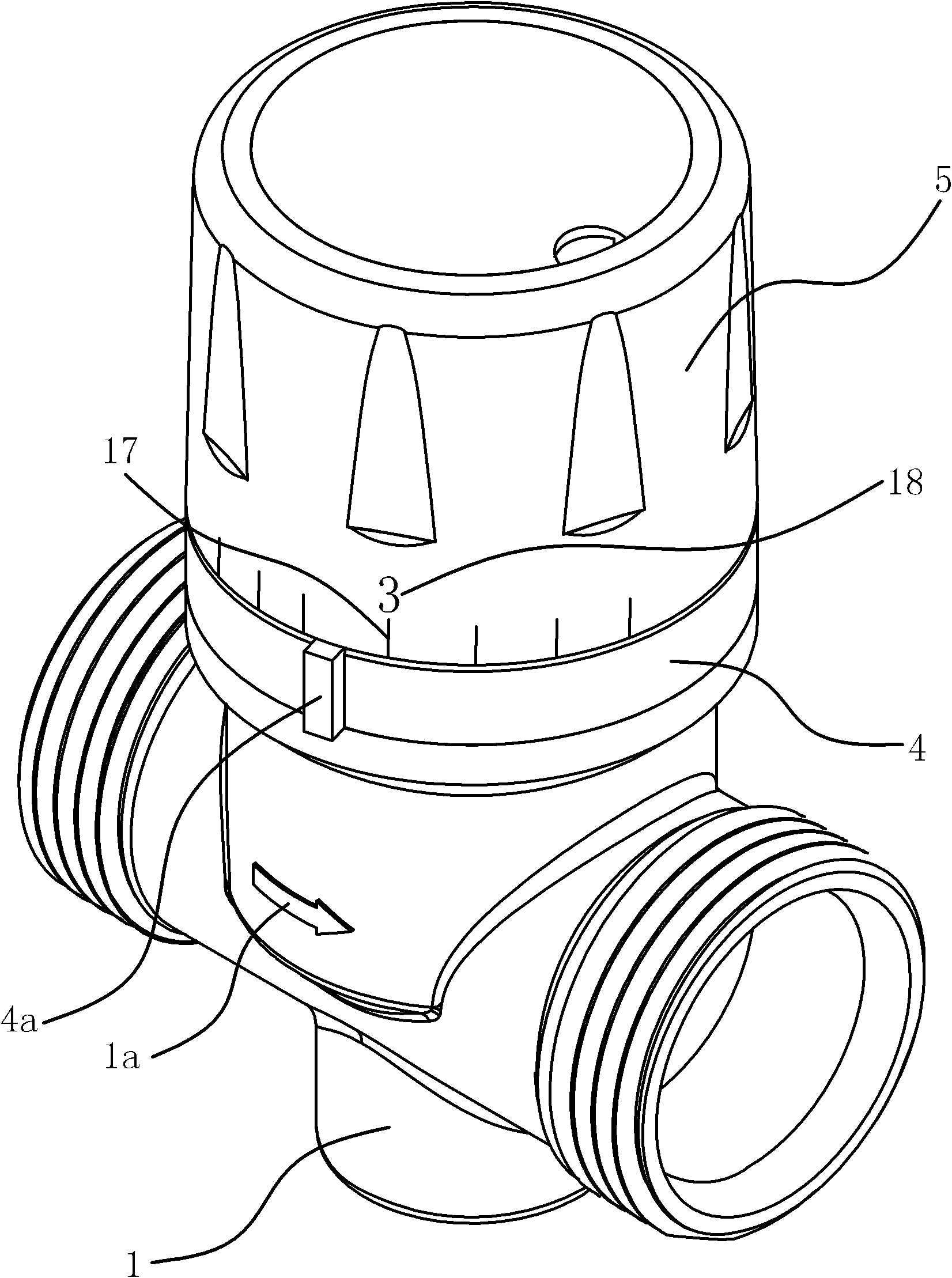

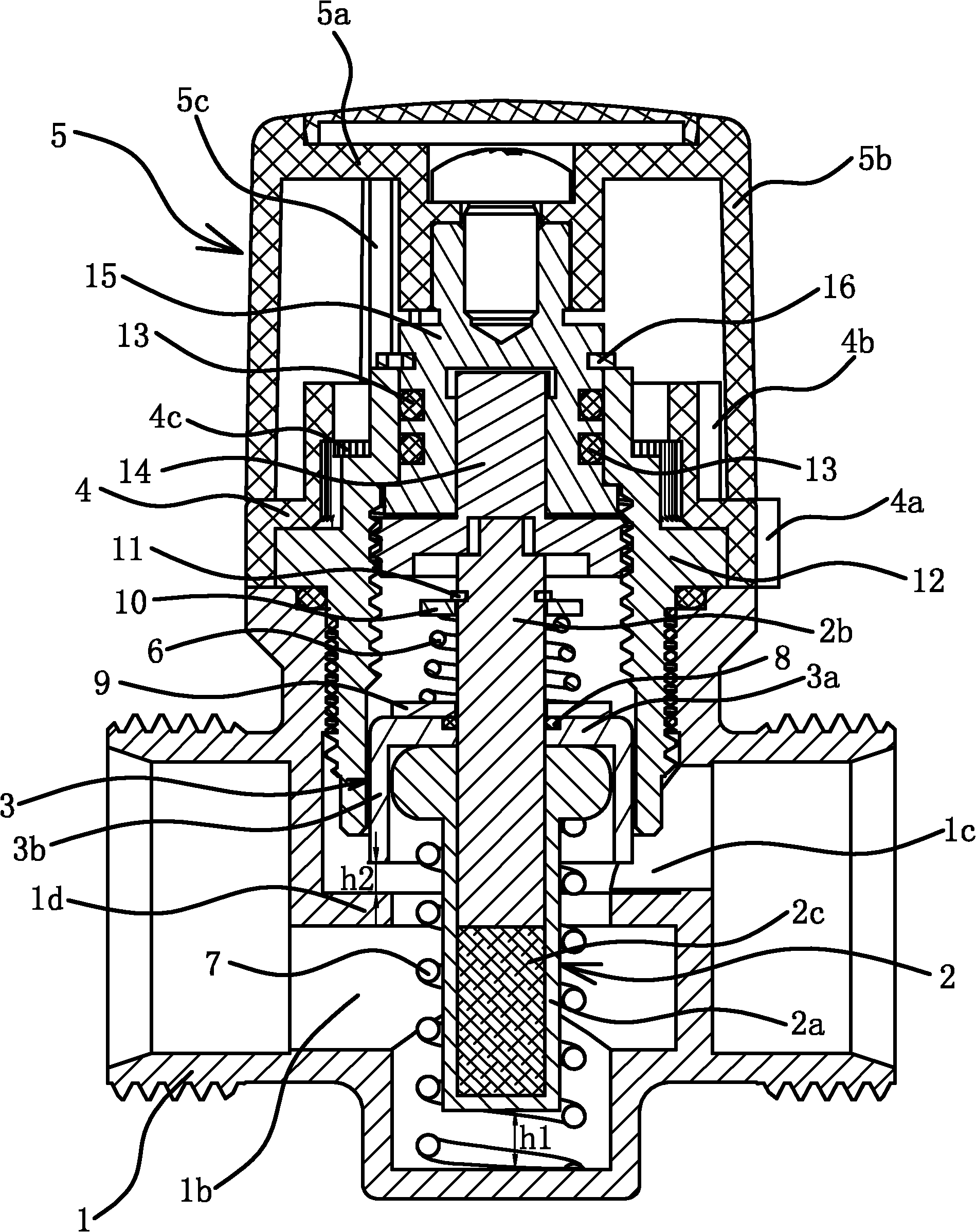

[0036] Such as Figure 1 to Figure 4 As shown, the local heating thermostatic valve includes a valve body 1, a temperature bulb 2, a valve core 3, a spring one 6, a spring two 7 and an adjustment mechanism.

[0037] Specifically, the valve body 1 has a sealing portion 1d inside, and further divides the inner chamber of the valve body 1 into a water inlet chamber 1b and a water outlet chamber 1c. On the outer wall of the valve body 1 there is an arrow 1a marking the direction of water flow.

[0038] The temperature bulb 2 includes a body 2a, a push rod 2b pierced on the body 2a, and a temperature-sensing medium 2c arranged in the body 2a. The inner end of the push rod 2b can abut against the temperature-sensing medium 2c, and the outer end passes through the body 2a. The temperature bulb 2 belongs to the prior art, and will not be described in detail here. The body 2a of the temperature bulb 2 is located in the water inlet chamber 1b, and the ejector rod 2b penetrates into t...

Embodiment 2

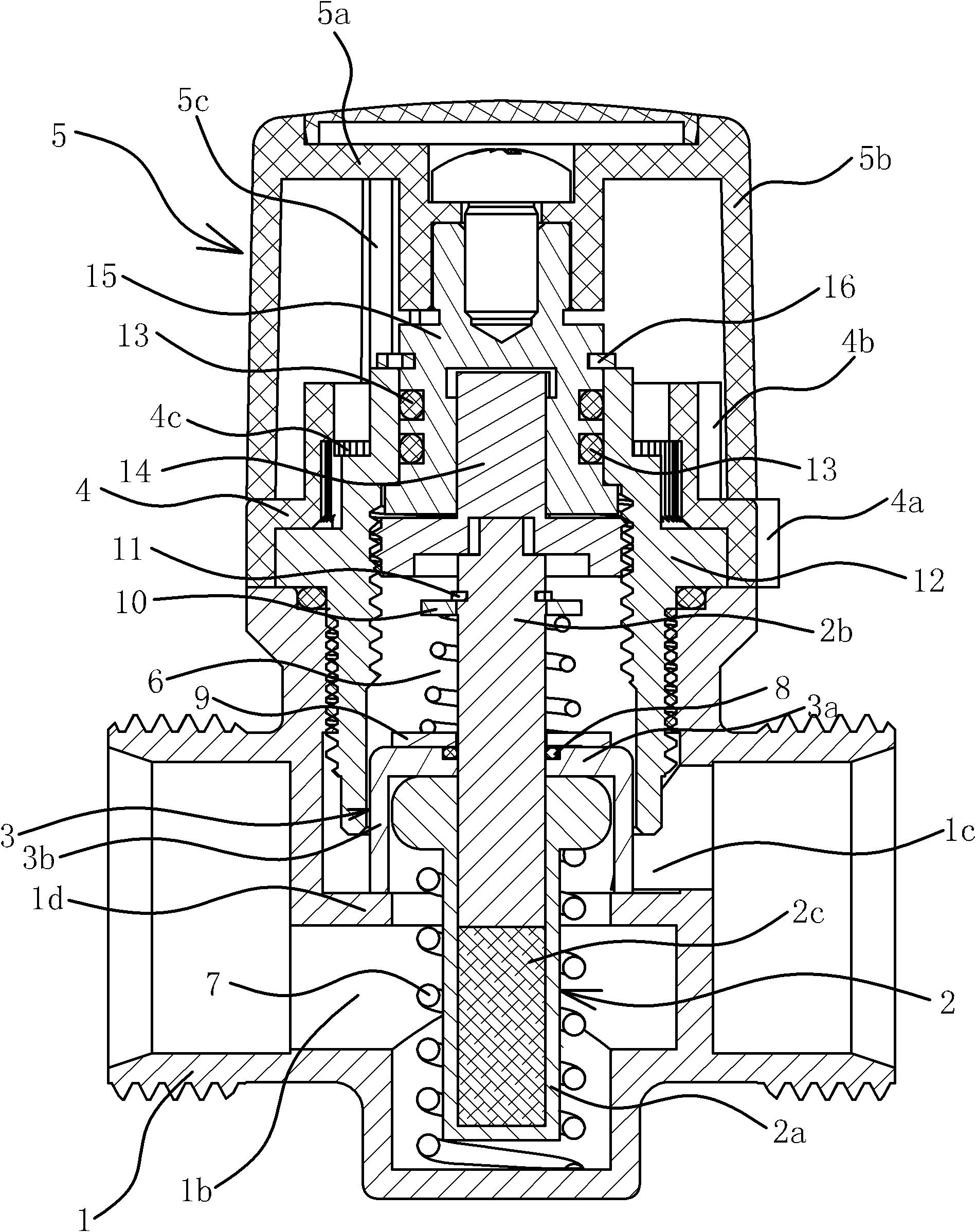

[0055] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference is that the valve core 3 is located in the water inlet chamber 1b and the valve core 3 is fixedly connected with the outer end of the ejector rod 2b of the temperature bulb 2 . The spool 3 is disc-shaped and the remaining push rods 2b are connected as a whole. A bottom cover 19 is fixedly connected to the side wall of the water inlet chamber 1b of the valve body 1, and a top cover 12 is fixedly connected to the side wall of the water outlet chamber 1c of the valve body 1. One end of the spring one 6 is in contact with the valve core 3, and the other end is in contact with the valve core 3. The top cover 12 leans against each other; one end of the spring 2 7 leans against the body 2 a of the temperature bulb 2 , and the other end leans against the bottom cover 19 .

[0056] The top cover 12 is provided with a lift screw 15 and a lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com