Device for paving tunnel waterproof boards

A tunnel waterproofing board and equipment technology, which is applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of low construction quality, high labor intensity and high labor intensity in laying waterproof boards, and achieve improved construction efficiency and low construction environment requirements , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

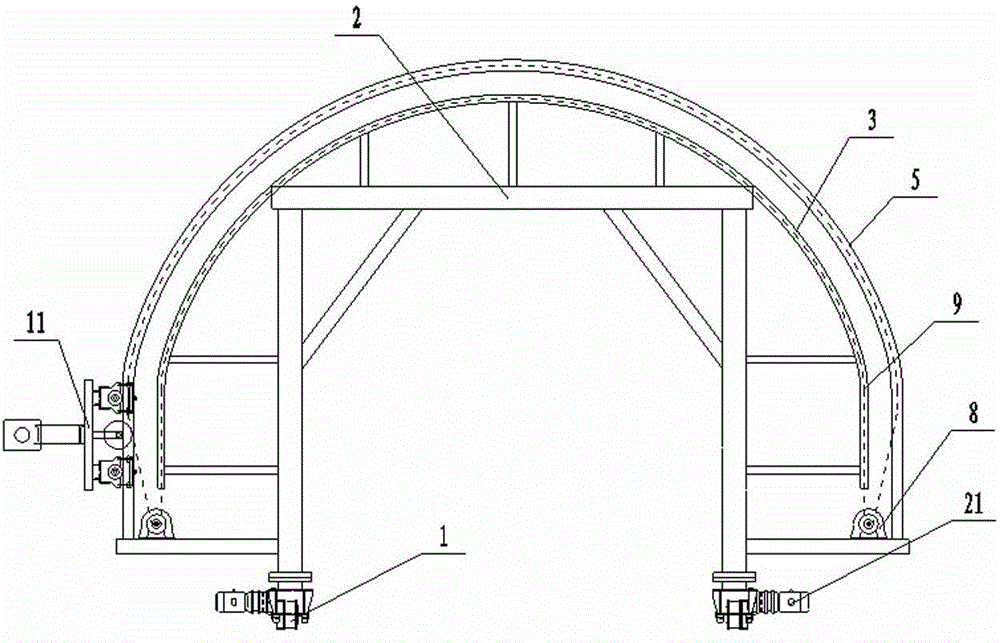

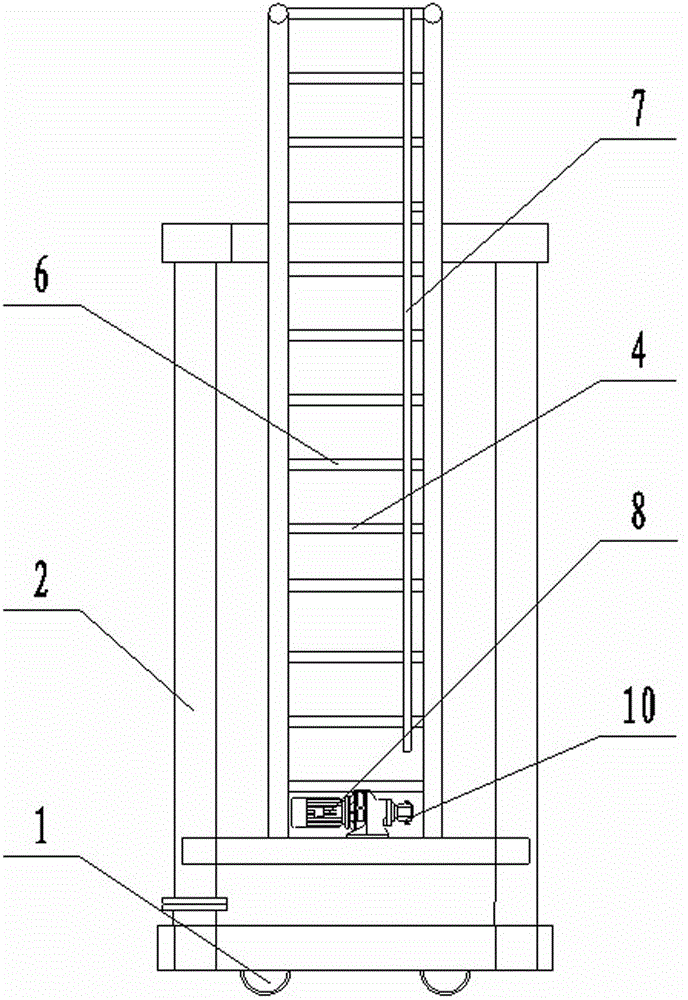

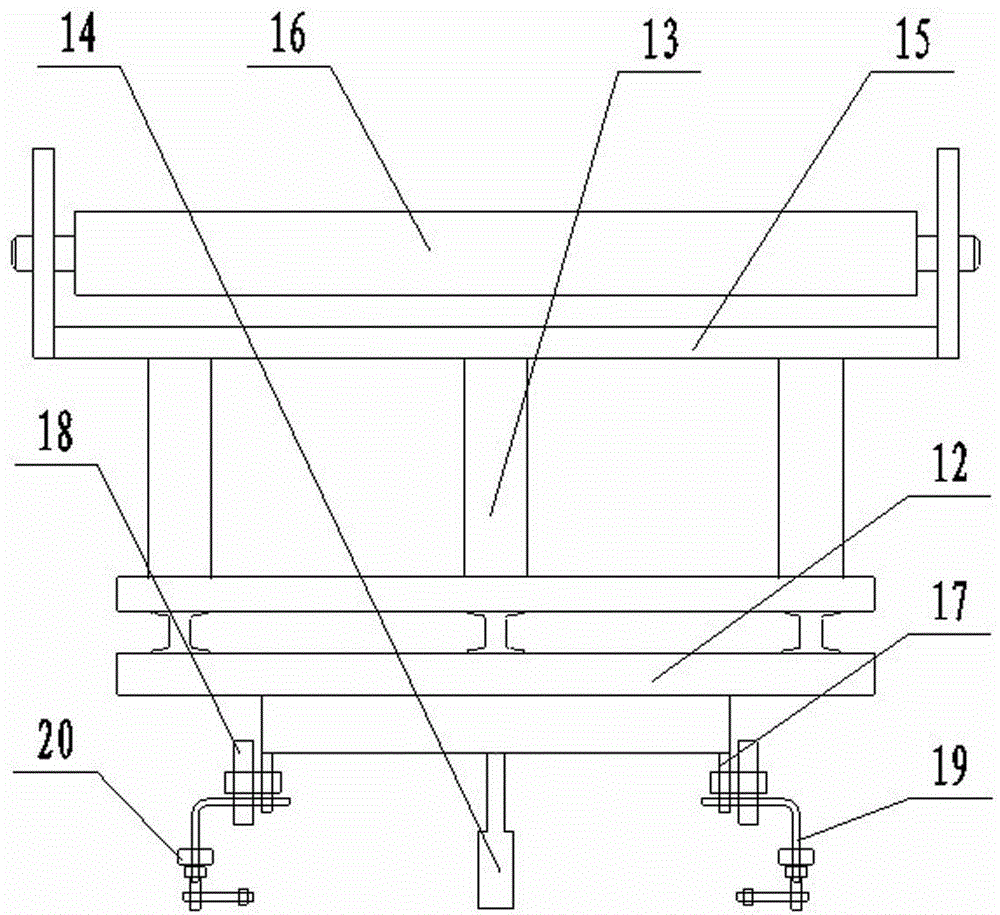

[0012] Tunnel waterproof board laying equipment, including a portal steel frame 2 with a walking wheel 1 at the bottom, two arc-shaped support rods 3 parallel to each other and distributed front and back are externally connected to the portal steel frame 2, and a A number of reinforcing rods 4 perpendicular to it, and above the two supporting rods 3 are provided with two parallel arc-shaped guide tubes 5 fixed to the portal steel frame 2, and a number of ribs perpendicular to them are fixed between the two guide tubes 5 6. A strip chain box 7 corresponding to the position in the front and rear directions is respectively fixed on the tendon bar 6 and the reinforcement bar 4. A motor 8 fixed to the door-type steel frame 2 is provided under the support bar 3. Two chain boxes 7 and the motor 8 A closed chain 9 is externally connected between them, and the output shaft of the motor 8 is provided with a power gear 10 meshing with the chain 9, and the guide tube 5 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com