Control method for thermal deformation compensation of ram of numerical control machine and device for implementing same

A technology of numerical control machine tools and control methods, which is applied in the direction of manufacturing tools, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of long time from warming up to thermal steady state, difficulty in controlling the expansion and contraction of rams, etc., and achieve good economy Benefits and social benefits, the effect of reducing processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

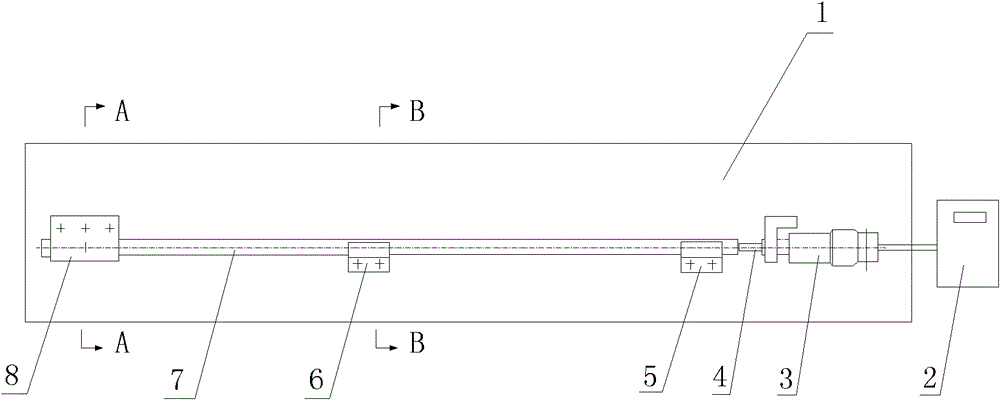

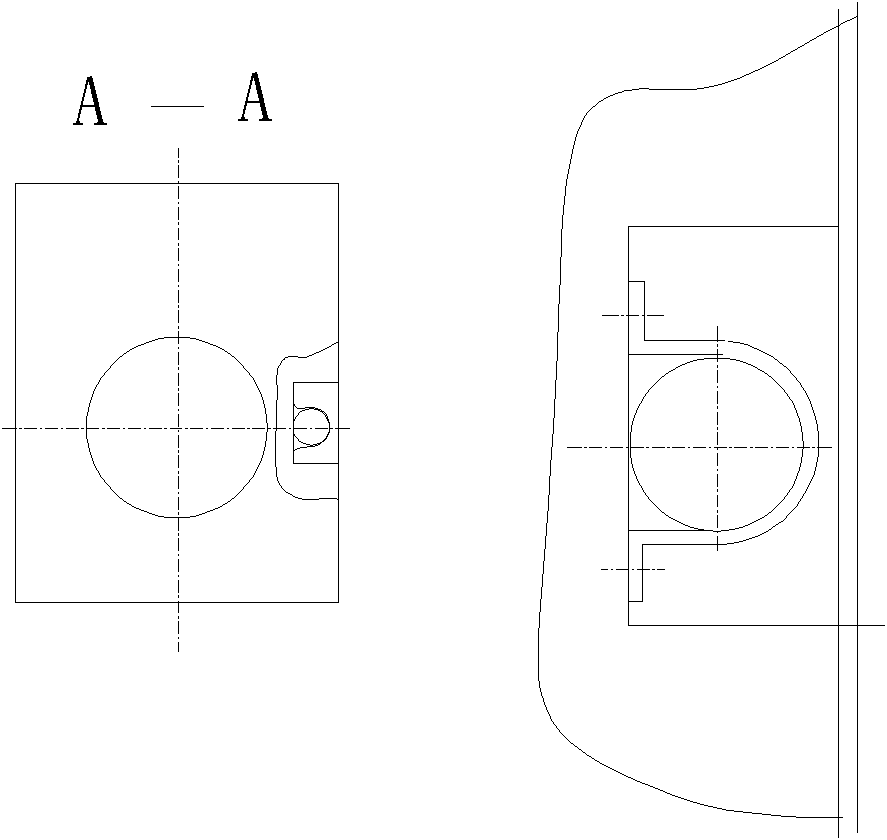

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] When the method described in the present invention is implemented, it needs to call the micro-motion analysis function of the hand-held unit in the CNC machine tool control system to complete it, for example, the micro-motion analysis function in the Siemens 840D numerical control system, that is, the DRF function. The micro-movement analysis function is to make the machine tool produce an additional incremental zero offset by relying on the action of the handwheel pulse when the machine tool is working in "AUTO" mode, so as to realize the purpose of real-time control of the machine tool movement. The method proposed in the present invention is to pass the thermal expansion and contraction deformation of the ram obtained by the micro-displacement sensing device in real time through the handwheel interface to the numerical control system as the zero offset, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com