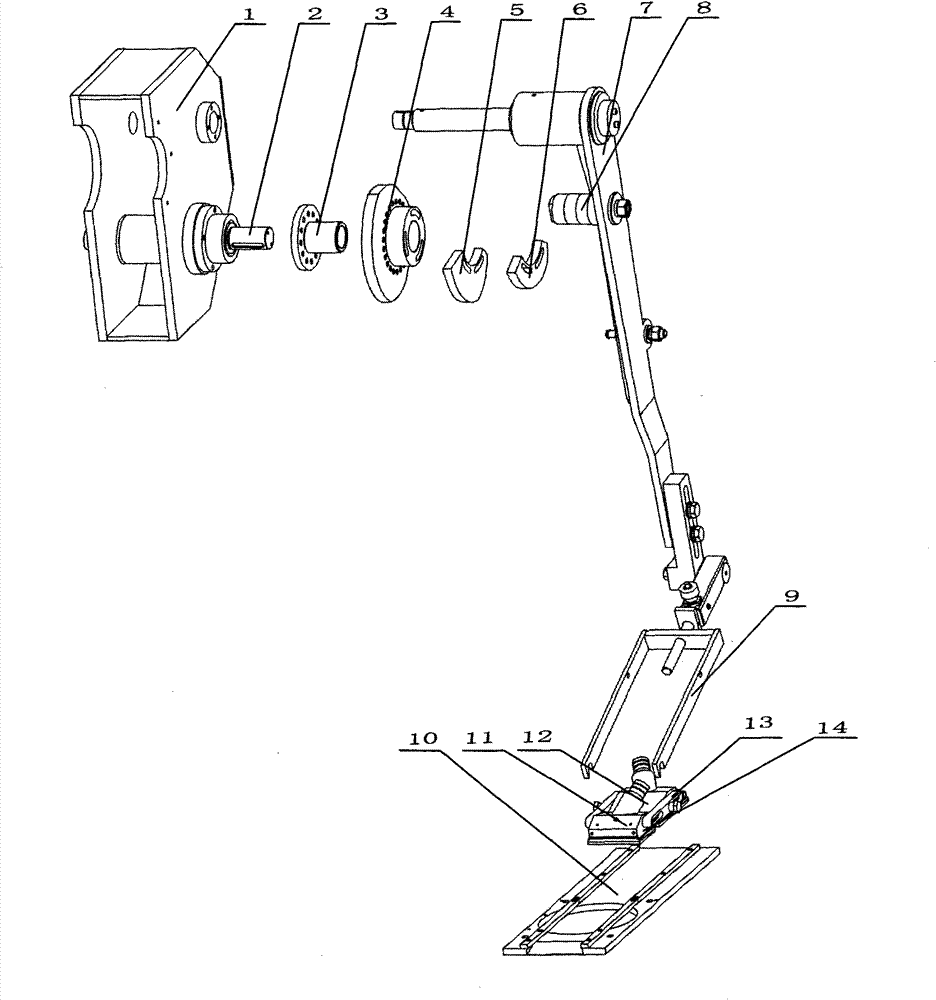

Multilayer powder-feeding device for powder forming machines

A technology of powder feeding device and forming machine, which is applied to presses, manufacturing tools, etc., can solve the problems of insufficient powder feeding time or pause time, the influence of the smooth completion of powder loading, and difficulty in controlling the pause position, so as to achieve the powder feeding pause time. Concrete, easy to assemble, good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

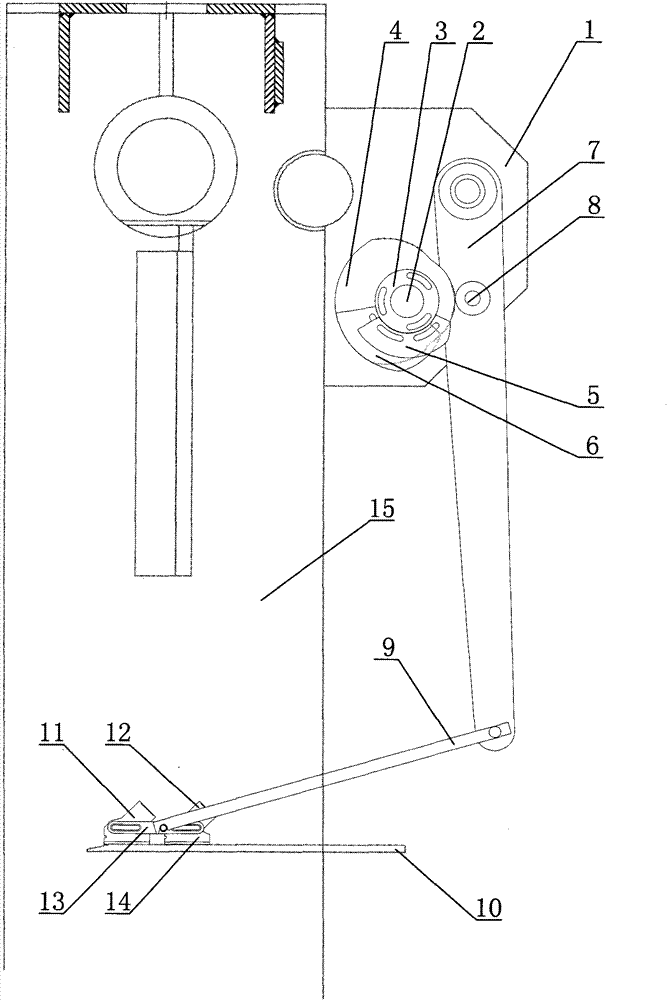

[0013] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

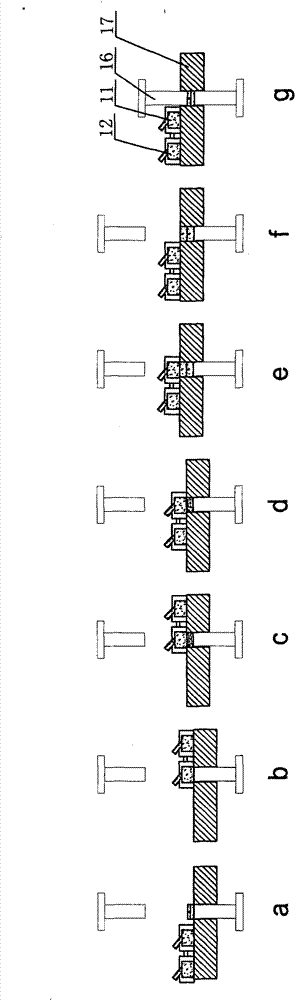

[0014] There is a through hole in the middle of the cam seat 4, and there is an adjustment installation hole on one end surface. The periphery of the end surface is designed as a smooth transition curve according to the requirements of powder feeding distance, powder feeding speed and multiple stop times. The other end has a waist-shaped adjustment. Cylindrical shape of the hole.

[0015] The cam piece first 5 and the cam piece second 6 are arcs with a waist-shaped adjustment hole respectively, and the periphery is also designed into different curves of smooth transition according to the design requirements. The cam sheet can be composed of multiple sheets of different shapes as required.

[0016] The cam base 4 is fixed on the camshaft 3, the cam piece A 5 and the cam piece B 6 are respectively clamped on the cam base, and fixed on the end face of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com