Method for testing pumpability of concrete mixture

A test method and concrete technology, applied in the direction of material inspection products, measuring devices, instruments, etc., can solve the problems of concrete bleeding, insufficient evidence, dry concrete, etc., and achieve the effect of improving work efficiency and avoiding blockage of pump pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A kind of concrete mixture pumpability test method of the present invention is based on conventional detection concrete mixture slump, slump spread etc., considering that the pumpability of concrete is closely related to the rich filling mortar content in concrete Therefore, a more convenient test method "filling mortar rich content method" is provided. The method of the present invention combines the slump test method of the concrete mixture to quickly evaluate the pumpability of the concrete mixture;

[0042] The concrete test method step of the inventive method is:

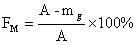

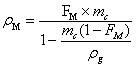

[0043] 1) Test and calculate the total content of mortar in concrete and mortar density ;

[0044] Take more than 20kg of representative concrete mixture, and weigh 10.0kg after mixing evenly. Use a square hole sieve to sieve out the stones above 4.75mm, and weigh the weight of the sieved stones in mg; the mesh size of the square hole sieve is selected according to the particle size of the stones in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com