Mechanical swivel joint seal device

A technology of rotary joints and sealing devices, which is applied to the sealing of engines, mechanical equipment, engine components, etc., can solve problems such as easy vibration and noise, speed limitation, and gaps in coordination, and achieve simple and easy technical means and increase operating speed , the effect of small dynamic interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

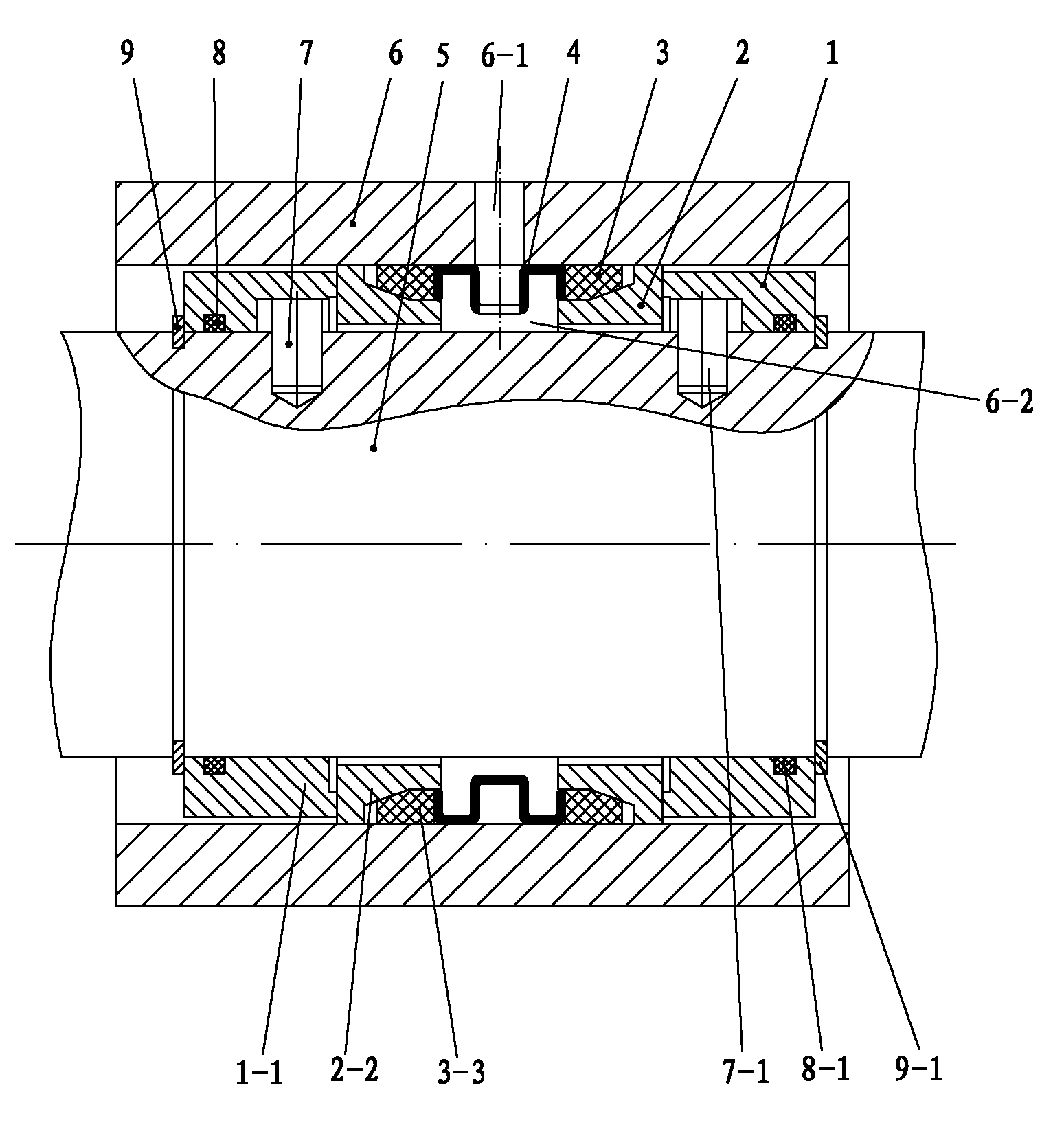

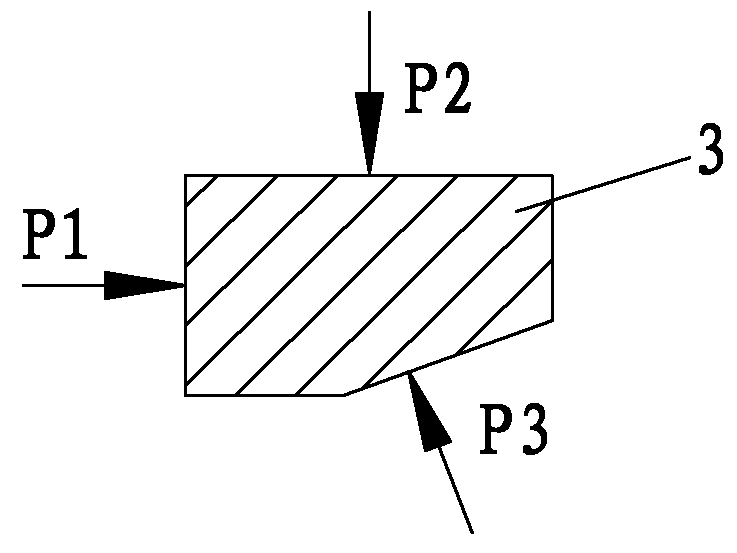

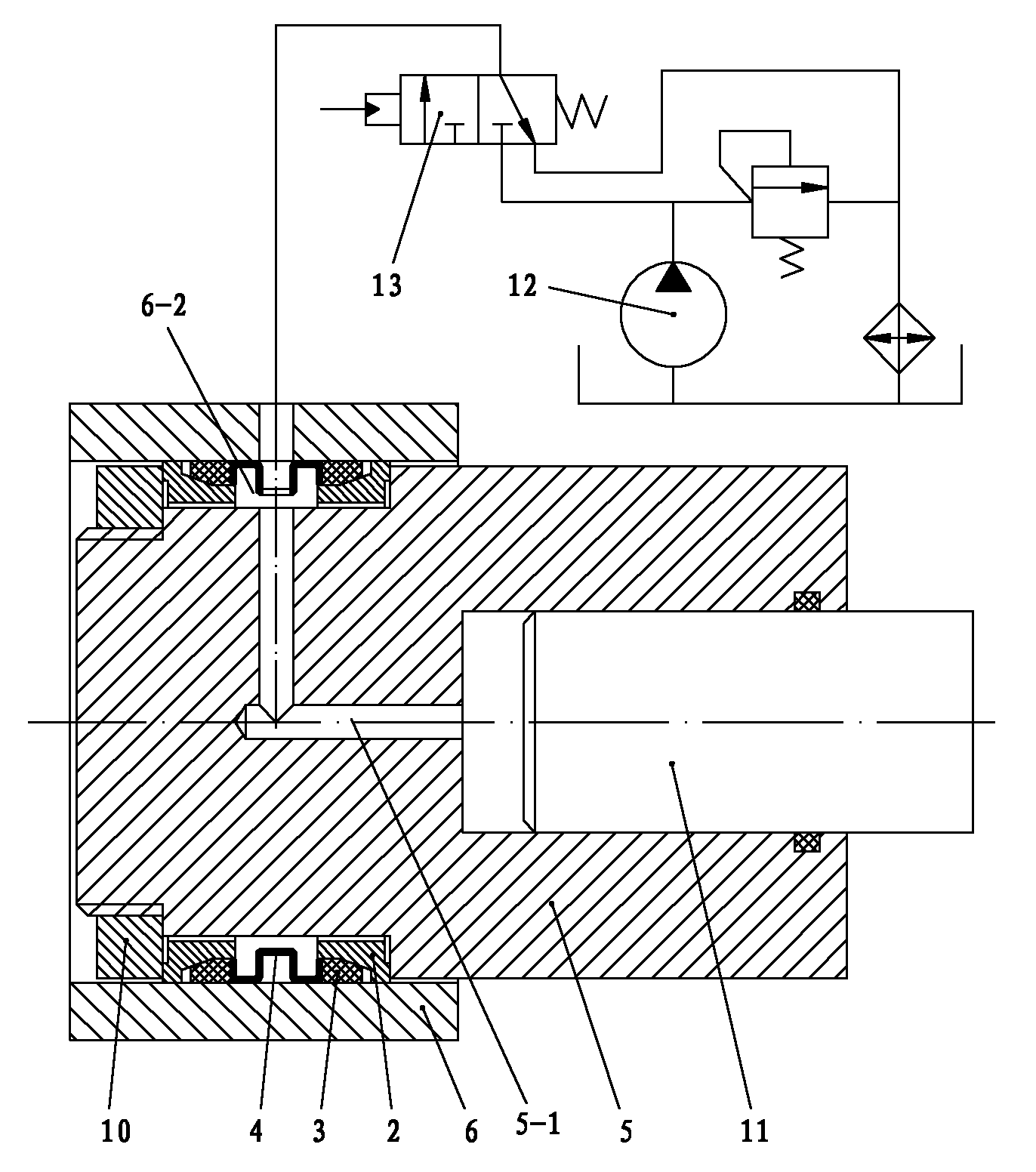

[0031] Such as figure 1 As shown, the mechanical rotary joint sealing device of the present invention is embedded between the shaft 5 and the housing 6 and seals the fluid between the housing 6 and the shaft 5. It has two moving rings 1, 1-1, Two static rings 2, 2-2, two rubber rings 3, 3-3, and a spacer sleeve 4; the moving rings 1, 1-1 are respectively located at the outermost ends of the shaft 5 and are sealed and fixedly connected with the shaft 5; The static rings 2, 2-2 are respectively located inside the moving rings 1, 1-1, and their outer end faces contact the inner end faces of the moving rings 1, 1-1 to form a sealing friction pair; the rubber rings 3, 3-3 are respectively sleeved On the static ring 2, 2-2, its outer circle fits with the inner circle of the shell 6, and the inner circle of the rubber ring 3, 3-3 is matched with the outer cone of the static ring 2, 2-2; the elastic spacer 4 is located In the sealed cavity 6-2 formed between the rubber rings 3 and 3-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com