Cutting device

A technology of cutting device and cutting table, which is applied in metal processing and other directions, and can solve problems such as inability to cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The best examples for carrying out the invention are shown below. The scope of the present invention should be interpreted in consideration of the possibility of changes based on known techniques in the description of claims.

[0051] 【Example】

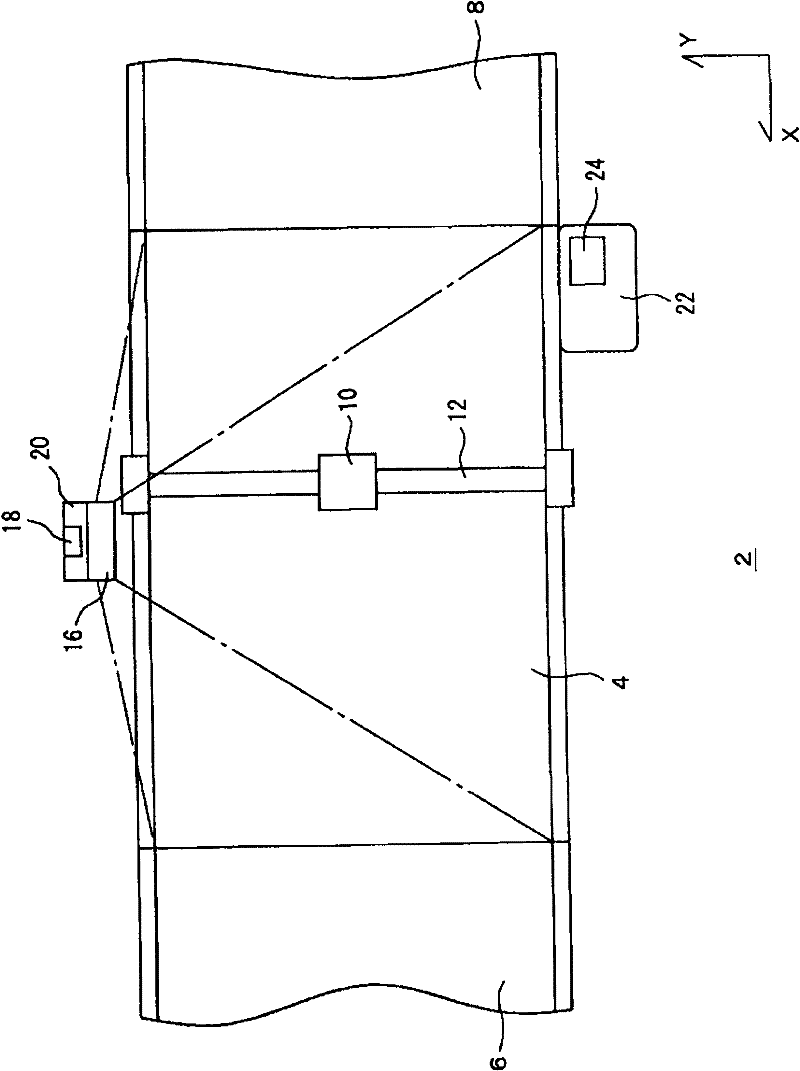

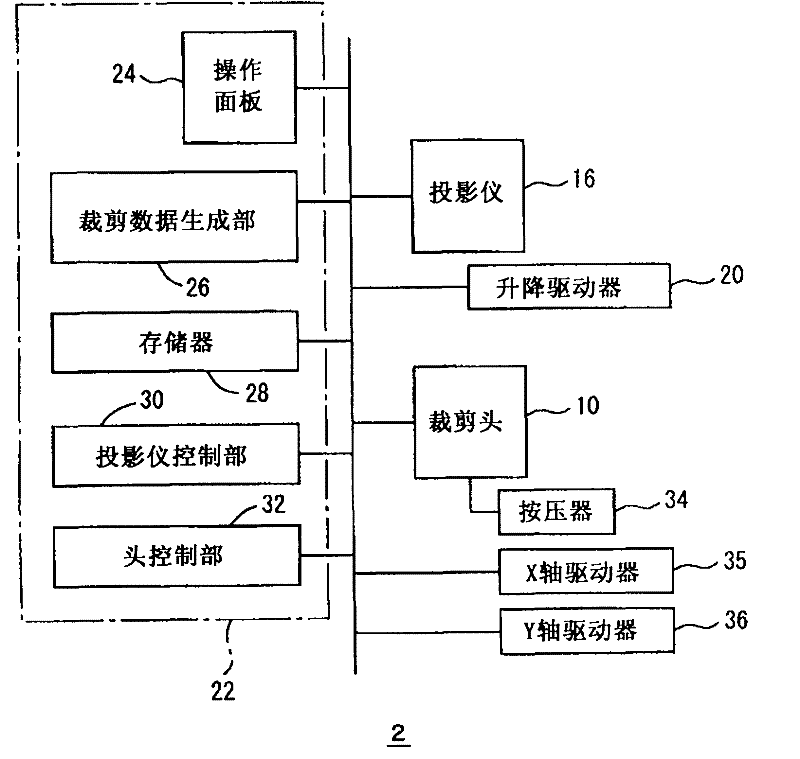

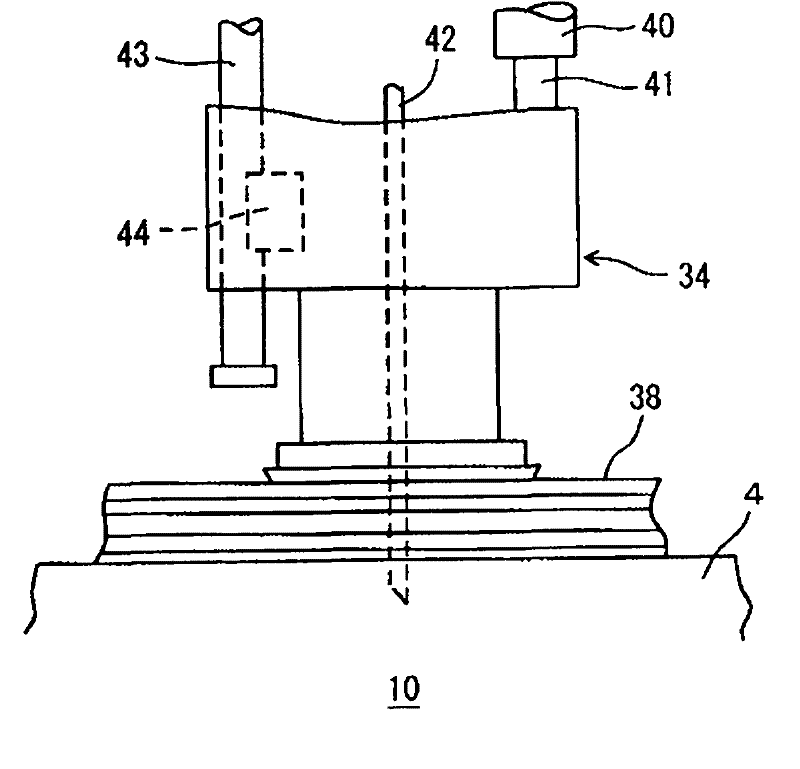

[0052] Figure 1 to Figure 4 Represent the cutting device 2 of embodiment among, Figure 5 , Figure 6 A cutting device 3 of a modified example is shown in . In each figure, 4 is a cutting table, and a pick-up table 6 is provided on the downstream side thereof, and a clothing material transfer table 8 is provided on the upstream side, and the material to be cut is moved between them by a conveyor not shown. In addition, among the materials to be cut, the thickness of each piece of leather, or a plurality of laminated fabrics, etc., is less than 1 cm when it is thin, and about several cm when it is thick. Also there are thicker leathers and thinner leathers in leather. In addition, the pick-up table 6 and the clothing mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com