Water mixing device for automatic constant-temperature water mixing valve

A thermostatic water mixing valve and water mixing technology, applied in valve devices, multi-way valves, engine components, etc., can solve the problems of small change in mixed water, inability to output, and large temperature sensing area of thermal actuators. , to achieve the effect of small size, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

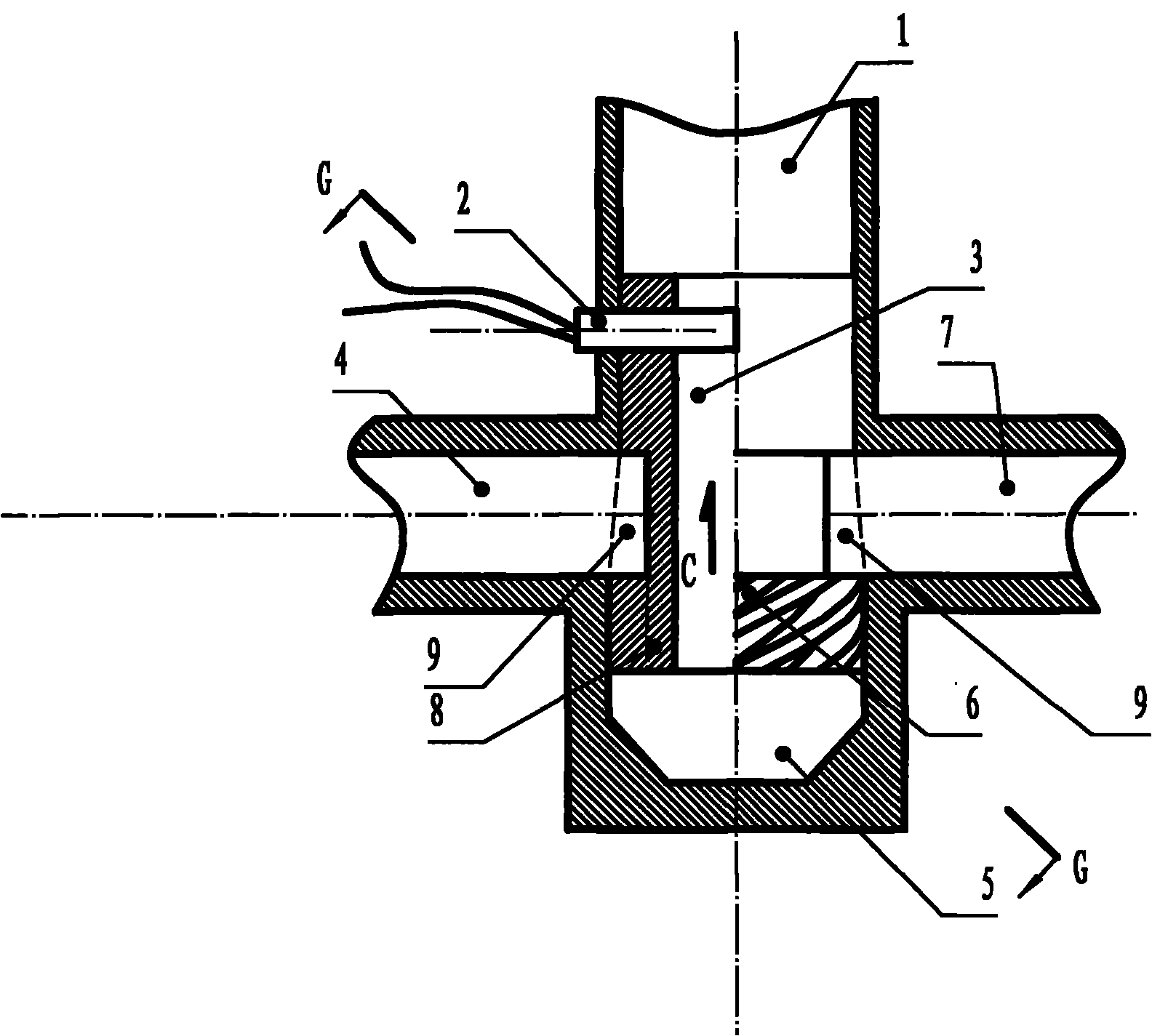

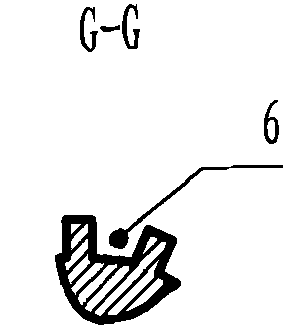

[0018] Example 1. refer to figure 1 , figure 2 , the present embodiment is a water mixing device for an automatic thermostatic water mixing valve, comprising a cold water inlet 7, a hot water inlet 4, a mixing chamber 5 and a mixed water outlet 1, the cold water inlet 7, the hot water inlet 4 Between the mixing chamber 5, there is a water flow vortex generator 8.

[0019] There are eight swirl grooves 6 on the water flow swirl generator 8 in this embodiment, the swirl grooves 6 are helical, the helix angle is 30 degrees, the average width of the swirl grooves 6 is 2 mm, and the depth of the swirl grooves 6 is 2.7 mm. . Each vortex groove 6 is 1 / 5 circle. The major diameter of the cylindrical helix formed by eight vortex grooves 6 is 18.5 millimeters,

[0020] In order to make the cold and hot water mix more evenly, the outflow direction C of the mixed water in this embodiment is opposite to the spiral direction of the vortex groove 6 . Mixing chamber 5 is " U " shape, a...

Embodiment 2

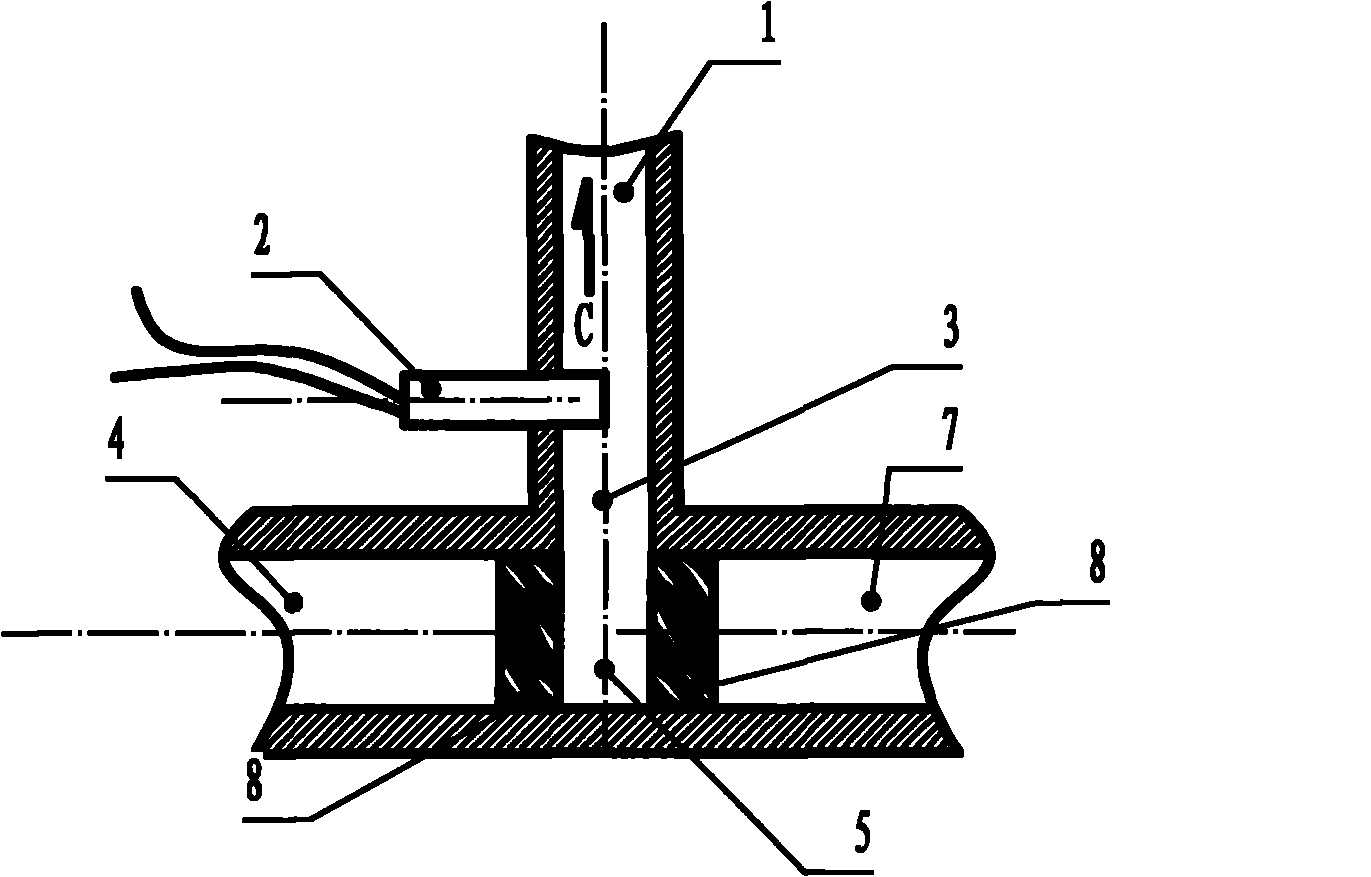

[0024] Example 2. refer to image 3 , the present embodiment is a water mixing device for an automatic thermostatic water mixing valve, including a cold water inlet 7, a hot water inlet 4, a mixing chamber 5 and a mixed water outlet 1, and there is a water flow vortex at the cold water inlet 7 Generator 8, another water flow vortex generator 8 is also arranged at hot water inlet 4 places. The cold water inlet 7 and the hot water inlet 4 communicate with the mixing chamber 5 through the two water flow vortex generators 8 . The helical directions of the vortex grooves 6 on the two water vortex generators 8 are the same, but the flow helical directions of the cold and hot water flowing out of the two water vortex generators 8 are opposite.

[0025] In the present embodiment, there are six vortex grooves 6 on the water flow vortex generator 8, the vortex grooves 6 are helical, the helix angle is 20 degrees, the average width of the vortex grooves 6 is 1.5 millimeters, and the de...

Embodiment 3

[0028] Example 3. refer to Figure 4 , the present embodiment is a water mixing device for an automatic thermostatic water mixing valve, comprising a cold water inlet 7, a hot water inlet 4, a mixing chamber 5 and a mixed water outlet 1, the cold water inlet 7, the hot water inlet 4 Between the mixing chamber 5, there is a water flow vortex generator 8.

[0029] There are eight swirl grooves 6 on the water flow swirl generator 8 in this embodiment, the swirl grooves 6 are helical, the helix angle is 30 degrees, the average width of the swirl grooves 6 is 2 mm, and the depth of the swirl grooves 6 is 2.7 mm. . Each vortex groove 6 is 1 / 5 circle. The major diameter of the cylindrical helix formed by eight vortex grooves 6 is 18.5 millimeters,

[0030] Mixing chamber 5 is " U " shape, and its " U " mouth diameter is 18.5 millimeters, and mixing chamber 5 is deep 20 millimeters. Its "U" bottom outlet has a diameter of 9mm.

[0031] Cold water and hot water flow respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com