Regeneration systems for softeners and mixed beds

A regeneration system and softener technology, applied in ion exchange regeneration, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of time-consuming, reduced regeneration effect, and cumbersome operation, so as to reduce production costs and save floor space. , the effect of saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

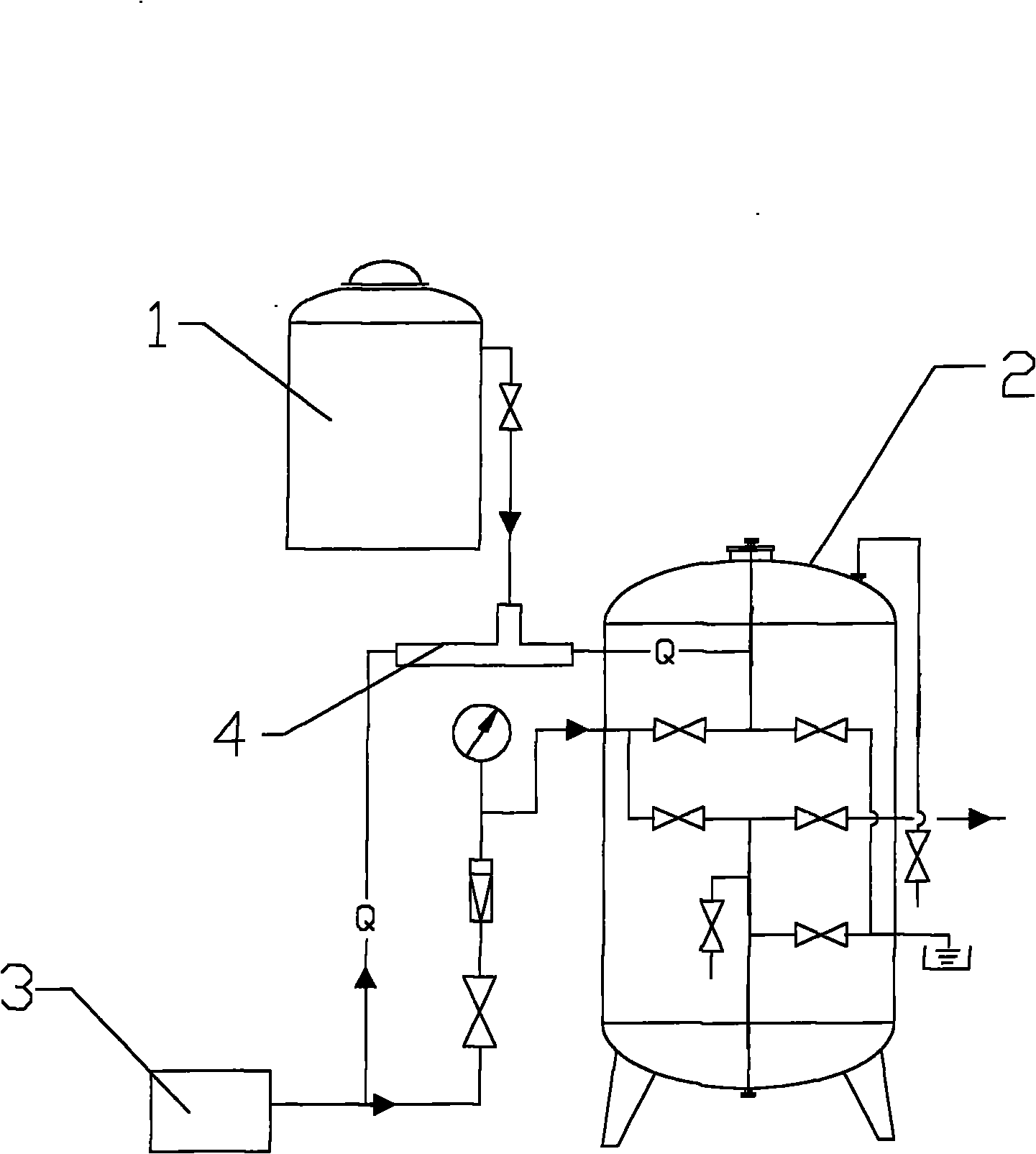

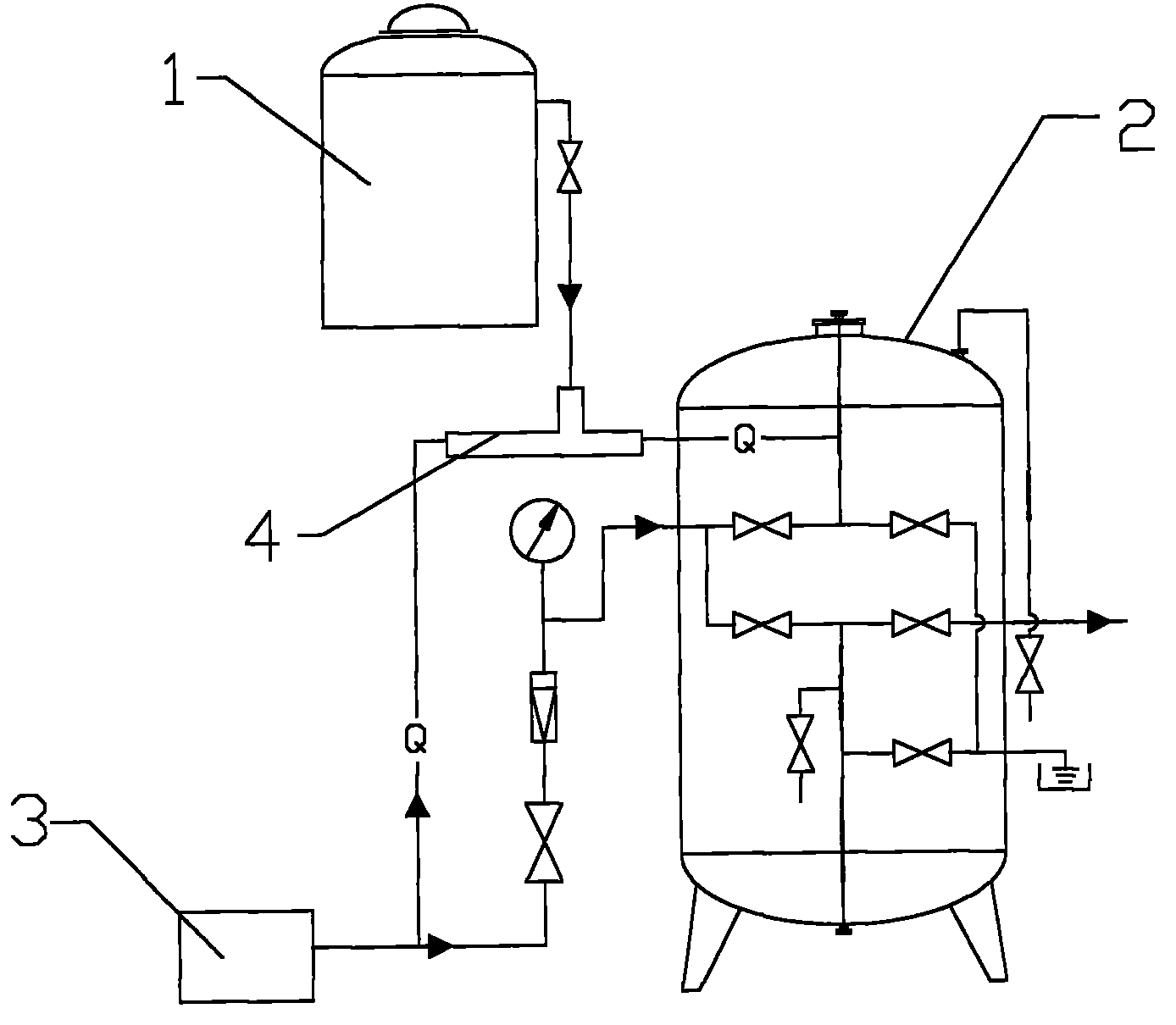

[0011] A regeneration system for a softener, including a softener 1, a concentrated solution storage tank 2, a water pump 3, and an ejector 4. One inlet of the ejector 4 is connected to the outlet of the water pump 3, and the other inlet is connected to the outlet of the concentrated solution storage tank 2. The outlet is connected, and the outlet of the ejector 4 is connected with the inlet of the softener 1, such as figure 1 shown.

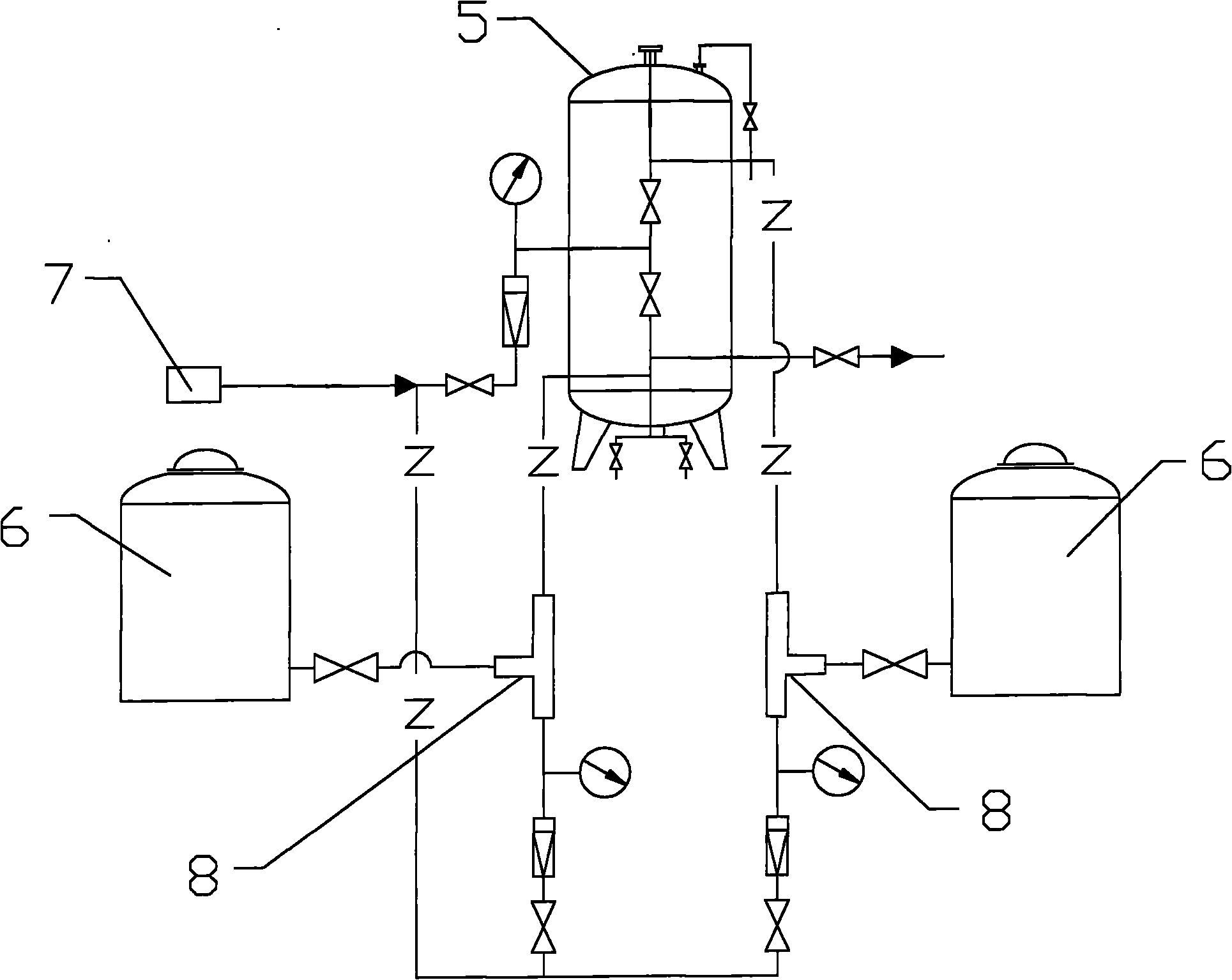

[0012] A mixed bed regeneration system, comprising a mixed bed 5, a concentrated solution storage tank 6, a water pump 7, and an ejector 8, one inlet of the ejector 8 is connected to the outlet of the water pump 7, and the other inlet is connected to the outlet of the concentrated solution storage tank 6 The outlets are connected, and the outlet of the ejector 8 is connected with the inlet of the mixed bed 5 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com